Defelsko PosiTest G Coating Thickness Gauge for Eletroplating, thin paint layer, steel phosphating film thickness measurement with certificate

0~200µm dial type coated platings Thickness Gauge, no power supply, underwater testing, explosion-proof, can measure the surface sample Coating thickness.

Defelsko

Defelsko-

CHINA CTG-802-3000FN Split iron-aluminum dual-use Coating Thickness Gauge (large range)

$ 250.00 -

Defelsko PosiTector 6000 FT1 Portable platings Thickness Gauge, integrated magnetic Thickness Gauge

$ 1000.00 -

IWAVE WH91 split coating Film thickness meter Iron base

$ 182.00 -

LEEB probe (with printer) F1 magnetic Induction probe with leeb242 Coating Thickness Gauge

Login -

Defelsko PosiTector 6000 NKS3 Coating Thickness Gauge eddy current principle, special probe for thick coatings

$ 1721.00

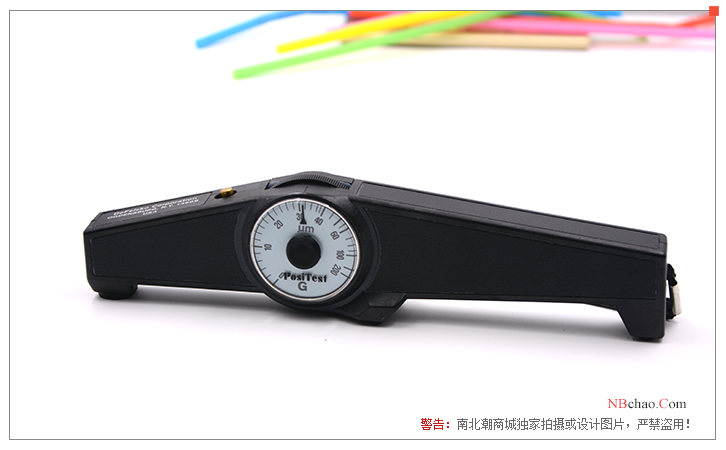

Overview

Defelsko PosiTest G Coating Thickness Gauge is a pointer coating Thickness Gauge produced and developed by Defelsko in the United States, with a simple appearance and structure, no battery power supply, and a pointer gauge and sound to indicate the completion of the measurement, small size, and easy to carry.The PosiTest G Coating Thickness Gauge is suitable for measurementsThe non-magnetic coating on steel is suitable for thickness measurement of electroplating, thin paint film, and phosphate film on steel, with a measurement range of 0~200 microns.

Features

Precision

--Each gauge comes with a calibration certificate traceable to the U.S. IST

--Each model can be matched with calibration standards and procedures

--High wear-resistant carbide probe is conducive to the durability of service life and the durability of excellent accuracy

--The adjustable center of the dial makes it easy and convenient to adjust the adjustment

--Comply with international and domestic (CN) testing standards

durable

durable

--Special textured shell, no fear of mechanical impact, water, acid or solvent

--Unique overall design, full support, forced positioning, no possibility of rotation and movement during the measurement process

--Choose to measure with sufficient support or use only the probe contact coating of the front measuring arm

--Long-lasting magnetism of rare earth cobalt magnets, no batteries required

--Explosion-proof, very safe

--1 year guarantee

Easy to use

--Equipped with visual prompts and audible prompts to remind the completion of the measurement

--The "V" groove probe housing design and unique instrument base facilitate positioning and measurement on cylindrical samples

--Compact, lightweight, precise balance, not affected by gravity (gravity), can be used anywhere

--GO/O-GO (Start/Disable) buttons can be preset for quick measurements

--Probe placement and dial rotation are just one finger operation

--The included wrist strap and instructions are kept in a high-quality leather case

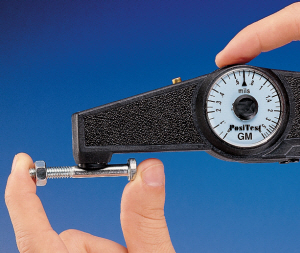

Live shot

PosiTest G Mechanical Coating Thickness Gauge Operation

1) Place the coating gauge vertically on the object to be measured, so that the probe can touch the surface of the object to be measured.

2) PressPosiTest G Coating Thickness GaugeGO/NO-GO button (i.e., gold button on the gauge)

3) Gently shake the wheel until you hear a "click", and the thickness indicated by the dial pointer at this moment is the thickness of the coating to be measured.

Overview of parameters

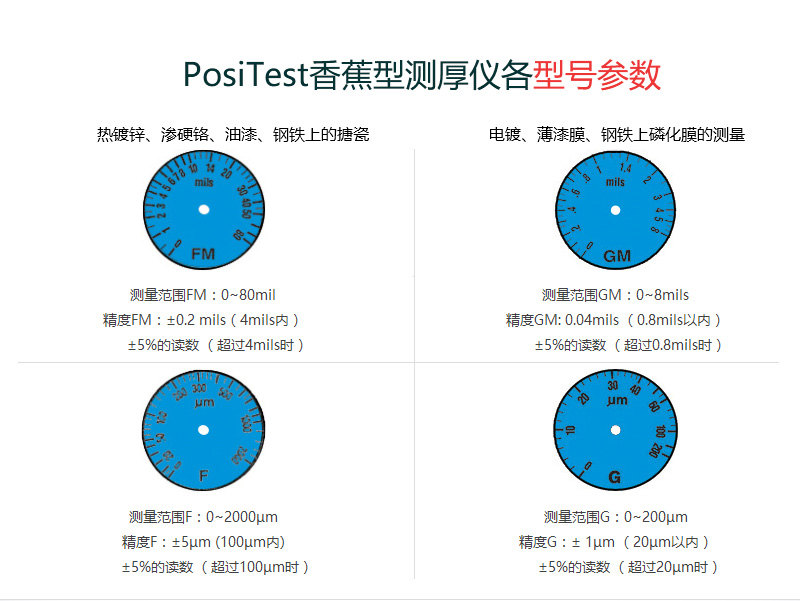

| Used for: hot-dip galvanizing, hard chrome, paint, enamel on steel | Used for: electroplating, thin paint film, measurement of phosphating film on steel |

|

|

Measuring range FM: 0~80mil Accuracy FM: ±0.2 mils (within 4mils) ±5% of reading (over 4mils) | Measuring range GM: 0~8mils Accuracy GM: 0.04mils (within 0.8mils) ±5% of reading (over 0.8mils) |

|

|

Measuring range F: 0~2000μm Accuracy F: ±5μm (within 100μm) ±5% of reading (above 100μm) | Measuring range G: 0~200μm Accuracy G: ± 1μm (within 20μm) ±5% of reading (above 20μm) |

Defelsko PosiTest G Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~200µm |

| margin of error | ±5% |

| application | Eletroplating, thin paint film, phosphating film on steel measurement |

Defelsko PosiTest G Coating Thickness Gauge Packing list

Thickness gauge × 1, calibrating certificate × 1, English operation manual × 1, protective bag × 1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- Nondestructive measurement Coating thickness

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- AbolishASTM G12-07-2013

- AbolishISO 2808-2007

PosiTest G

PosiTest G

PosiTest F

PosiTest F