AOTAI AT-700 high-precision Ultrasonic Thickness Gauge

Ultrasonic Thickness Gauge AT -700, is a new generation of smart Ultrasonic Thickness Gauge, Measurement range: 0.75~ 300mm (probe decision), resolution: 0.1/0, AT-700 high-precision Ultrasonic Thickness Gauge can measure the thickness of metals, Glass, ceramics and other materials.

AoTai

AoTai-

AMITTARI AT-140A Ultrasonic Thickness Gauge 0.1mm resolution Probe diameter φ 8mm, 5HZ

$ 332.00 -

PRUT600 Ultrasonic Thickness Gauge penetrating coating thickness measurement

Login -

KAIRDA N02 Ultrasonic Thickness Gauge Probe for measurement of coarse crystal materials such as cast iron

Login -

D2012 Ultrasonic Thickness Gauge Probe

$ 214.00 -

QILI UT400 Ultrasonic Thickness Gauge High Accuracy 0.001mm Metal Plastic Thickness measurement

$ 242.00

Introduction

Ultrasonic Thickness Gauge AT-700 is a new generation of intelligent ultrasonic Thickness Gauge, using new high-performance, low-power microprocessor technology, based on the ultrasonic measurement principle, it can measure the thickness of metal, glass, ceramics and other materials, and measure the sound velocity of materials. It is widely used in thickness measurement of various plates, pipe wall thicknesses, boiler vessel wall thicknesses, various pipes and pressure vessels, and monitors the degree of thinning after corrosion during use.

Ultrasonic Thickness Gauge AT--700 Main Functions:

It is suitable for measuring the thickness of metals (e.g. steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, fiberglass, and any other good conductor of ultrasound

It can be equipped with a variety of dual element transducers with different frequencies and different element sizes

It has the functions of zero point calibration and two-point calibration of the probe, which can automatically correct the system error

Known thicknesses can be used to backmeasure the speed of sound to improve measurement accuracy

It has a coupling status prompt function

There is an LED backlit display for easy use in low-light environments

There is a residual battery indication function, which can display the remaining battery power in real time

It has power-saving functions such as automatic sleep and automatic shutdown

Small, portable, and highly reliable, it is suitable for harsh operating environments and is resistant to vibration, shock and electromagnetic interference

Ultrasonic Thickness Gauge AT-700 optional probes and parameters:

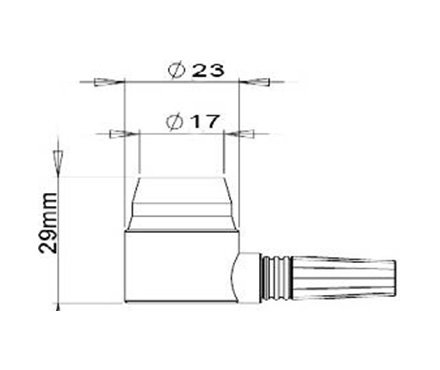

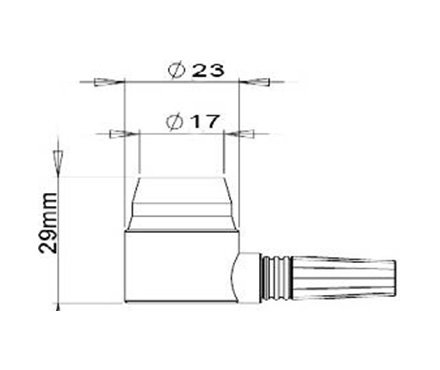

name | Model | Frequency (MHZ) | Probe diameter | Measuring range | The surface temperature of the object to be measured | Description |

Standard probes | N05 | 5 | 10mm | 0.75mm~300mm(Steel) | -10~60℃ | Use at room temperature (<60°C) |

N05/90 | ||||||

Coarse-grain probes | N02 | 2 | 12mm | 3.0-300.0mm(Steel) | -10~60℃ | It is used for measuring coarse-grained materials such as cast iron |

Microdiameter probes | N07 | 7 | 6mm | 0.65mm~260mm(Steel) | -10~60℃ | It is used for the measurement of thin walls and small arcs, |

High temperature probes | HT5 | 5 | 4mm | 1.0mm~200mm(Steel) | -10~400℃ | It is used for the measurement of materials with temperatures less than 400°C |

Advantages of Ultrasonic Thickness Gauge AT-700: | Other models of Thickness Gauges at the same price |

1. Menu-based operation, high-brightness LCD display, With LED backlight | The broken code EL display has high power consumption and is not clear in gray and dark environments |

2. The sound velocity is adjustable, and a variety of materials can be measured | The low-priced manufacturer only has 5920 a steel speed of sound |

3. It can be equipped with a variety of probes (coarse grain, small diameter, high temperature) without calibration, and automatic identification and calibration | Multiple probes cannot be automatically recognized |

4. There is a minimum capture indication | There is no minimum thickness capture capability |

5. It can store 500 sets of data and 5 files | Only 50~100 sets of data can be stored |

6. The internal use of a highly integrated motherboard, the chips are all imported from the original, and the performance is stable! | Most of them use two circuit boards, and most of the domestic (CN) devices are used, and the performance is unstable |

AoTai AT-700 High-Precision Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 0.75~ 300mm (probe determined) |

| Probe style | Split probe |

| Probe Frequency | 5MHz probe |

| Speed of sound | 1000~9999m/s |

| Measurement error | ±(0.5%H+0.04)mm |

| Display resolution | 0.1/0.01mm |

| Lower limit of pipe measurement | Should be 20 * 3mm (5MHz probe); the error of indication should not exceed +/- 0.1 mm |

| Probe contact temperature | -10~60℃ |

| Data storage | 500 data read values stored, viewed, and deleted |

| Operating Time | 250H (no backlight) |

| Operating language | Chinese |

| Display | LCD screen |

| Host size | 150*74*32mm |

| Weight | 238g |

| Application | Metals (e.g. steel, cast iron, aluminium, copper, etc.), plastics, ceramics, Glass, fiberglass and Miscellaneous Thickness of any good conductor of ultrasonic waves |

| Power Supply | AA type alkaline battery 1.5V (2 *) |

| unit system | mm/inch |

| minimum thickness value capture capability | Capable of capturing minimum thickness values |

| Measurement speed | 4 times/sec for single point measurement, 20 times/sec for scanning mode |

| Calibrating block | 4.0 mm (steel) |

AoTai AT-700 High-Precision Ultrasonic Thickness Gauge Packing list

Host X1, coupling agent X1, battery 2 (non-aviation) X2, 4.0 mm steel calibrated block X1, 5MHz probe X1, NDT310 host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveJJF 1224-2009

- ActiveJJF 1126-2004

- ActiveJB/T 11604-2013

- ASTM E797-2021

- AbolishGB/T 11344-2008

- JJF 1126-2004

- AbolishZB N 77001-1989

AT-700

AT-700