RDS #9, Formed Mayer Rods Grooved Rods Applicator rod

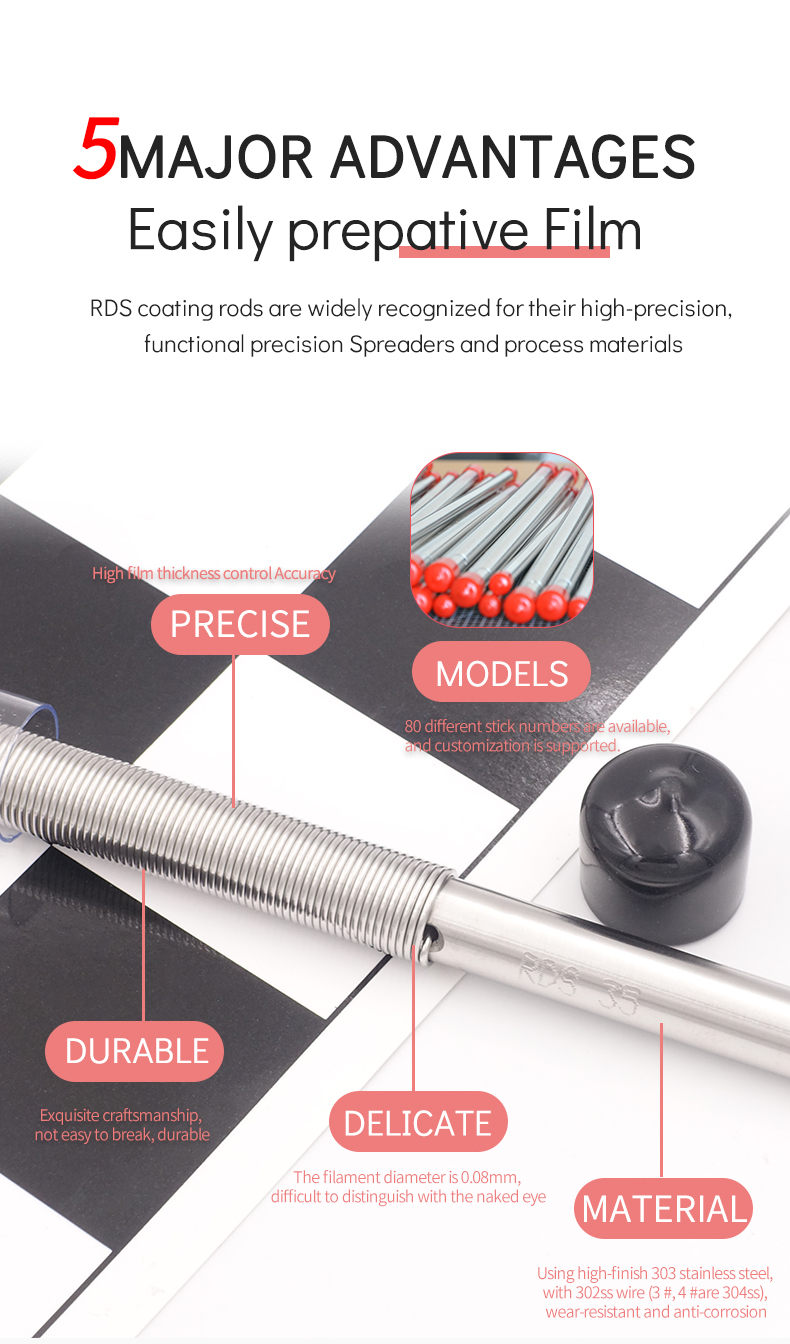

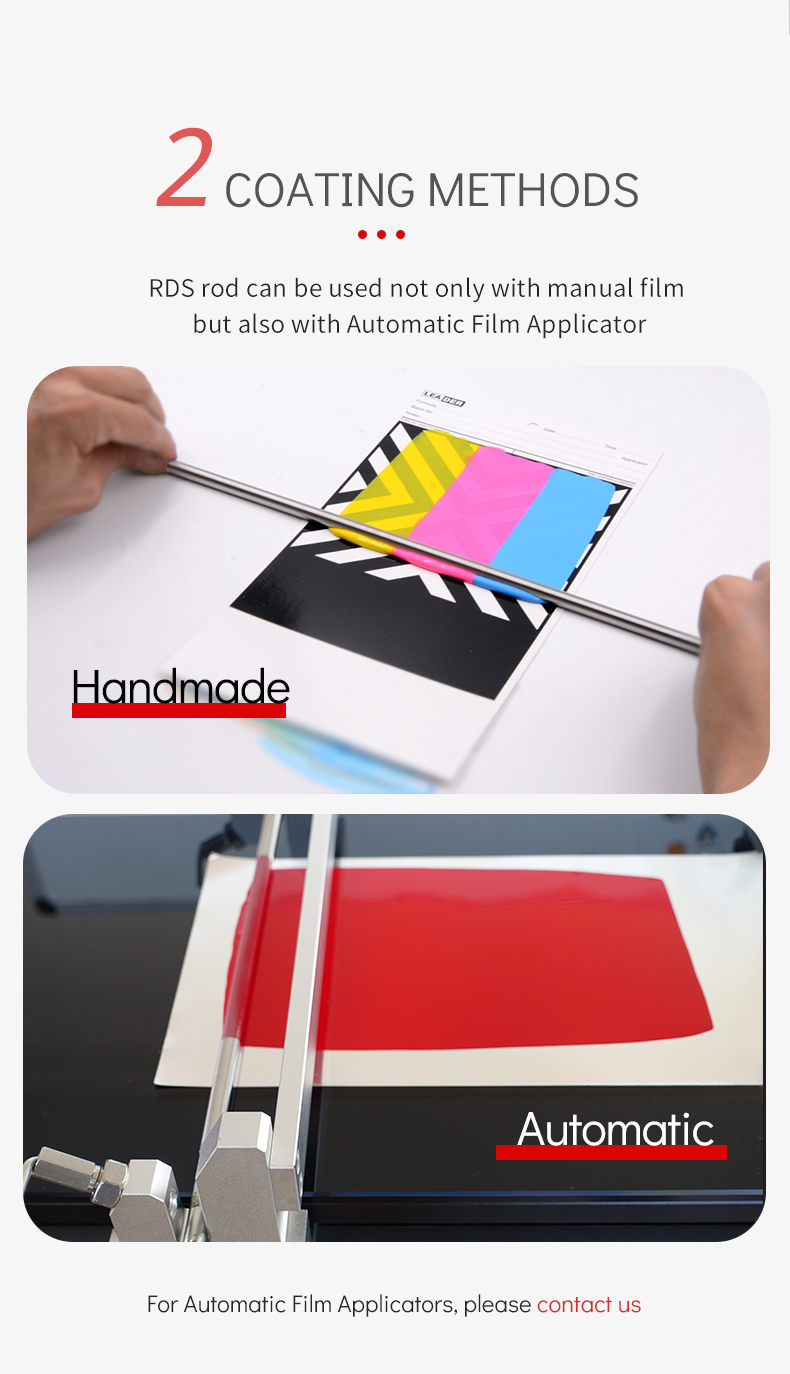

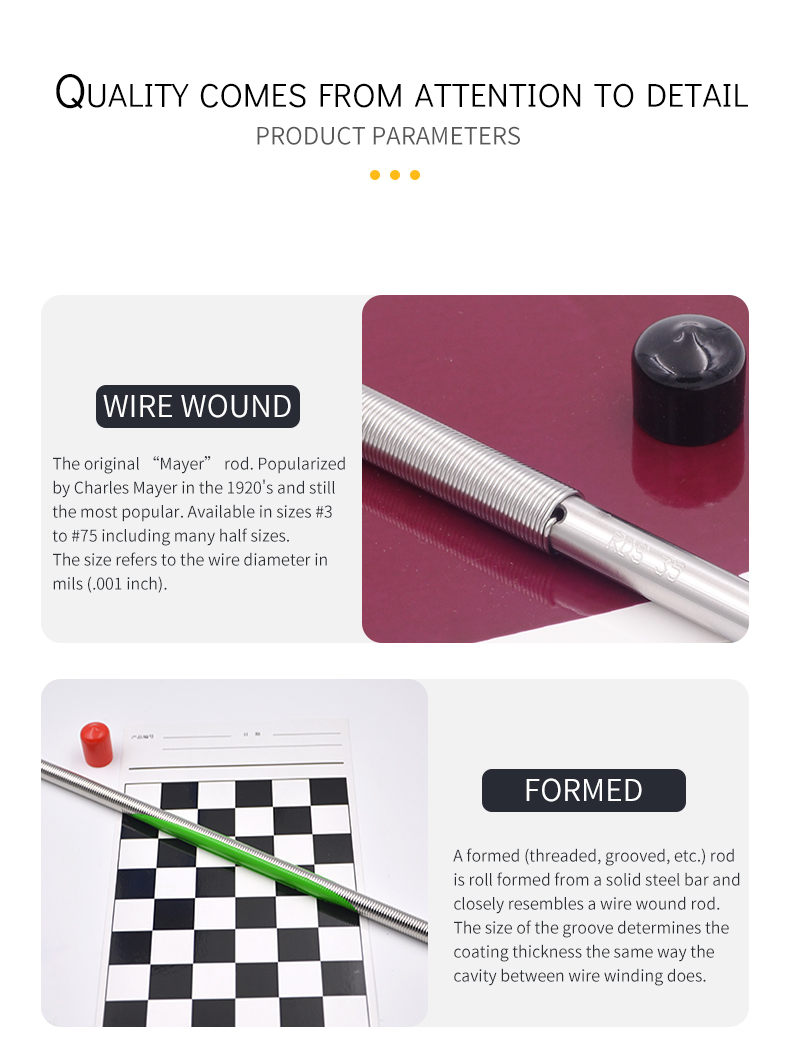

Formed process Mayer Rods, rod diameter 6.35mm, can be prepared 20.6 μm wet-film, easier to clean than wire-wound Applicator rod, continuous wire.

RDS

RDSProduct description

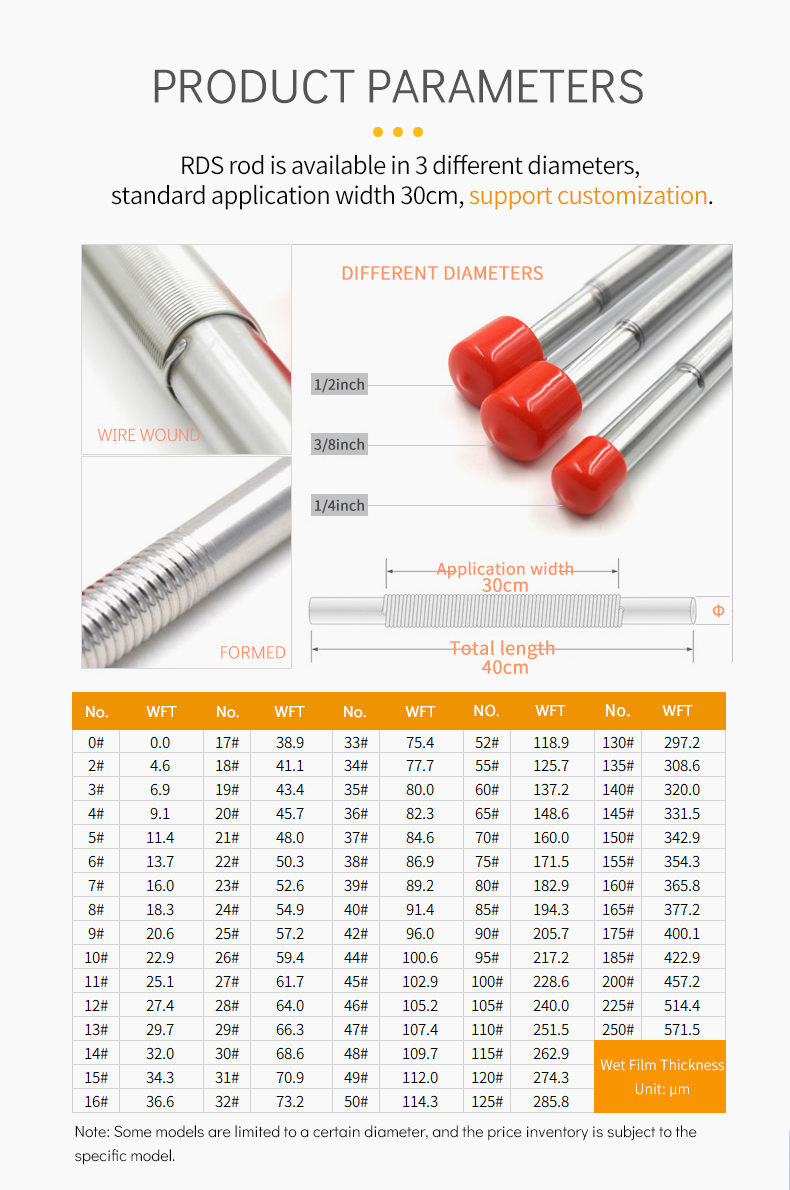

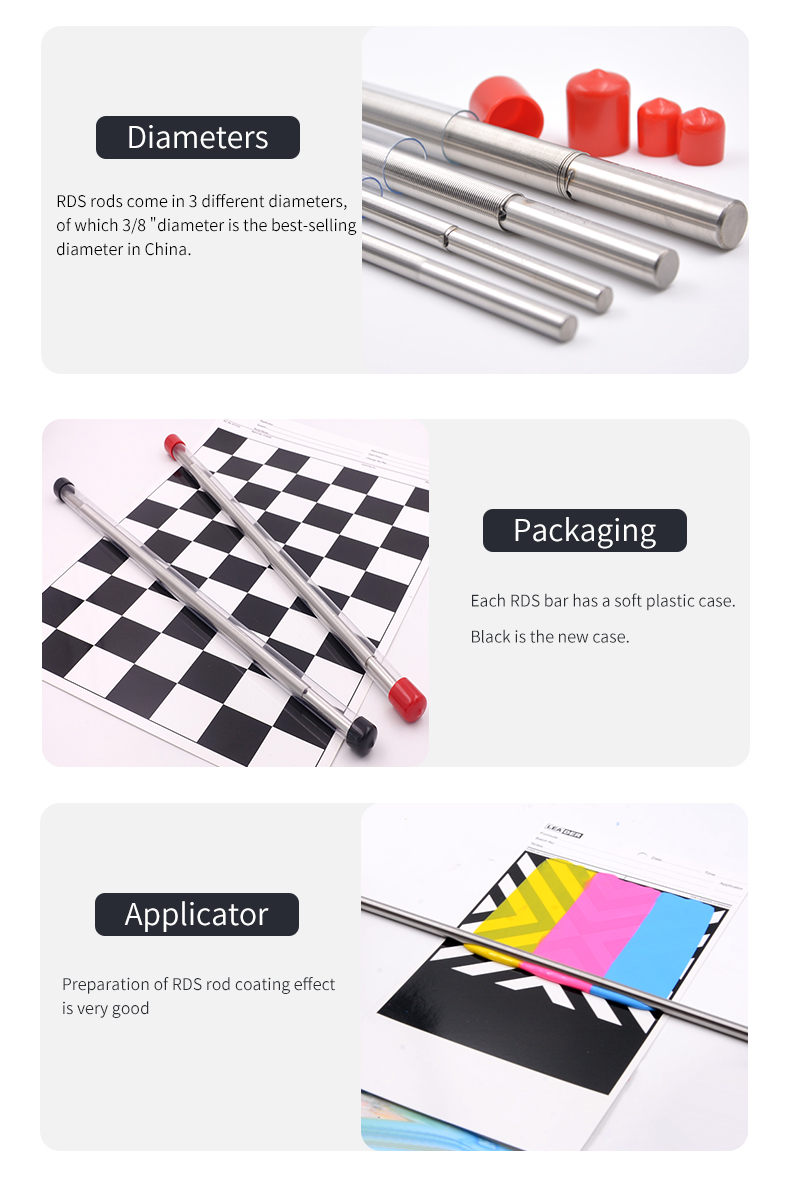

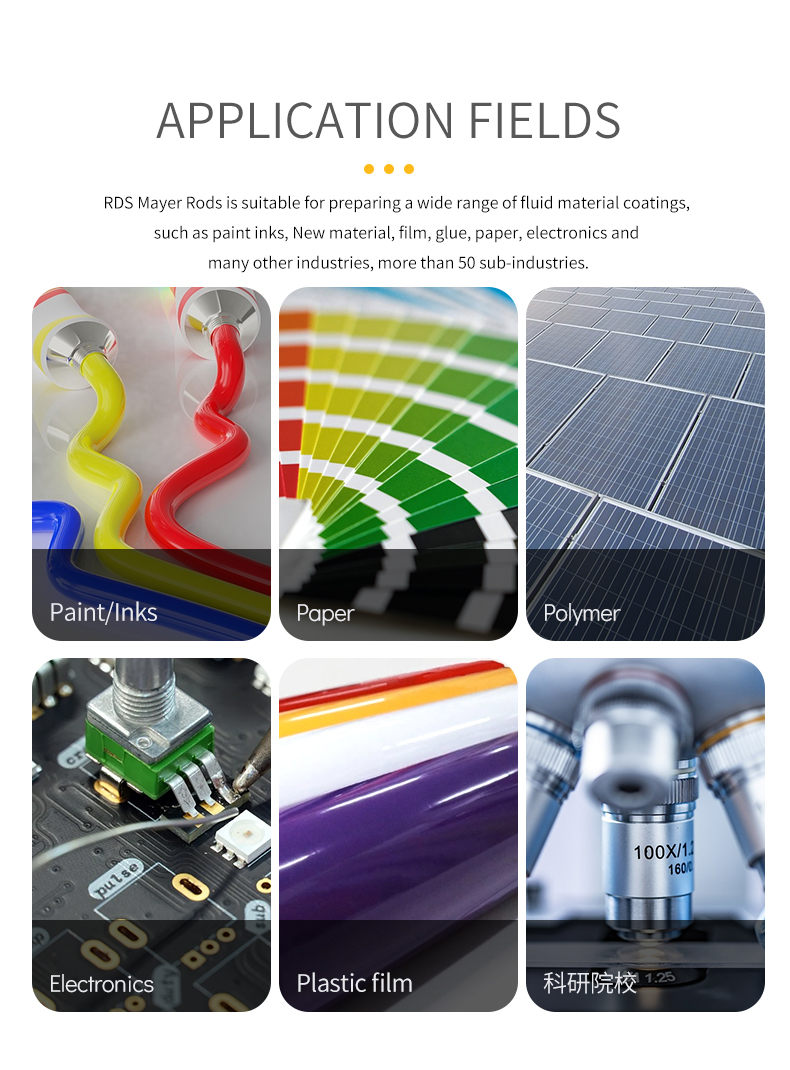

The RDS wire rod coater has 80 years of experience in the coating industry, and enjoys a great familiarity with domestic (CN) coating inks. The accuracy scale of its coating film is as high as 0.1 micron. For users who pursue high-precision coating film thickness It is quite satisfactory. RDS#9 wire Bar Coater can prepare wet film thickness of 20.6 microns, divided into three diameters of 6.35mm, 9.5mm, and 12.7mm, mainly to adapt to different user habits, in terms of film thickness and precision. it's the same.

RDS No. 9 Forming Rod Coater is a "non-" wire-wound rod with a diameter of 1/4 inch, which can prepare a wet film of 20.6 μm. Compared with the wire-wound film coating rod, it is easier to clean and has no wire.

RDS 9# 1/4“ Applicator rod 1/4 "Specifications

| LIST | VALUE |

|---|---|

| Production process | formed |

| WFT | 20.6μm |

| diameter | 6.35mm |

| Total length | 400mm |

| application width | 300mm |

| Grip Width | 50+50mm |

| material | stainless steel |

RDS 9# 1/4“ Applicator rod 1/4 " Packing list

Stainless Steel Rod X1 Transparent Encasement Hose X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- Application of Mayer Rods in composite coating prepative

- Advantages of Bar Spreader in corrosion coating prepative

- ActiveGB/T 22374-2018

- ActiveGB/T 1727-2021

- ActiveGB/T 7044-2022

- ActiveGB/T 23997-2009

- ActiveHG/T 20720-2020

- ActiveHG/T 5370-2018

- ActiveHG/T 3951-2007

- ActiveHG/T 3948-2007

- AbolishGB/T 13217.1-2009

- ActiveASTM D823-2018

- AbolishGB/T 9270-1988

9# 1/4“

9# 1/4“

9# 3/8"

9# 3/8"

9# 3/8"

9# 3/8"