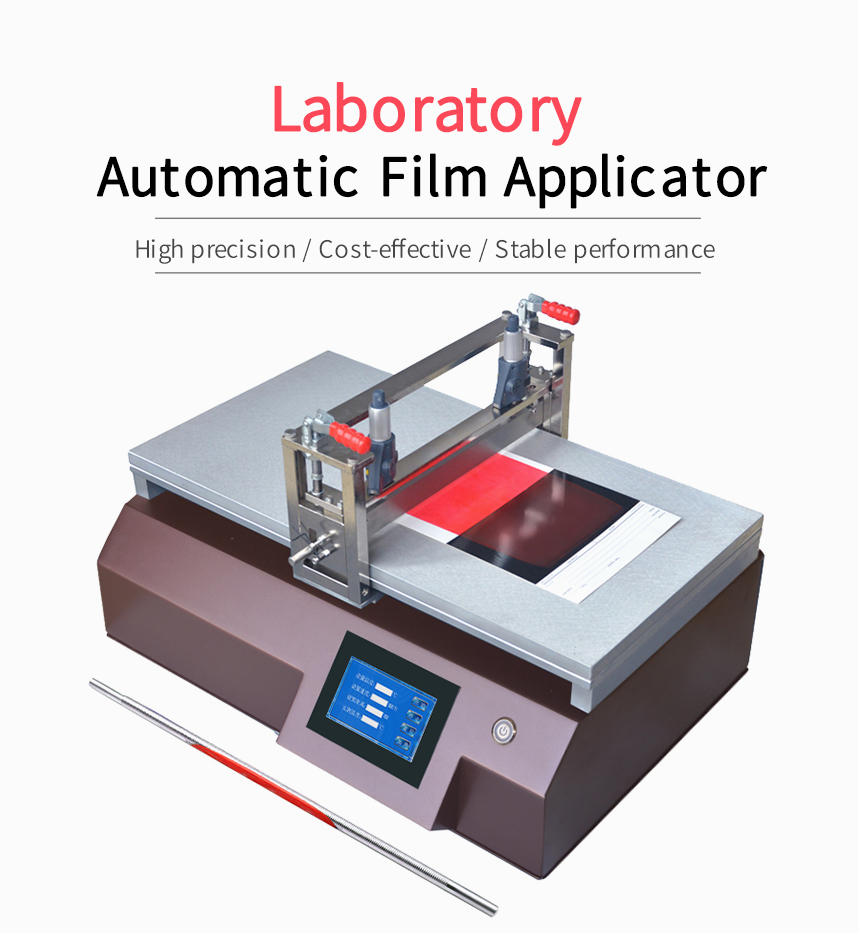

Food film experimental Coater 150μm film thickness Film Applicator Kit

This food film experimental coater is equipped with imported OSP150 rod, film thickness 150 microns, with heating and vacuum adsorption functions, can be used for film substrate film experiment, matching drawdown blade range 0~10mm.

zy

zy-

China NBC-X4-DJ7 Floor Type Automatic Film Applicator Effective film area 700 * 1300mm

$ 21384.00 -

NBC-XF200S Plate slot die Coater slot-die Extrusion Automatic Film Applicator

$ 32909.00 -

HuiNuo TM3300AK/02 Perovskite Special Automatic Film Applicator with Air Knife + Air Knife Holder 40 * 30cm

$ 5597.00 -

HUINUO TM1200pro High-precision Laboratory Drawdown Blade Film Coater Coating Machine with Heat Function

$ 3071.00 -

Huinuo TM3300/06 wire rod scraper heating vacuum adsorption coating machine, coating area 600 * 800mm

Login

product description

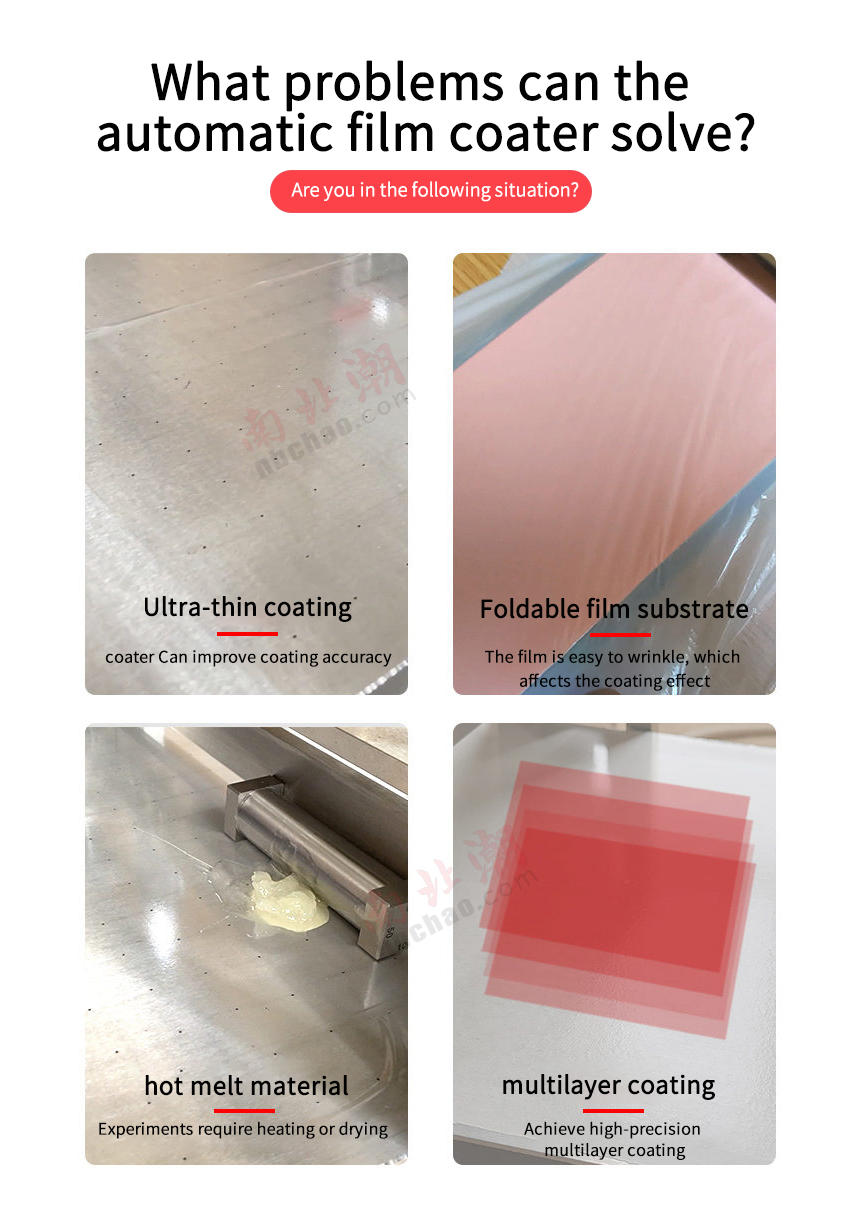

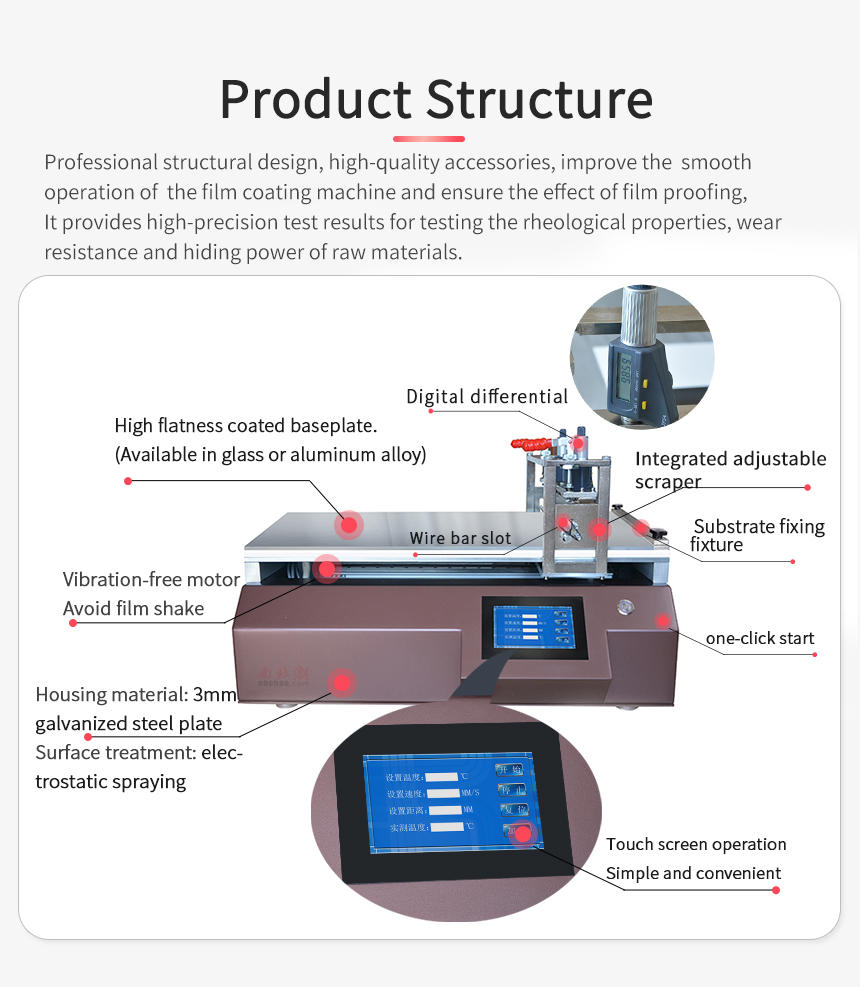

The TBJ-X experimental small coating testing machine all uses imported accessories and is very affordable. It has been favored by many multinational R&D institutions, as well as many well-known universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure, the coating and gluing effect is ensured, and the uniformity and stability of the coating and gluing are ensured.

Since the main factors that affect the coating film are the coating speed and the pressure exerted on the Film Applicator, the coatings applied manually are often inconsistent, especially the differences between different people are even greater. This makes it difficult to compare test results between samples. Our company's automatic Film Applicator is carefully designed to allow operators to easily apply precise wet films on different substrates, greatly improving the reproducibility of coating films.

This automatic coating machine comes standard with imported OSP wire rods, which are used for scraping and coating food films with a thickness of 150 μm.

Features

The laboratory small coating machines all use imported accessories and are very cheap. They have been favored by many multinational R&D institutions and many familiar universities at home and abroad.

By controlling the speed and stable pressure, the coating effect is ensured, and the uniformity and stability of the coating are ensured.

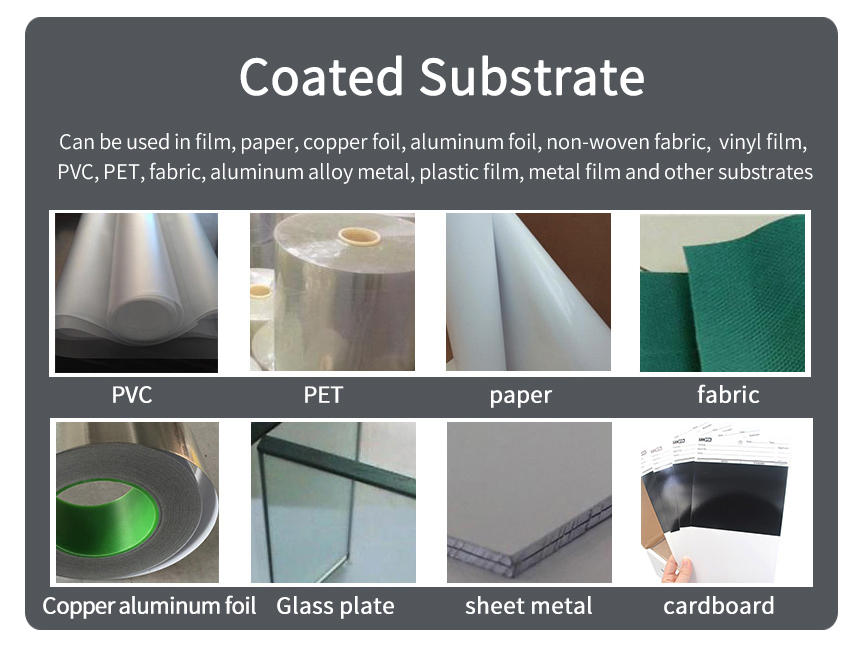

Coating experiments can be carried out on various flat materials such as paper, plastic, metal, PVC, PET, cloth, and aluminum alloy plates.

Why do we need imported wire rods?

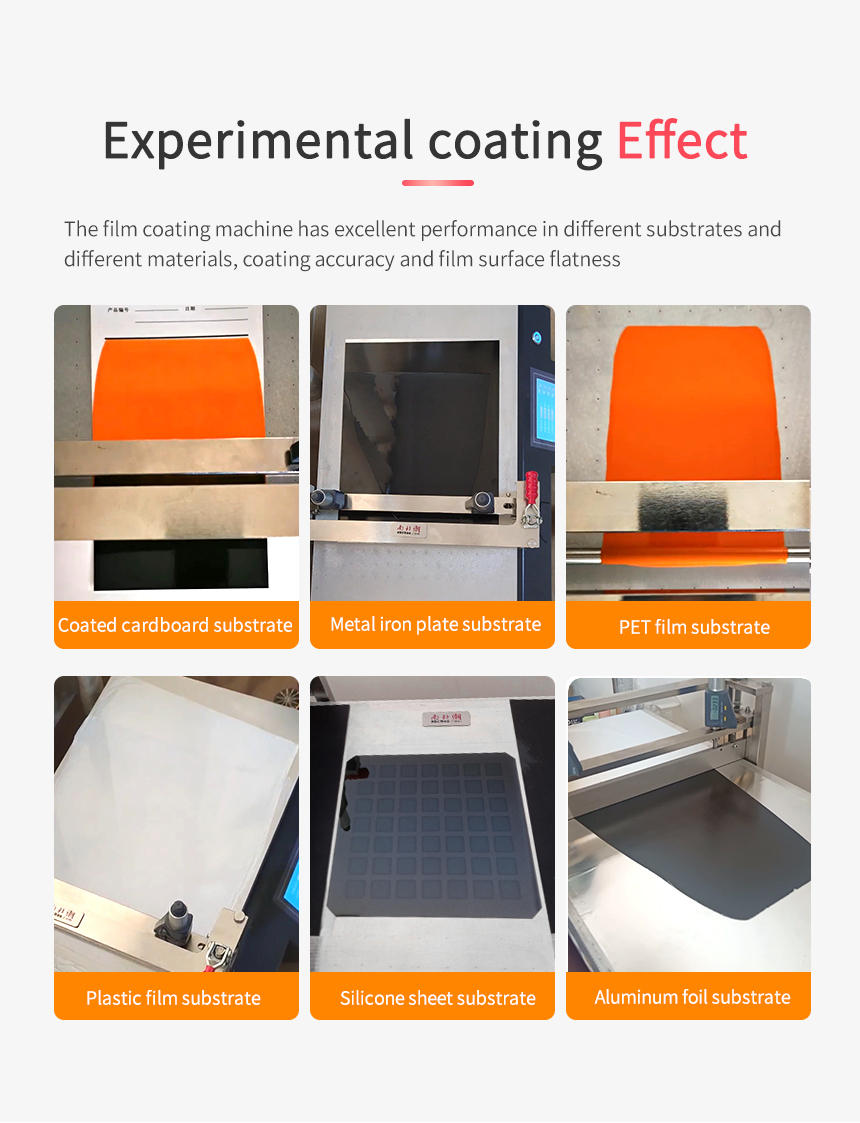

The experimental coating effect is the result of the joint action of the coating machine and the wire rod. The automatic coating machine can control the speed and pressure of coating, while the wire rod coater/preparator determines the accuracy of the coating film. The coating accuracy of the imported wire rod can be as high as 0.1μm, and the matching imported wire rod can achieve ultra-thin and high-definition coating. Precision coating.

Coating machine type selection table

| Coating machine optional types | Application Notes | Coating film accuracy | Heating temperature | Vacuum configuration |

| Wire rod type | Ordinary model (high-precision coating) | Determined by wire rod, up to 0.1μm | / | / |

| Wire rod + scraper type | Ordinary style+ | The wire rod can reach 0.1μm, and the scraper can reach ±3μm. | / | / |

| Scraper + heating type | The sample needs to be heated, the sample has large particles/high viscosity, and the film thickness is not fixed. | ±3μm | RT~200℃ | / |

| Wire rod + heating type | Sample needs to be heated | Determined by wire rod, up to 0.1μm | RT~200℃ | / |

| Wire rod + scraper + heating type | The sample needs to be heated, the sample has large particles/high viscosity, and the film thickness is not fixed. | The wire rod can reach 0.1μm, and the scraper can reach ±3μm. | RT~200℃ | / |

| Wire rod + vacuum type | Thin film substrate, high-precision coating | Determined by wire rod, up to 0.1μm | / | External |

| Scraper+vacuum type | Thin film substrate, large sample particles/high viscosity, and unstable film thickness | ±3μm | / | External |

| Wire rod + scraper + vacuum type | Thin film substrate, large sample particles/high viscosity, and unstable film thickness | The wire rod can reach 0.1μm, and the scraper can reach ±3μm. | / | External |

| Wire rod + scraper + heating + vacuum type | All-purpose model | The wire rod can reach 0.1μm, and the scraper can reach ±3μm. | RT~200℃ | External |

| Wire rod + heating + vacuum type | Thin film substrates, high-precision coatings, and samples need to be heated | Determined by wire rod, up to 0.1μm | RT~200℃ | External |

| Squeegee + heating + vacuum type | Film substrate, sample with large particles/high viscosity, unstable film thickness, sample needs to be heated | ±3μm | RT~200℃ | External |

| Note: The fabric is breathable, so there is no need to choose the vacuum type. For paper that is difficult to flatten, you need to choose the vacuum adsorption type. | ||||

Optional

zy TBJ-X3+OSP-150/400 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Drawdown blade Accuracy | ±0.003mm |

| Spreader thickness range | 0~10Mm drawdown blade can be lifted |

| Coating speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Coating size | 300*400mm |

| Spreader speed | Digital display, different speeds |

| Vacuum Area | 300 * 400Mm (can be customized) |

| Vacuum aperture | Φ1.2mm |

| Vacuum hole spacing | 20*20mm |

| Drawdown blade | length |

| Coating rod specification | 1 imported 150μm wire rod + 1 China wire rod |

| Host Power | 220V 50Hz |

| Dimensions | 630*410*520mm |

| Weight | Net Weight 65KG |

| speed control | Infinitely variable speed |

| Bottom plate material | aluminum alloy |

| Heating temperature range | RT+~200℃ |

| Temperature Uniformity | ±3℃ |

| Power | 1500W |

| Vacuum pump size | 380*180*280mm |

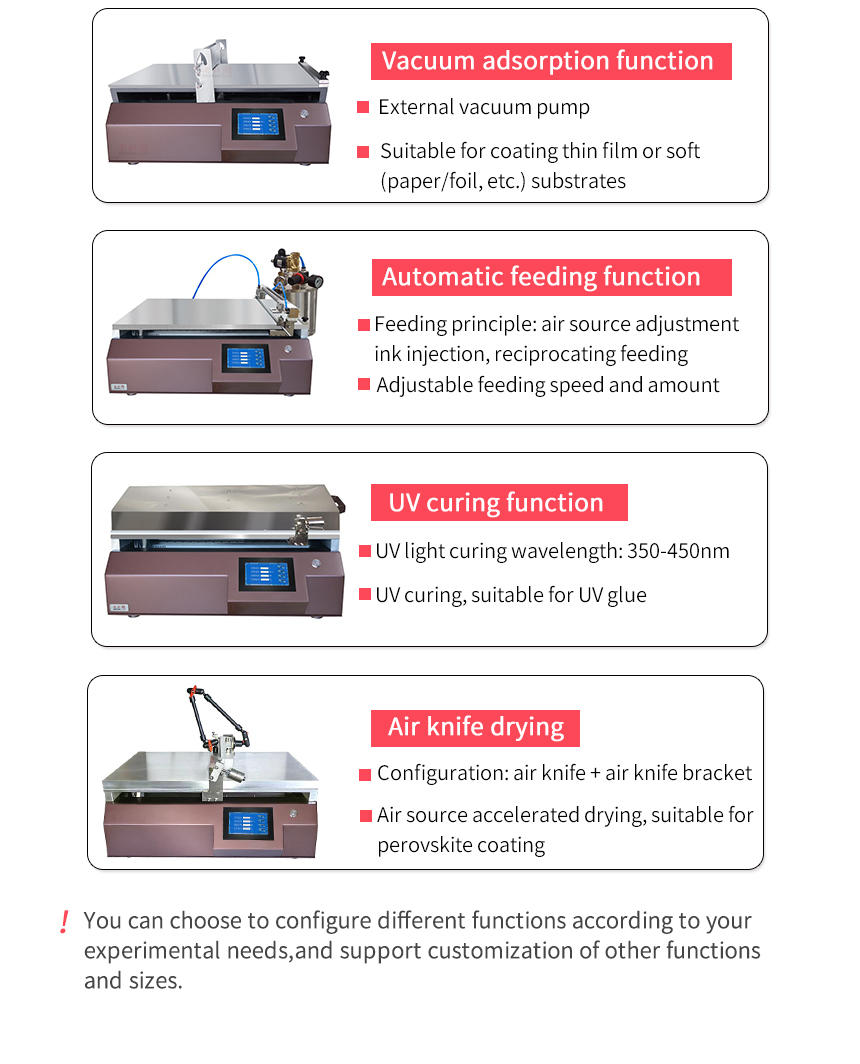

| Customizable function | Jet system device, UV solid-containing device, automatic inking system |

zy TBJ-X3+OSP-150/400 Automatic Film Applicator Packing list

Film Applicator X1, External vacuum pump X1, doctor blade X1, imported wire rod X1, China wire rod X1, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Barrier film primer after UV bonding coating solution [Coating machine case]

- Application and Development Trend of Plasticizers in Coating Industry

- Analysis and application of self-adhesive laboratory coater technology

- Explore the technology and application of polymer sheet coater

- Comparison and Difference Between Offset Press and Film Applicator

TBJ-X3+OSP-150/400

TBJ-X3+OSP-150/400

TBJ-X3-XB

TBJ-X3-XB