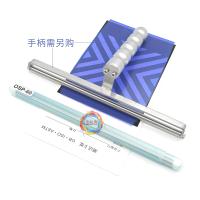

RDS 130G #3/8 "Glue Mayer Rods Gap Spreader 297.2μm

Interstitial wire-wound, Film thickness 297.2μm, diameter 9.52mm, suitable for high viscosity fluid scraping.

RDS

RDS-

RDS 50 #1/2 "Mayer Rods film thickness 114.3μm Wire diameter 1.27mm

$ 182.00 -

Japan OSP-06/250 paint stick WFT 6μm length 250mm

$ 154.00 -

RDS 26 #1/4 "printing roll Wire-wound drawdown Bar film thickness 59.4μm rod diameter 6.35mm

$ 157.00 -

RDS 20 #1/4 "wire-wound Applicator rod film thickness 45.7μm Wire diameter 0.51mm

$ 157.00 -

RDS 35 #3/8 "Molded Drawdown Rod 80.0μm Scraping Tester

$ 163.00

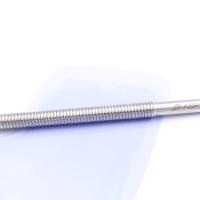

Preparation principle

Following the Mayer Rod film coating principle, for higher viscosity fluids, the gap film coating rod reduces clogging and eliminates scratches. By winding smaller wires at pitches (see photo), the cavity created is wide and shallow, allowing thick coatings to flow better. Smaller wires create smaller interruptions in the coating flow, allowing for more complete wetting of the coating.

RDS 130G# 3/8" Applicator rod 3/8 "Specifications

| LIST | VALUE |

|---|---|

| Production process | Interstitial wire-wound |

| WFT | 297.2µm |

| diameter | 9.52mm |

| Total length | 400mm |

| Application width | 300mm |

| material | stainless steel |

RDS 130G# 3/8" Applicator rod 3/8 " Packing list

Stainless Steel Rod X1 Transparent Encasement Hose X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- Advantages of Bar Spreader in corrosion coating prepative

- The overlooked role of Mayer Rods in laboratory wet-film preparation

130G# 3/8"

130G# 3/8"