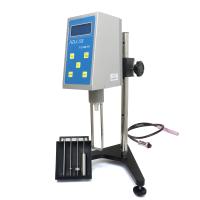

XIONGFA NDJ-5S Digital Rotational Viscometer Laboratory Rotational Viscometer

XIONGFA NDJ-5S Digital Rotational Viscometer JB/T9357 standard design, measuring the tack resistance of liquids and the absolute viscosity measurement range of liquids 10~100000mPa · s, suitable for measuring the viscosity of various fluids such as oils, paints, food, Adhesives and cosmetics.

XIONGFA

XIONGFA-

NIRUN NTV-P3RV Digital Viscometer Fluid Viscosity Tester 40M mpa.s

$ 5105.00 -

NIRUN NTV-P3HB Digital Viscometer High Viscosity-Meter 104M mpa.s

$ 5105.00 -

Pingxuan HBTV-2C digital display Rotational Viscometer 320~320000000Mpa · s

$ 1414.00 -

Pingxuan LVTV-2C Digital Rotational Viscometer 1~ 6000000mPa·s

$ 1114.00 -

NIRUN DV-79 + Pro Digital Viscometer Measurement range 1~ 75 million cP

$ 2628.00

Instrument Introduction

Digital Rotational Viscometer is a new type of digital instrument developed and developed based on monolithic microprocessor technology, which is used to determine the viscous resistance of liquids and the absolute viscosity of liquids. Compared with similar instruments, it has the advantages of high measurement accuracy, stable viscosity value display, easy to read, easy operation, good anti-interference performance, etc., and is widely used to determine the viscosity of various fluids such as grease, paint, food, adhesives and cosmetics.

According to the ministerial standard JB/T 9357 Laboratory Rotational Viscometer general technical conditions for implementation and processing.

Serial models

| Model | NDJ-5S | NDJ-8S |

| Measuring range | 10~100000mPa·s | 10 ~2000000mPa·s |

| Rotor specifications | No. 1-4 rotor The optional No. 0 rotor can measure low viscosity to 0.1mPa.s | |

| Rotor speed | 6、12、30、60cpm | 0.3、0.6、1.5、3、6、12、30、60cpm |

| Automatic | The appropriate rotor number and speed can be selected automatically | |

| Select the operation interface | Chinese/English | |

| Reading stabilization cursor | When the vertical bar cursor is full, the reading is basically stable | |

| Measurement accuracy | ±2% (Newtonian liquid) | |

| Temperature accuracy | 0.1℃ | |

Operating Principle

The programmable motor drives the shaft to rotate stably according to the speed given by the program, and then drives the standard rotor to rotate through the button torque sensor. When the rotor rotates in a certain liquid, due to the viscosity of the liquid, the rotor is subjected to a torque force proportional to the viscosity, and the viscosity of the liquid can be obtained by measuring the magnitude of this torque through the torque sensor. In order to extend the measuring range, it is equipped with four standard rotors and four speed gears given.

2. To measure a wide viscosity range of 10mPa·s~100000mPa·s, different combinations of rotors and speeds are required. The speed of this instrument is divided into four gears, and the rotor is also divided into four different specifications. From a variety of different combinations, any viscosity value in the measured range can be measured. In the middle of the panel, there are 5 key combinations: up, down, left, right, and enter. When the machine is turned on, the instrument displays the rotor and speed values of the last operation, which can be viewed and selected by the up and down buttons. To measure a certain range of viscosity, a certain size of rotor and a certain speed are required, which can be selected and set by the up and down keys and the left and right buttons. You can first estimate the approximate viscosity of the liquid to be measured, and select the appropriate rotor and speed. Install and set the rotor and rotational speed, press enter to start the measurement. The instrument has an internal data memory that stores the measuring range of the instrument, the default rotor, speed, various coefficients, and test data. The microcontroller controls the rotational speed of the motor according to the user's choice. In addition, the instrument is also equipped with RS232 communication port, which can carry out two-way data communication with the computer.

3. The rotor protection frame of the instrument is used for stable measurement and protection of the rotor, and the use of the rotor protection frame for measurement can obtain more stable test results.

Installation

1. Take out the bracket and pillar from the carton, put the nylon pad on the pillar and screw it into the screw hole at the back of the bracket, tighten the strut with a wrench to prevent the strut from rotating, and face the toothed surface of the strut in front of the bracket.

2. Take out the viscometer from the instrument box, install the lifting device of the viscometer on the pillar, adjust the tightening screws, not too loose, not too tight, rotate the lifting knob, so that it can rise and fall, and it is advisable to be tight, in case the viscometer will automatically fall.

3. Unscrew the protective cap screws at the lower end of the product and remove the yellow protective cap.

4. Observe the horizontal bubble and adjust the horizontal adjustment screw at the lower part of the bracket so that the bubble is in the middle of the horizontal bubble, indicating that the product is close to the level. Plug in the power cord.

Precautions

1. This instrument is suitable for use at room temperature, and the temperature of the measured sample should be within ±0.1°C, otherwise the accuracy of the measurement will be seriously affected.

2. The instrument needs to be used within the specified Voltage and frequency and the allowable error range, otherwise the measurement accuracy will be affected.

3. When loading and unloading the rotor, it should be operated carefully, the connecting screw should be slightly lifted, do not use too much force, and do not let the rotor be stressed laterally, so as to avoid the rotor from bending.

4. Do not put the instrument on its side or down after installing the rotor.

5. The connecting screw and rotor connection end face and thread should be kept clean, otherwise the correct connection of the rotor and the stability of rotation will be affected.

5. When the instrument is lifted, it should be supported by hand to prevent the instrument from falling with its own weight. After each use, the rotor should be cleaned in time (rotor cleaning should not be carried out on the instrument). After cleaning, it should be properly placed in the rotor box.

6. After installing the rotor, it must not be "rotated" without liquid, so as not to damage the shaft tip.

7. Do not disassemble or adjust the instrument parts at will, and do not fill the lubricating oil by yourself.

8. When the instrument is moved and transported, the yellow protective cap should be put on, the connecting screw should be lifted, and the screws on the cap should be tightened.

Note: Many of the suspensions, emulsions, polymers and other high-viscosity liquids are "non-Newtonian liquids", and the apparent viscosity value changes with the change of shear speed and time, so it is normal for the results to be inconsistent under different rotor, speed and time, not that the instrument is inaccurate (generally the determination of non-Newtonian liquids should specify the rotor, speed and time).

XIONGFA NDJ-5S Digital Rotational ViscoMeterSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 10~100000mPa·s |

| Rotor specification | 1 #, 2 #, 3 #, 4 #(0 #optional) |

| Rotor speed | 6/12/30/60rpm |

| Automatic scan function | Automatically select the appropriate rotor number and Rotation speed |

| Operating language | Chinese/English |

| Readout stability cursor | When the vertical bar cursor is full, the display reading is basically stable |

| Measurement Accuracy | ±2%F.S |

| Temperature Accuracy | 0.1℃ |

| Power supply Voltage | AC 220V +/- 10% 50Hz +/- 10% |

| Operating temperature | 5~35℃ |

| Dimensions | 370*325*280mm |

| Net Weight | 6.8㎏ |

| Allowable Relative Humidity | ≤80% |

XIONGFA NDJ-5S Digital Rotational ViscoMeter Packing list

Test host X1, lifting column X1, base X1, rotor X1 No. 1 to 4, rotor protective cover X1, wrench X1, power cord X1, certificate of conformity, manual.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- How does a Rotational Viscometer reduce measurement errors?

- Principle, application and selection of coaxial cylinder Rotational Viscometer

- Shear Stress Peak Graph Method for Determination of Ink Rheology

- The working principle and application of viscosity meter

- What are non-Newtonian fluids?

- Rotational viscometer data bias, these key factors to pay attention to

- A Brief Description of Pseudoplastic Fluids and Expansive Fluids

- Method for Determination of Ink Rheology: Rheological Curve Thixotropic Ring Area Method

- The relationship between paste ink and viscosity (viscosity)

- Definitions of four different viscosities

NDJ-5S

NDJ-5S