IWAVE WH-81 Coating Thickness Gauge magnetic thickness measurement method 0~1250μm

Measurement range 0~1250μm, error range +/- 3%, can quickly and accurately detect the thickness of coatings.

IWAVE

IWAVE-

PUSHEN PIG Multipurpose Dry-Film Detector

$ 640.00 -

German EPK MikroTest Ni50 McCourt Eletroplating Nickel Thickness Gauge, Thickness Measurement: 0~50μm

$ 2047.00 -

Netherlands TQC Powder TAG LD5850 Powder coating thickness analyzer wet-film/Dry-Film thickness measurement

Login -

Germany EPK MiniTest 735 FN1.5 dual-use Film Thickness Gauge thickness 0~1500μm/0~700μm

$ 2838.00 -

YIBAI CTG-600Z Coating Thickness Gauge can switch to display galvanized gram weight and thickness

$ 301.00

Introduction

IWave coating Thickness Gauge WH-81 has two models: single iron base and iron and aluminum double base, which respectively adopts magnetic thickness measurement method and magnetic eddy current dual-purpose thickness measurement method, which can quickly and accurately detect the thickness of the coating without destructiveness, and the applicable thickness measurement range is 0~1250 microns. WH-81 coating Thickness Gauge is an all-in-one probe Thickness Gauge, small size, very easy to carry, can be used in the laboratory or engineering site, in the manufacturing industry, metal processing industry, automotive industry, chemical industry, commodity inspection and other fields are widely used, such as spraying, painting, oxide film, electroplating, etc. WH-81 (single iron-based/iron-aluminum double-base) coating Thickness Gauge conforms to GB/T 4956-1985, GB/T 4957-1985, JB/T 8393=1996, JJG 889-95, JJG 818-93 and other standards.

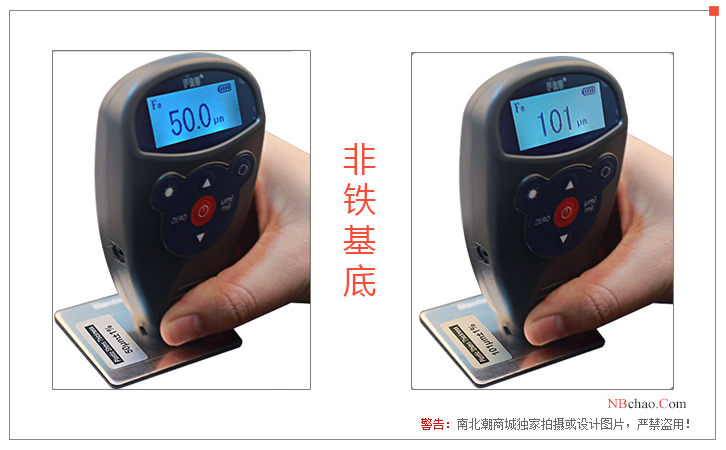

Actual picture of the product

Features

1. The WH-81 coating Thickness Gauge adopts two thickness measurement methods, magnetic and eddy current, which can measure the thickness of the non-magnetic covering layer on the magnetic metal collective and the thickness of the non-conductive covering layer on the non-magnetic metal matrix.

2. The coating Thickness Gauge can be calibrated by two methods: single-point calibration and two-point calibrationWH-81 Coating Thickness GaugeCalibration is carried out, and the systematic error of the measuring head can be corrected by the basic calibration method to ensure that the instrument is in the measurement processWH-81 Coating Thickness Gaugeaccuracy;

3、It can quickly and automatically identify ferrous and non-ferrous substrates;

4、WH-81 Coating Thickness GaugeIt has the function of power supply under-Voltage indication;

5、There is a beep prompt during the operation;

6、There are two shutdown modes: manual shutdown mode and automatic shutdown mode;

7、There is a negative number display function, guaranteedWH-81 Coating Thickness Gaugecalibration accuracy at the zero site;

8、There is a function to display the average, maximum, and minimum values.

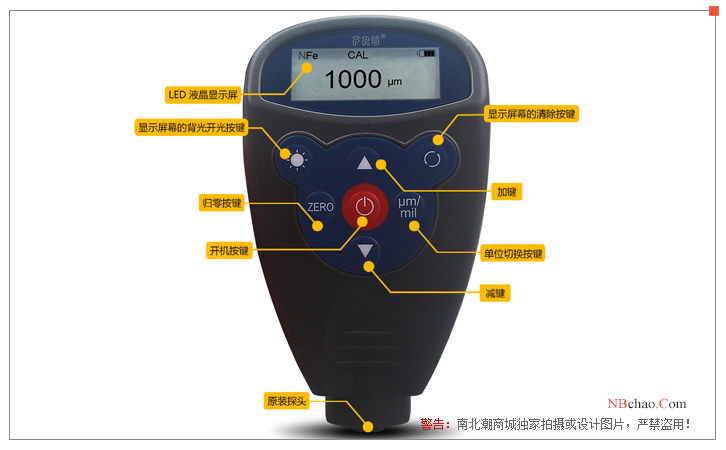

buttons and display instructions

1) The operation panel of the WH-81 coating Thickness Gauge is a bear shape, from left to right, from top to bottom the buttons are as follows:

● "Sun Symbol": The backlit button that displays the screen ● Ring:Displays the clear button for the screen

● Ring:Displays the clear button for the screen

● "Power Symbol": Power on button

● "ZERO": Reset button

● "μm/mil": unit switch button

● "▲" plus key, "▼"Subtract the key

2) Description of display parameters

Basic Edition: Enhanced Edition

●mm(mil) unit of measurement

●CAL calibration tips

●Fe indicates the measurement status of the magnetic substrate

NFe indicates the non-magnetic substrate measurement state

●1000 measurement thickness display area

●T010 represents the 10th measurement, AVG represents the average value of 10 measurements, MAX represents the maximum value in 10 measurements, MIN represents the minimum value in 10 measurements, and the average measurement can be up to 999 times;

● Power supply underVoltage prompt

How to use:

1) Power on

After pressing the "ON" button, the WH-81 coating Thickness Gauge emits a beep, which will automatically restore the parameter settings before the last shutdown and display 0.0μm, indicating that the WH-81 coating Thickness Gauge has entered the pending state. Now it's time to measure the workpiece to be measured. If the WH-81 coating gauge is not used for a period of time, it will automatically shut down.

2) Shut down

In the absence of any operation, the WH-81 Coating Thickness Gauge automatically shuts down after approximately 3 minutes. Press the "ON" button once to power off immediately.

3) Unit Conversion (Metric to Imperial Conversion)

In the state to be measured, the WH-81 coating Thickness Gauge is measured in μm/mil convertible.

4) Measurement

a) Prepare the artifact to be tested

b) Determine if calibration of the WH-81 coating Thickness Gauge is required and, if so, select the appropriate calibration method

c) Quickly put the measuring head perpendicular to the test surface and gently press the measuring head positioning sleeve, a beep, the screen displays the measured value, and the WH-81 coating Thickness Gauge will automatically sense the substrate to be measured: when it is a magnetic substrate, the WH-81 coating Thickness Gauge will show Fe, and when it is a non-magnetic metal, the WH-81 coating Thickness Gauge will show NFe. (Iron-aluminum bi-base type can be automatically recognized, single-iron-based type can only measure magnetic substrates)

Note: Keep the WH-81 Coating Thickness Gauge vertical while measuring. When the measuring head is lifted, the next coating measurement can be taken;

Troubleshooting methods

1) Replace the battery

If the WH-81 coating Thickness Gauge is not used for more than 5 consecutive days, the battery should be removed. When the WH-81 coating Thickness Gauge has a low Voltage prompt, the battery should be replaced, and the polarity should be paid attention to when replacing the battery.

2) Factory reset

In the power-on state, press the button, ▲, ▲, ▼, ▼ in order within 2 seconds, and the screen will display an English dialogue asking whether to confirm the factory reset, to restore the factory settings, select "<Yes>" and press μm/mil to confirm.

3) Calibration correction of the measuring head

If there is a large error (such as: improper calibration or operation error, etc.), a six-point correction calibration can be made to calibrate the WH-81 coating Thickness Gauge.

IWAVE WH81 Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~1250μm |

| margin of error | ±3% |

| Minimum measurement surface | 10*10mm |

| Minimum radius of curvature | Convex 5mm; Concave 5mm |

| thinnest substrate | 0.4mm |

| probe | F integrated probe |

| statistical function | MAX Maximum, MIN Minimum, Average |

| icon function | without |

| Power Supply | 2 * AA battery |

| Standards | GB/T 4956-1985、GB/T 4957-1985、JB/T 8393-1996、JJG 889-95、JJG 818-93 |

| Calibrated Certificate | without |

| system language | Chinese |

| Display screen | LCD screen |

| supporting software | without |

| Machine Weight | 115G (including battery) |

| Machine size | 110*65*30mm |

| Power Supply | Two AA batteries |

| Operating temperature | 0~40℃ |

| Relative Humidity | ≤85%RH |

IWAVE WH81 Coating Thickness Gauge Packing list

Host x1, iron substrate x1, calibration shim x1, AA battery x2, certificate x1, manual x1, Encasement box x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveGB/T 44757-2024

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveJJG 818-2018

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveSY/T 0315-2013

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

WH82

WH82