KAIRDA NDT530 (F1) Galvanized Thickness Gauge with magnetic Induction Probe

Measurement range 0~1250μm, error range +/- 2%, resolution 0.1μm, probe contact parts plated hard chrome or ruby, durable, with automatic identification probe function, for measurement of magnetic metal substrate on the nonmagnetic Coating thickness.

KairDa

KairDa-

Defelsko Positector 6000 FJS3 fireproof coating Thickness Gauge 25mm

$ 2069.00 -

Defelsko PosiTector 6000 FT3 Coating Thickness Gauge

$ 1508.00 -

IWAVE WH-81 Coating Thickness Gauge magnetic thickness measurement method 0~1250μm

$ 166.00 -

LINSHANG LS-225-JIJIA hand pressure testing device rack

$ 359.00 -

Defelsko PosiTector 6000 NS1 galvanized Thickness Gauge, non-ferrous metal (aluminum, copper) substrate nonconductive coating

$ 1081.00

Introduction

Kaida NDT530There are two models of galvanized Thickness Gauges: NDT530 (F1) and NDT530 (N1), which are respectively connected to an external magnetic induction probe and an eddy current probe, which are used to measure the thickness of the non-magnetic coating on the magnetic metal substrate and the thickness of the non-conductive coating on the non-ferrous metal substrate, with a measurement range of 0~1250 microns and a measurement resolution of 0.1 microns.

Kaida NDT530The galvanized Thickness Gauge can be equipped with a variety of probes for measuring different coating thicknesses, with two measurement modes of continuous measurement and single measurement, two Operating Modes of direct HE grouping, and a data storage function that can store 100 readings.

Features

1、Kaida NDT530The galvanized Thickness Gauge has an automatic probe identification function.

2. Two measurement methods: continuous measurement and single measurement.

3. Two working methods: direct mode and group mode.

4. The contact parts of the probe of NDT530 (F1)/NDT530 (N1) galvanized Thickness Gauge are plated with hard chrome or ruby, which is durable.

5. The upper and lower limits can be set, and when the measurement result is greater than or equal to the upper and lower limit values, the coating Thickness Gauge will send out corresponding sounds or flashing lights.

6. Prompt the error through the screen display or buzzer.

7. AdoptionAluminum housing, small and portable, rugged and durable, suitable for harsh operating environments, with strong resistance to vibration, shock and electromagnetic interference.

8. Three calibration functions: with probe zero point calibration, one-point calibration, two-point calibration function, and basic calibration method can be usedcorrectSystematic error of the probe.

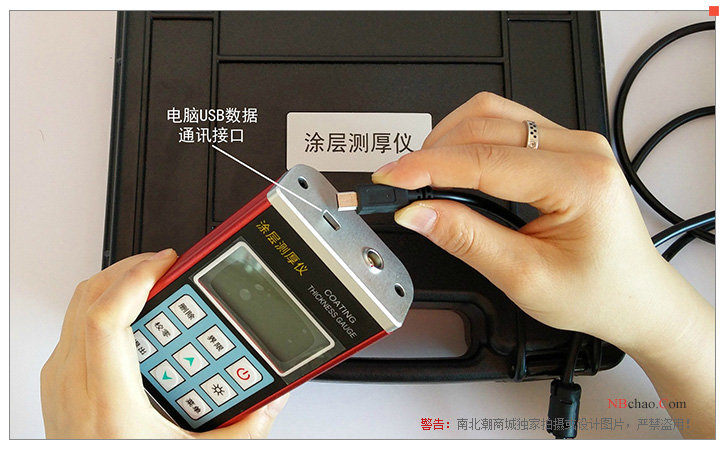

9. It can be optionally equipped with microcomputer softwareMeasurement value storage management,Rich functions such as transmission of measurement results, statistical analysis of measured values, and printing of measurement reports.

Applications

NDT530The galvanized layer Thickness Gauge is suitable for detecting the thickness measurement of fire protection layer, anti-corrosion layer, enamel layer, electroplating layer, paint layer, babbitt alloy tile, phosphate layer, aluminum tile, copper tile, paper and other fields in the fields of manufacturing, metal processing industry, commodity inspection, chemical industry and other fields.

Actual picture of the product

KairDa NDT530(F1) Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction |

| Measurement range | 0~1250μm |

| margin of error | ±2% |

| Resolution | 0.1μm |

| probe | Split F1 probe |

| Power Supply | 2 * AA 3V battery |

| Calibrated Certificate | without |

| system language | Chinese |

| Display screen | 128 * 64 dot matrix liquid crystal LCD |

| Interface | USB |

| supporting software | Yes. |

| Machine Weight | 340g |

| Machine size | 125*67*31 mm |

| Data storage | 100 Measured values, 5 groups |

| Unit display | μm/mils |

| Battery life | More than 200h (when the backlight is not turned on) |

KairDa NDT530(F1) Coating Thickness Gauge Packing list

Host x1, probe x1, calibration shim x5, battery x2, manual x1, warranty card x1, certificate x1, screw driver x1, data software x1, special instrument case x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 7991.5-2014

- ActiveISO 2178-2016

- ActiveASTM B499-2021

- ActiveISO 19840-2012

- ASTM E376-2019

- ActiveISO 2808-2019

- AbolishJJG 889-1995

- ActiveGB/T 4956-2003

- ISO 2361-1982

- ActiveGB/T 6463-2005

- AbolishGB/T 4956-1985

- AbolishASTM G12-07-2013

- ActiveJB/T 7663.2-2007

- ActiveJB/T 5000.12-2007

- AbolishGB/T 1764-1979

- ActiveGB/T 13452.2-2008

NDT530(F1)

NDT530(F1)