PNSHAR PN-PIDF inks printing Rub Resistance Tester

According to GBT7706 ink layer abrasion resistance testing, it is dedicated to the wear resistance test of printing ink layer, PS plate photosensitive layer, etc., which fully meets the national standard compatibility international.

PNshar

PNshar-

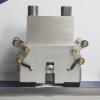

PUSHEN NMC-II Friction Tester Printing ink abrasion resistance testing

$ 1272.00 -

TRUIT TR 5303 Ink Rub Resistance Tester

$ 1082.00 -

JINGHUAYIQI LD-YMT-B inks Wear Resistance Rub Resistance Tester printing ink layer friction resistance Tester, American standard

$ 639.00 -

CHINA NBC-8507 Ink Rub Resistance Tester printing, color printing box wear resistance

$ 572.00 -

HUIDA HD-6010 Ink Rub Resistance Tester Electric Rub Resistance Tester

$ 766.00

product description

PN-PIDF ink printing decolorization testing machine is also called abrasion resistance meter and friction testing machine. It is a testing instrument for the abrasion resistance of ink layer developed by our company in accordance with the national standard GB/T 7706. It is mainly suitable for testing the wear resistance of the printing ink layer of printed matter, the wear resistance of the PS plate photosensitive layer and the wear resistance of the surface coating of related products.

Principle: Fix the friction paper on the friction body, fix the sample to be tested on the friction table, start the instrument, the friction body rubs the sample at a certain speed, and the counter counts once after each reciprocating cycle. When the set value is reached, After a certain number of frictions, the test ends. The wear resistance of the sample is judged by comparing the changes in ink density before and after friction.

This instrument adopts modern mechanical design concepts and ergonomic design principles, and is carefully designed and manufactured using professional microcomputer processing technology. It is a new generation ink printing decolorization testing machine with novel design, easy use, excellent performance, and elegant appearance. .

Implementation standards

GB/T 7706, ASTM D5264, TAPPI T830

Features

1. Adopt new module circuit design, with WIFI Internet of Things function. After being connected to the Internet, the test results can be saved to the cloud server, and can be queried and generated through the dedicated QMS quality management system;

2. Enter the number of frictions into the control system before the test, and the test can be automatically controlled, and a buzzer will sound after each test is completed;

3. The control system has a power-off memory function. After each power-on, the parameter status entered before the last power-off will be maintained;

4. The actuator uses a high-precision gear reduction micro motor to drive the friction body to perform linear reciprocating friction motion;

5. Fully meet the requirements of national standards and be compatible with international standards.

PNshar PN-PIDF Inks printing Rub Resistance TesterSpecifications

| LIST | VALUE |

|---|---|

| Power | AC220V±10% 2A 50Hz |

| Friction paper size | Width 50mm, general friction paper 210 × 50mm |

| Friction sample size | The width is greater than the width of the friction paper. Generally, the friction sample is 280 × 60mm. |

| number of times | 1~999999 |

| friction load | 20N; 2Lb and 4Lb three loads |

| friction stroke | Approx. 60mm |

| Display | 5 "Color touchscreen |

| Operating Environment | Indoor temperature (20 +/- 10) ℃; Relative Humidity < 85% |

| Dimensions | 335*295*295mm |

| Weight | About 16.6kg |

PNshar PN-PIDF Inks printing Rub Resistance Tester Packing list

machine X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What is the permeability of ink?

- Failure of Flexographic Printing and Remedy Method

- What faults are prone to photogravure printing? What remedies are there?

- Transfer phase of ink transport on the printing press

PN-PIDF

PN-PIDF