DIANYANG TA-60 thermal imagery analyzer resolution 640 * 480/550 ℃

640 * 480 resolution, 56 ° X42 ° field of view, NETD is 50mK@25 ℃, temperature measurement up to 550 ℃, flexible configuration of data sampling Frequency, maximum temperature, minimum temperature, average temperature three temperature measurement methods, can store temperature data, support photography and video.

DianYang

DianYang-

DIANYANG CA-30 CA Series Research Thermal Analyzer Infrared thermal imagery thermometer, wide temperature measurement range -20 ℃~ 550 ℃

$ 5597.00 -

Dianyang DP-21 thermal imagery handheld, resolution 220x160

$ 435.00 -

Dianyang DP-22 thermal imagery handheld, resolution 320x240

$ 700.00 -

DIANYANG CA-20D infrared thermal imagery analyzer, circuit board thermal fault detection

$ 1414.00 -

ST9450A + infrared thermal imagery instrument

$ 419.00

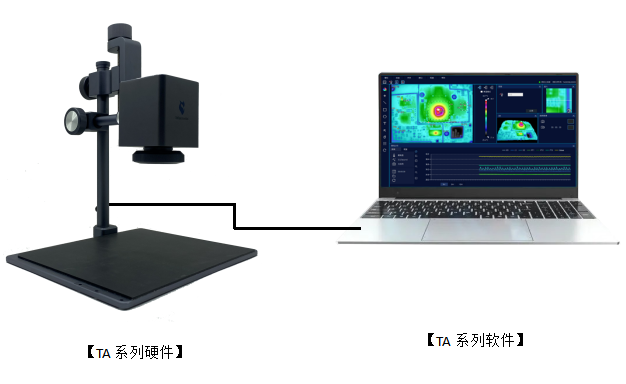

Introduction

TA series thermal analyzer uses the principle of infrared detection imaging to detect and measure the data of object temperature change over time, and can carry out unlimited data storage and reliability analysis of measurement results. TA series thermal analyzer is suitable for circuit design, component testing, heat dissipation and thermal conductive material testing, electronic smoke and other thermal field testing.

Features

1. Detection temperature:

A variety of temperature detection drawing tools: point, line, rectangle, polygon, nine-square diagram (proportional segmentation map);

16 special color palettes for a wide range of different applications;

Detailed investigation in a rectangular frame, suitable for observing the local temperature change of the thermal field;

Multiple temperature width detection methods: dynamic temperature width, highlight high temperature area, isotherm;

A variety of temperature data display: high temperature, low temperature, average temperature;

A variety of temperature change curves are displayed: global temperature, 40 point temperature measurement, 20 regional temperature measurement;

2. Storage of temperature data:

Record temperature data and information for unlimited time and save it in CSV format;

The temperature sampling frequency can be flexibly configured, 50ms, 100ms, 200ms...... 1s;

When the temperature threshold is exceeded, it can be automatically photographed and saved, which is suitable for offline analysis;

Manual photo and video recording is supported.

3. Analyze infrared thermal imaging data:

Online temperature analysis, real-time analysis of the temperature change of each point on the line;

The measured temperature data can be displayed in real time with curves, and multi-time display is supported: 1 minute, 5 minutes and 10 minutes;

CSV format data analysis, suitable for offline analysis;

Offline analysis of infrared thermal images;

Multi-dimensional comprehensive analysis of infrared thermal image, time and temperature changes;

Isotherm analyses of temperature thermal field;

Application examples

1. Application of TA thermal analyzer in PCBA

Every hot spot on the circuit board has the potential to affect the performance of other devices or products, and thermal analyzers can solve the problem of temperature and temperature change process detection for users such as R&D and production.

Multi-zone measurement, suitable for module testing in each area of PCBA;

Operating temperature range: -10°C~+55°C, measurement range: -10°C~550°C, suitable for circuit board measurement in multiple scenarios;

High-temperature high-brightness and wide temperature detection, quickly capture the high temperature of the circuit board;

High temperature alarm, photo, video and other functions are used to analyze the working process of the circuit board;

2. Thermal analysis of heat dissipation and thermal conductive materials

In the use and research and development of raw materials, Dianyang TA series thermal analyzer can detect and analyze the temperature of thermal conductivity, heat dissipation and uniformity of materials.

Multi-color slab function, each color swatch, the focus on color and temperature color difference are different, suitable for the analysis of all kinds of different materials;

Isotherms, which can fix temperature bars and colors according to a variety of temperature ranges, are an important tool for users when performing thermal analysis of materials;

Massive actual temperature measurement data from 40 points and 20 areas to detect the heating uniformity of materials;

On-line distribution function, real-time detection of heat conductivity characteristics of materials;

50mk temperature measurement accuracy, detect the thermal conductivity change of thermal conductive materials;

3. Development and design of electronic smog gas

In the quality of e-cigarette products, the temperature control ability is a very important index, which determines the efficiency of the atomizer on the atomization of e-cigarette oil and has a great impact on the taste.

Customize the simulated suction force, duration and frequency of the suction pump, analyze the temperature change trend on the curve, and assist in the selection of product design schemes;

Simple assembly method, batch detection of the working tolerance range of resistance heating wire;

Automatically draw an equal proportional segmentation map, which can detect the temperature of multiple products at the same time;

Flexible data sampling frequency, complete observation of heating and cooling process, 50ms, 100ms, 200ms...... 1s;

The 3D mode detects instantaneous or small changes in the product, complementing the 2D function;

The uniformity measurement function of the heating surface allows you to visually see the heating uniformity during atomization heating.

Scope of application of the software

Positioning, detection and maintenance of PCBA leakage, short circuit and open circuit position;

Comparative evaluation of mobile phones or other smart devices;

Auxiliary analysis of electronic equipment performance;

temperature control of electronic cigarette smokers;

Temperature conduction analysis of thermal conductivity and heat dissipation materials;

Homogeneity analysis of materials;

Heating experiment, thermal simulation, heating rationality verification in circuit design;

Product heat dissipation capacity testing;

Evaluation and comparison of equipment heating conditions

System Requirements:

Computer operating system: Win10 and above operating system;

Minimum computer configuration: CPU i5 and above, minimum memory 4G, recommended 8G or above; If you need to test a large amount of data, save applications and 3D temperature, it is recommended to use i7 CPU (or equivalent AMD CPU) with more than 8G memory;

The computer needs to install the Microsoft Visual C++ Redistributable (2005-2019) patch, otherwise the software will not work;

DianYang TA-60 Thermal imagery analyzerSpecifications

| LIST | VALUE |

|---|---|

| IR resolution | 640*512 |

| Light spectrum range | 8~14μm |

| NETD | <50mK@25℃ |

| Field of view | 45.75°×37.3° |

| frame rate | 25Hz |

| Focus method | manual focusing |

| Operating temperature | -10~55℃ |

| Temperature Measurement Range | -10~550℃ |

| Temperature measurement method | Maximum temperature, minimum temperature, average temperature |

| Accuracy | ±2℃/±2%/±3% |

| Measurement distance | 40~2000mm |

| temperature correction | Manual/Automatic |

| emissivity | 0.1~ 1.0 adjustable |

| Frequency of data sampling | 15 sampling times per second |

| image file | Full temperature JPG thermogram (Radiometric-JPG) |

| video file | MP4 |

| Veneer size | 220Mm x 172mm, Height 241mm |

| Double board size | 346Mm x 220mm, height 341mm with splicing plate and extension rod size |

| Data collection accessories | Not included in the standard configuration |

| Heating station | Standard 2 resistance heating wires can be filled with oil test holes, which can be customized; custom adjust the simulated mouth suction force, duration and times of the suction pump |

| data collection | Record temperature data without time limit, including temperature change data, data corresponding to resistance heating wire and resistance value, data corresponding to simulated Power Supply time and temperature, and calculation of heating uniformity |

DianYang TA-60 Thermal imagery analyzer Packing list

Resolution 640 * 480 Thermal Analyzer lens X1, anti-static support frame X1, thermal analysis software X1, table X1, hexagonal screws X4, hexagonal wrench X1, simple manual X1, certificate X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- How do thermal imaging cameras store photos?

- How to use Infrared thermal imager for roof moisture inspection?

- Infrared thermal imager - Where is it mainly used?

- Application of FLIR Thermal Imager in Ship Industry

- Types of non-destructive testing

- Work and Application of Infrared thermal imager Sensors

- Key indicators of infrared thermal imagery

- What is Infrared thermal imager? How does it work?

- Infrared thermal imager Why higher temperatures aren't always better

- Emissivity: Learn how it affects your Infrared thermal imager imagery

TA-60

TA-60