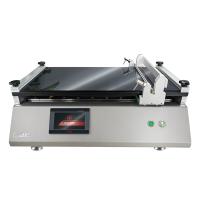

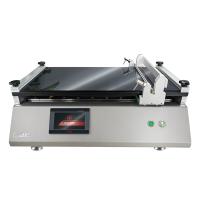

China TBJ-X4-DJ1 Vacuum chuck bar heating cloth testing machine Scraping Machine Size 400 * 500mm

Vacuum chuck + heating + bar three-in-one; Coating size 400 * 500mm; silent vibration-free motor, aluminum alloy baseplate, heating temperature up to 200 ° C; standard 1 imported high-precision bar; Customized Film Applicator.

-

HuiNuo TM1000/08 Bar Coater thick substrate Film Applicator 60 * 30cm

$ 1966.00 -

China TBJ-A3-DJ8 Automatic Film Applicator with automatic feeding system

$ 14280.00 -

China TBJ-X3-DJ5 drawdown Bar & blade heating Vacuum chuck Film Applicator with automatic feeding system

$ 7334.00 -

HuiNuo TM1300UVpro Automatic Film Applicator bar Spreader heating Vacuum chuck UV curing ECA 40 * 30cm

$ 4808.00 -

HuiNuo TM3300Pro/25 Multifunctional Film Applicator ECA 40cm * 30cm, drawdown Bar & blade Vacuum adsorption baseplate heating + upper cover heating (servo motor)

$ 7334.00

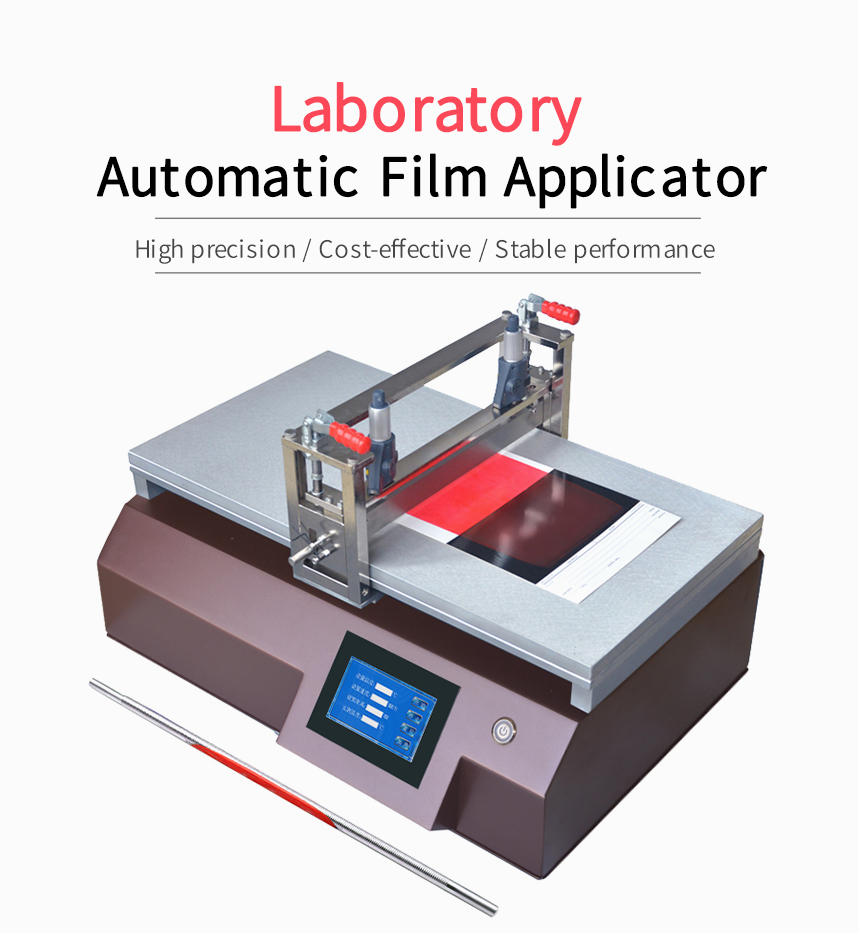

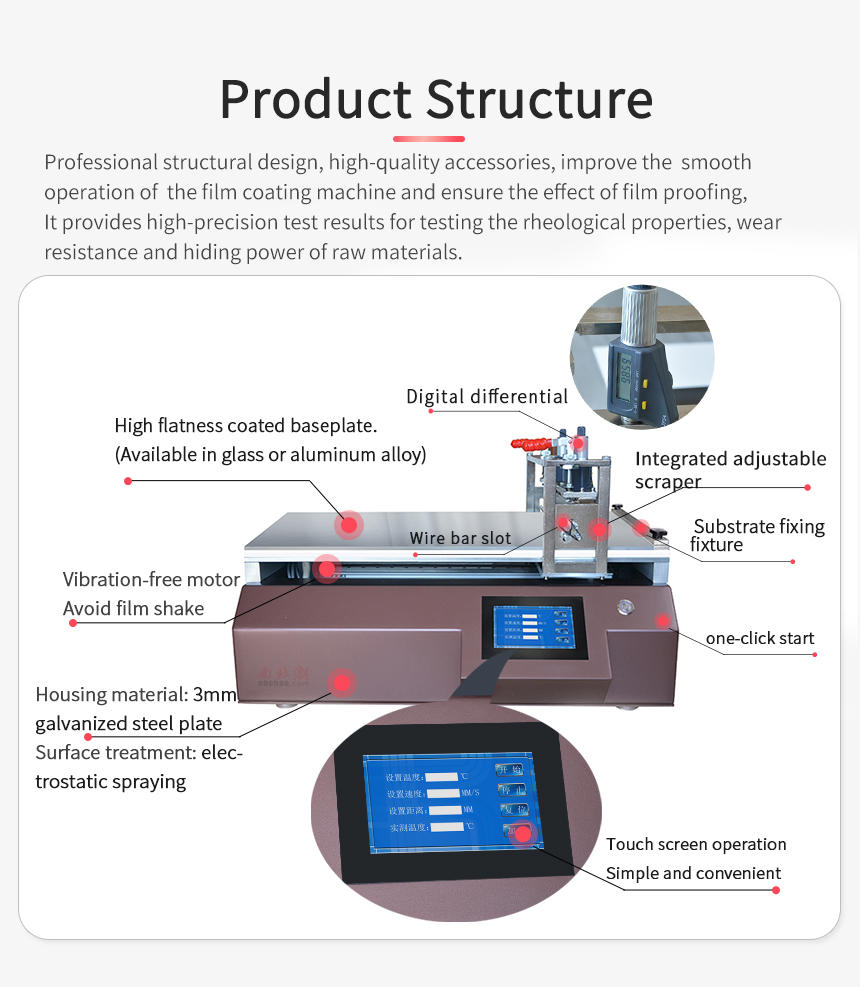

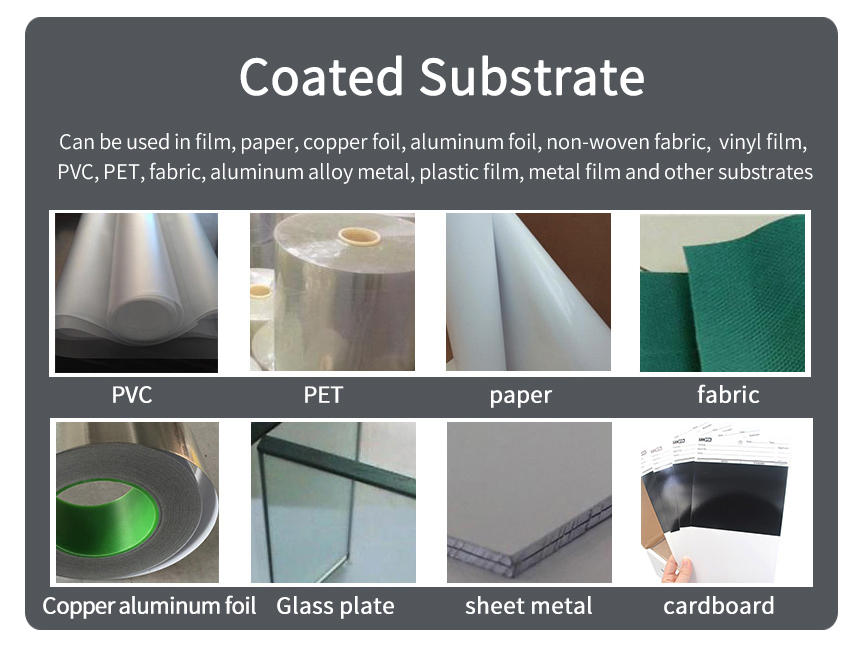

product description

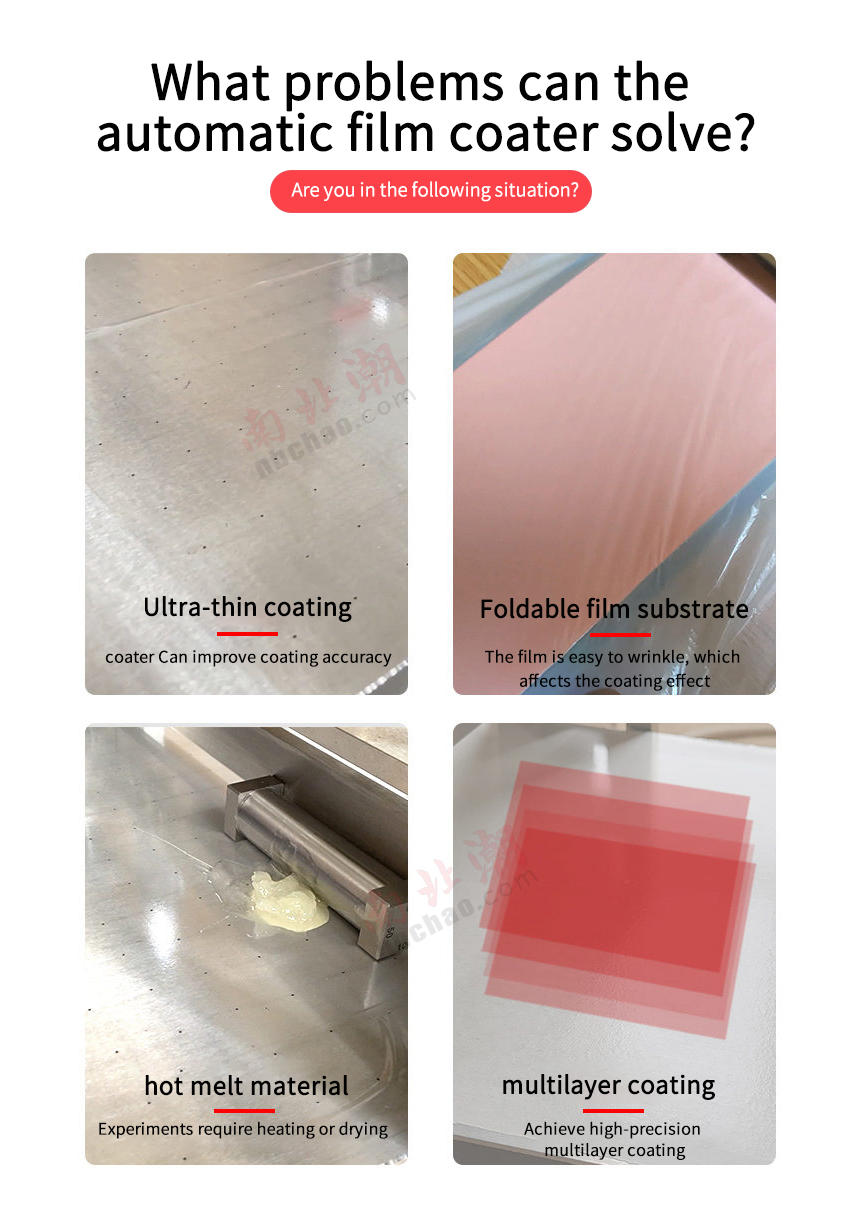

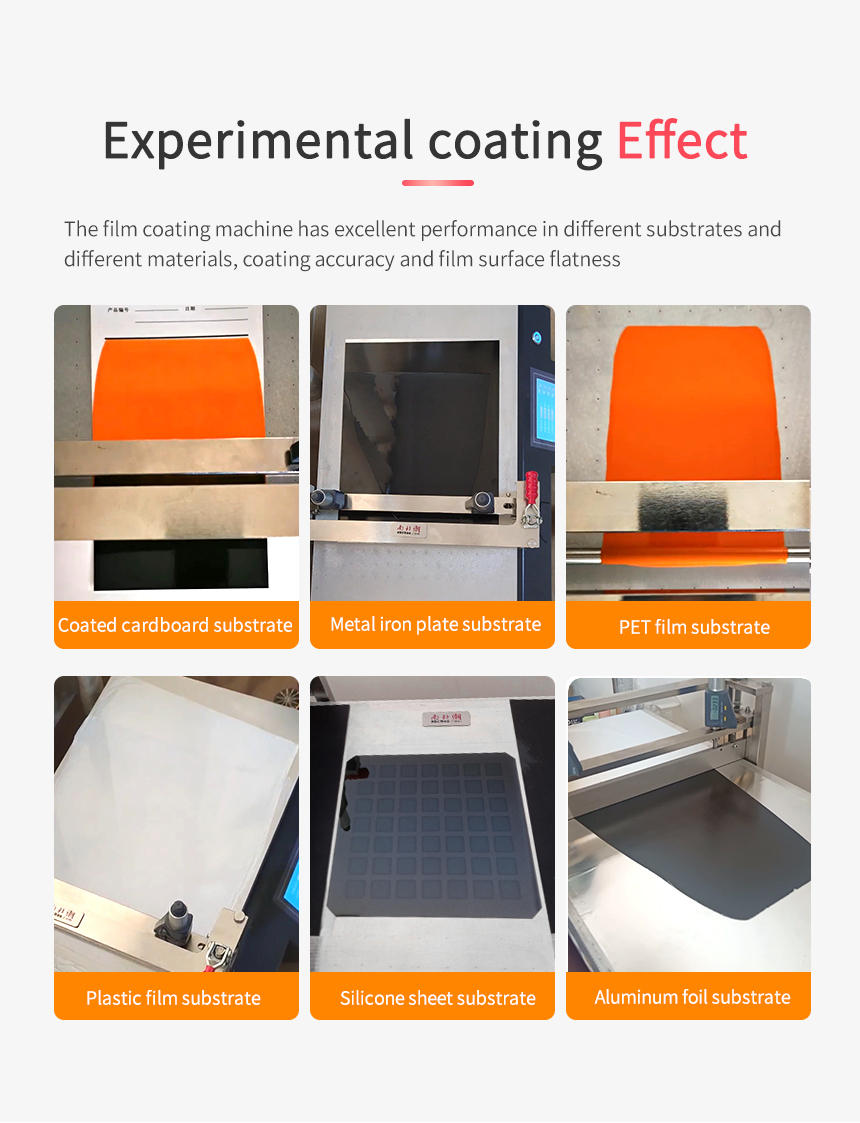

TBJ-X experimental small-scale coating testing machine all adopts imported accessories, and the price is excellent and low. It has been favored by many R&D institutions of multinational companies, many familiar universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure to ensure the effect of coating and glue, to ensure the uniformity and stability of coating and glue.

Since the main factors affecting the coating film are the coating speed and the pressure applied on the Film Applicator, etc., the coatings painted by hand are often inconsistent, especially the differences between different people are even greater, which is why This makes it difficult to compare test results between samples. The company's automatic Film Applicator is carefully designed to allow the operator to conveniently apply precise wet films on different substrates, which greatly improves the reproducibility of the coating film.

This automatic coating machine comes standard with one domestic (CN) wire rod and one imported wire rod with a precision up to 1μm .

Optional

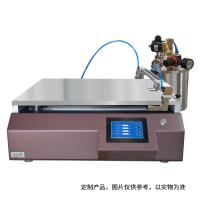

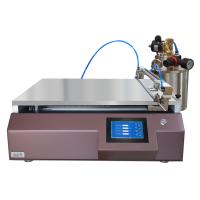

zy TBJ-X4-DJ1 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating method | bar |

| Mayer Rod Thickness Range | 1-571.5 μm (Spreader thickness according to bar model) |

| Mayer Rod Accuracy | ±0.001mm |

| Coating speed | 5-200Mm/s (< 5mm/s can be customized) |

| Coating size | 400 * 500Mm (Miscellaneous size can be customized) |

| Spreader distance control | Numbers can be set arbitrarily within the range of 1-500mm |

| Vacuum Area | 400 * 500Mm (can be customized) |

| vacuum aperture | Φ1.2mm |

| Vacuum hole spacing | 20*20mm |

| Substrate clamping method | Vacuum adsorption |

| Control mode | Touch screen control |

| Host Power Supply | 220V 50HZ |

| Dimension | 722*500*520mm |

| Weight | 65kg |

| speed control | Infinitely variable speed |

| Bottom plate material | aluminum alloy |

| Heating Temperature range | RT+~180℃ |

| Temperature Uniformity | ±3℃ |

| Heating mode | Baseplate heating |

| Power | 1500w |

| Vacuum pump size | 380*180*280mm |

| Optional Accessories | Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

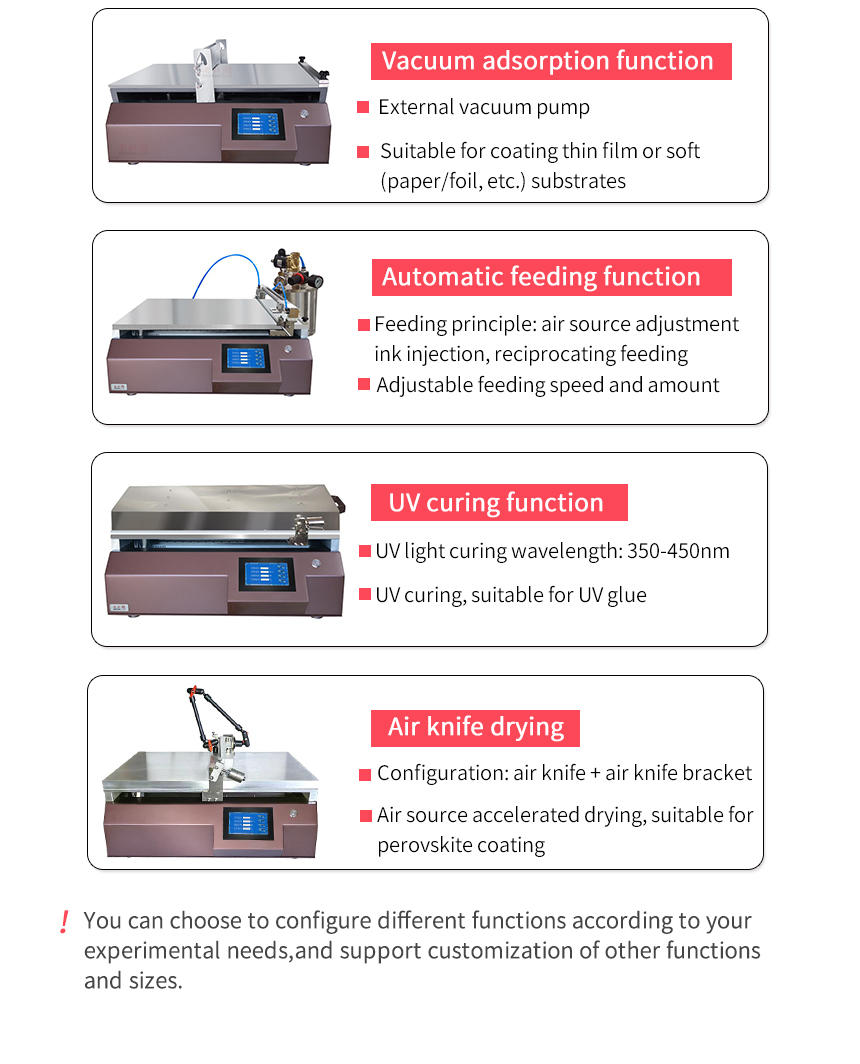

| customizable function | Automatic lame plating device, UV curing device, automatic inking system, air knife drying, remote control, upper infrared heating, double extrusion Spreader |

zy TBJ-X4-DJ1 Automatic Film Applicator Packing list

Film Applicator X1, External Vacuum Pump X1, Imported bar X1, China bar X1, Product Manual X1, Opacity Chart x1 box (250 sheets)

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Solving the fuel cell electrolysis membrane prepative challenge: Core Functions and Selection Considerations for Multifunctional Laboratory Film Applicators

- Application of Vacuum adsorption Spreader Technique in Preparative Fluorescence Film on Release Membrane

- Definition and use standard of film hiding power

- Technical Principle and Operation of Anode Film Applicator

- Experimental film coating machine case | Scrape coating slurry on release film

- Application technology and optimization of wire-rod Film Applicator on non-woven fabric

- Application of Film Applicator in Silver Nanowire film

- Fiberglass hot-melt adhesive coater technical analysis and operation guide

- The Film Applicator You Think Is Not What You Think

- Selection and Technical Analysis of Laboratory Film Applicators in Liquid Crystal Dimming Film

- ActiveGB/T 41515-2022

- ActiveGB/T 1727-2021

- ActiveHG/T 3355-2003

- ActiveHG/T 4914-2016

- ActiveGB/T 9756-2018

- ActiveASTM D823-2018

zy

zy TBJ-X4-DJ1

TBJ-X4-DJ1

TBJ-X4-DJ3

TBJ-X4-DJ3

TBJ-X4-DJ4

TBJ-X4-DJ4

TBJ-X4

TBJ-X4