TENCAN Powder XQM-0.4A Vertical Planetary Ball mill

TENCAN Powder XQM-0.4A vertical planetary ball mill motor Power 0.25kw, running set total time 1~ 9999min, front and back alternating running time 1~ 999min, XQM-0.4A vertical planetary ball mill can place up to 4 ball milling cans to grind 4 different kinds of samples at the same time, and can also be symmetrically placed 2 ball milling cans for use.

TENCAN Powder

TENCAN Powder-

DECO Instruments DECO-PBM-AD-12L Omnidirectional Planetary Ball mill

$ 4122.00 -

MODERNER XD-733 95 zircon bead grinding medium

Login -

DECO Instruments DECO-PBM-AD-60L All round planetary Ball mill for production

$ 12733.00 -

DECO Instruments DECO-PBM-AD-20L All round planetary Ball mill for production

$ 6992.00 -

DECO DECO-PBM-H-0.4L Laboratory horizontal planetary high energy Ball mill

$ 1537.00

Introduction

Tianxin's planetary ball mill is a required device for mixing, fine grinding, sample preparation, new product development and small batch production of high-tech materials. Our planetary ball mill has small size, full functions, high efficiency and low noise. It is a satisfactory equipment for scientific research institutions, universities and corporate laboratories to obtain research samples (four samples can be obtained simultaneously in each experiment). It is equipped with vacuum Ball milling tank can grind samples under vacuum.

Product application areas

Vertical semicircular planetary ball mill is widely used in geology, minerals, metallurgy, electronics, building materials, ceramics, chemical industry, light industry, medicine, environmental protection and other departments. It is suitable for electronic ceramics, structural ceramics, magnetic materials, lithium cobalt oxide, manganese acid Lithium, catalysts, phosphors, long afterglow luminescent powder, rare earth polishing powder, electronic glass powder, fuel cells, zinc oxide varistors, piezoelectric ceramics, nanomaterials, wafer ceramic capacitors, MLCC, thermistors (PTC, NTC ), ZnO varistors, dielectric ceramics, alumina ceramics, zircon oxide ceramics, phosphors, zinc oxide powders, cobalt oxide powders, Ni-Zn ferrites, Mn-Zn ferrites and other products.

Product Features

Effective, high-energy grinding to the particle size you need, the minimum particle size can reach 100 nanometers, the maximum grinding acceleration is 100G, and it takes at least 5 minutes to reach the grinding particle size; it can grind four parallel samples at the same time, improving the efficiency of multi-sample processing in your laboratory;

It can meet your needs for various grinding conditions: dry powder grinding, wet grinding, vacuum or atmosphere grinding, low temperature grinding, high temperature grinding, etc.;

It can be equipped with grinding jars and grinding media made of various materials to meet your needs of reducing impurities brought into the sample: stainless steel, alumina, alumina, agate, silicon carbide, nylon, polytetrafluoroethylene. Polyurethane, carbide, etc.

Up to 4 ball milling jars can be placed at the same time to grind 4 different types of samples, or 2 ball milling jars can be placed symmetrically;

Under the same conditions, when multiple ball milling jars grind the same sample at the same time, each ball milling jar will have the same grinding effect on the sample;

Under the same conditions, grinding the same sample in each batch will have the same effect;

The application covers a wide range of industries, a wide range of grinding sample types, and strong grinding flexibility;

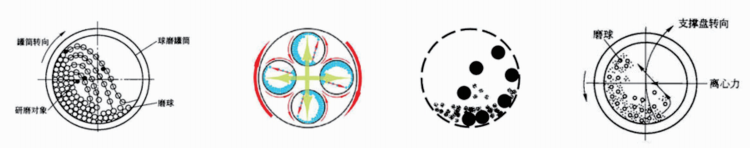

Principle

The main disk of the planetary ball mill is equipped with four ball milling jars. When the motor drives the main disk to rotate, the ball milling jars rotate with the main disk axis and rotate in planetary motion driven by the main disk planetary mechanism. The grinding balls in the tank rotate at high speed. The planets rub and collide with each other in the motion of the planets, and have the function of effectively grinding and mixing samples.

Application samples

Metal oxides, iron ore, iron powder, aluminum powder, magnesium powder, ceramic alumina, bone, kaolin limestone, gypsum, quartz, minerals, ores, carbon fiber, graphite, ink, clay minerals, fiber products, sewer sludge , catalysts, chemicals, alloys, soil, waste samples, wood, plant raw materials, cement slag, concrete, slag, tobacco, pearls, ginseng, dendrobium, tablets, pharmacies, licorice, coke, coal, glass, cellulose, Paper, chips, polymers, pigments...

Optional (need to be purchased separately)

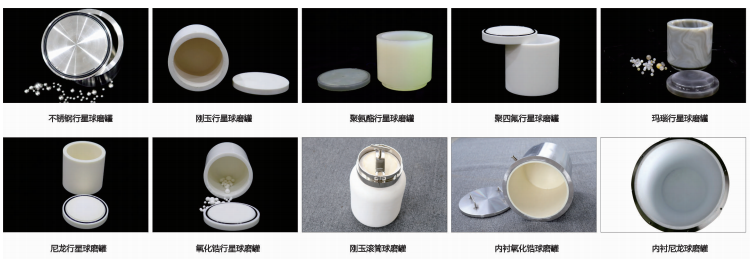

Ball mill tank

In the use of planetary ball mills, sample processing needs to be carried out in the ball milling carrier through the action of grinding media. Therefore, ball milling carriers and ball milling media are indispensable and main accessories of planetary ball mills. We provide ball mill tanks of various specifications, made of agate, corundum alumina, alumina, silicon nitride, silicon carbide, stainless steel, high wear-resistant steel, manganese steel, nylon, PU, ââcarbide, and other materials.

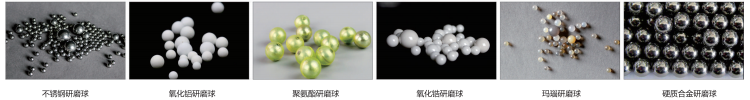

grinding ball

We can also provide various grinding balls: stainless steel balls, oxidized aluminum balls, alumina balls, PU balls, steel carbon balls, tungsten balls, agate balls, carbide balls, silicon nitride balls, high wear-resistant steel balls, manganese Steel balls, nylon balls, carbide, glass and other special metal materials.

TENCAN Powder XQM-0.4A Vertical Planetary Ball millSpecifications

| LIST | VALUE |

|---|---|

| Specifications | 0.4L |

| Can be equipped with ball mill tank specifications | 50~200ml |

| quantity | 4 pieces |

| Can be equipped with ball mill tank specifications | 50ml |

| Power | 220V/50Hz |

| Motor Power | 0.25kw |

| Total running time | 1~9999min |

| alternate running time | 1~999min |

| Adjustable Rotation speed - revolution | 45-435rpm |

| Adjustable Rotation speed - Rotation | 90-870rpm |

| noise | ≤58±5db |

| Motor Power | 0.25kw |

| Speed regulation mode | Frequency conversion speed regulation |

| Device Weight | 29kg |

| Equipment Volume | 500x300x340mm |

TENCAN Powder XQM-0.4A Vertical Planetary Ball mill Packing list

machine X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- 5 Ways to Improve Ball Mill Efficiency

- Factors Affecting the Grinding Efficiency of Ball Mill

- Principle and Application Analysis of Graphite Ball mill

XQM-0.4A

XQM-0.4A