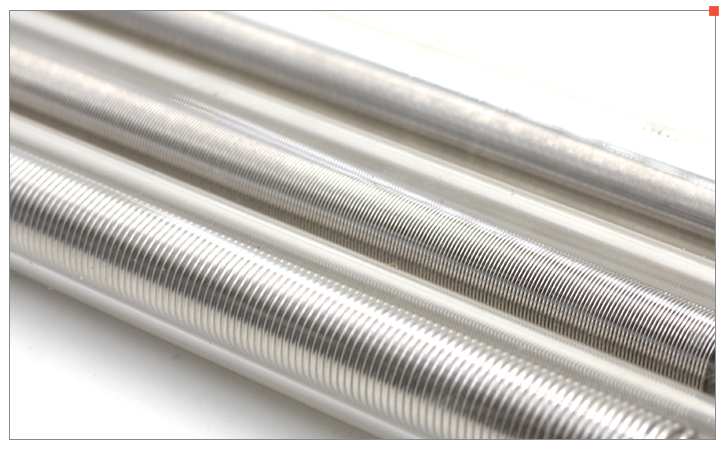

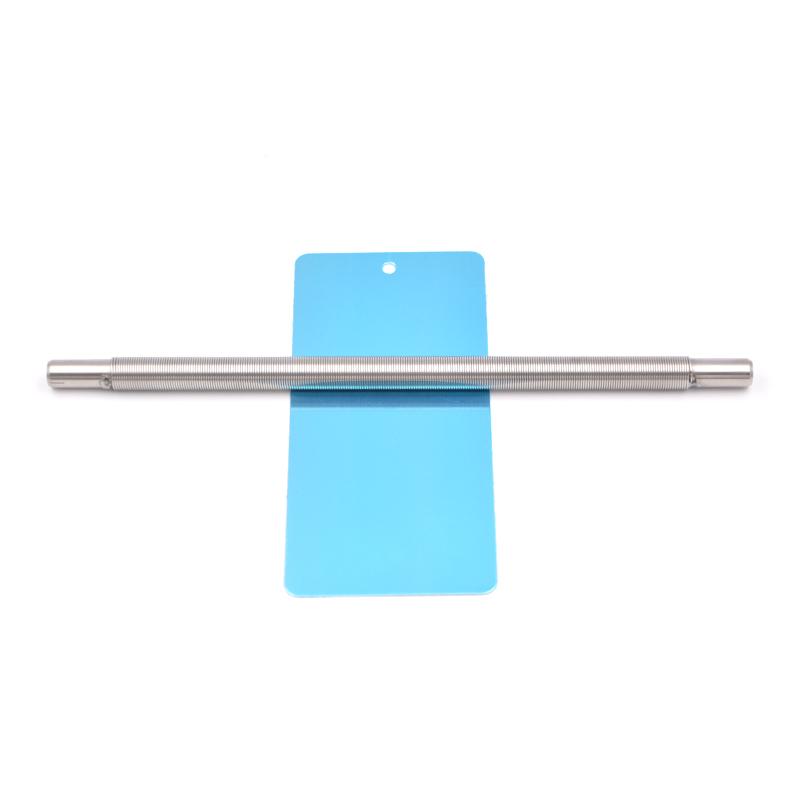

Pushen XB-I 150μm wire rod, length 240mm

Wire-wound, wet film thickness 150μm, Total length 240mm, application width 200mm, hand width 20 + 20mm, material stainless steel.

Pushen

PushenIntroduction

Pushen XB-I 150μm wire rod is a laboratory wire rod for the preparation of wet film, using the groove formed by winding the stainless steel wire on its surface to control the thickness of the wet film, 150 micron wet film thickness can be prepared,The Total length is 240mm, and the effective coating width is 200mm,It is widely used in plastics, inks, coatings, paints, plastics and other industries, and stainless steel has a longer service life.

Parameters

| Model | Coating thickness (μm) | Coating width(mm) | Overall length (mm) |

| XB-I 150μm | 150 | 200 | 240 |

| XB-II 150μm | 150 | 300 | 400 |

Features

Ideal for testing very thin coatings, such as can coatings and paper coatings. Wet film calculations

The thickness of the wet film that can be applied is engraved on the end of the XB wire rod.

It works best on soft materials such as paper, cardboard, foil, leather, test cardboard, textiles, etc.

The rod and winding are made of high-grade wear-resistant stainless steel.

How to select the coating rod

Wet film thickness = coating amount per square meter g/(density × solids content %)

*Note: The above formula is for reference only, the actual wet film thickness is also affected by various factors such as product elongation, viscosity, coating rod type, etc.

The laboratory wire rod is wound on the surface of the stainless steel wire to form a groove, which can prepare wet film with different wet film thicknesses, which is suitable for the preparation of ink film

Applications

For products such as paints, varnishes, inks, glues, etc., the reliability of many tests is directly related to the quality of the samples provided.

Steel wires of different diameters are wound on stainless steel rods of a certain length, and the gaps between the steel wires are used to prepare coating films of different thicknesses.

A very important \ basis for any kind of testing performed on such coatings, whether to illustrate their cosmetic or physical properties (e.g., color, gloss, opacity, drying time, etc.) is that the sample needs to be homogeneous, comparable, and precisely controlled in thickness.

Actual picture of the product

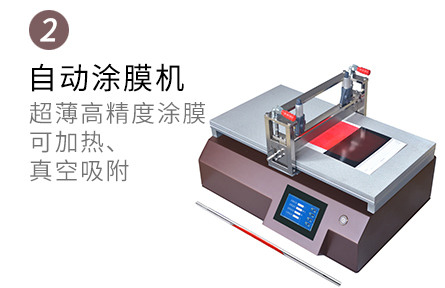

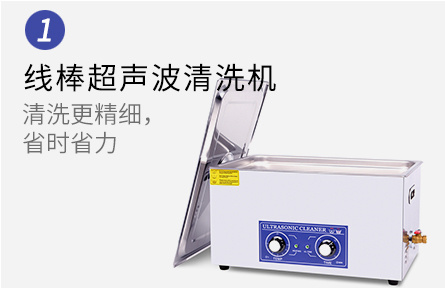

Optional

| |

|  |

Note: Click on the accessory image to view the product details.

Pushen XB-I 150um Mayer RodSpecifications

| LIST | VALUE |

|---|---|

| Production process | Wire-wound |

| WFT | 150μm |

| Total length | 240mm |

| Application width | 200mm |

| grip width | 20+20mm |

| material | stainless steel |

Pushen XB-I 150um Mayer Rod Packing list

Main Rod X1, External Encasement Pipe X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveGB/T 1727-2021

- ActiveHG/T 20720-2020

- ActiveHG/T 5370-2018

- ActiveHG/T 5065-2016

- ActiveHG/T 3951-2007

- ActiveHG/T 3948-2007

- ActiveASTM D4147-2023

- AbolishGB/T 13217.1-2009

- AbolishGB/T 13217.7-2009

- AbolishGB/T 13217.1-2009

- ActiveASTM D4147-2023

- ActiveASTM D823-2018

- ActiveJB/T 7663.2-2007

XB-I 150um

XB-I 150um