TQC DV2700 Rotothinner Rotational Viscometer available in 3 different shafts

Available in 3 modes: manual mode, maximum hold mode and timing mode. Excellent stable drive system for wider Measurement range and more accurate readings. High instrument accuracy and easy to use

TQC sheen

TQC sheen-

HUINUO SNB-1 Digital Display Rotational Viscometer Viscosity Testing Instrument with Ultra Low Viscosity Adapter

$ 1003.00 -

HUINUO SNB-2 digital display Rotational Viscometer Viscosity meter with L0 rotor

$ 1188.00 -

HUINUO NDJ-5S digital display Rotational Viscometer 100,000 CP printer

$ 542.00 -

NIRUN NTV-CAP1RV Cone-plate Viscometer Low shear rate, rotor required separately

$ 8725.00 -

CNSHP NDJ-4S Digital Rotational Viscometer

$ 455.00

The TQC Sheen Rotothinner Rotational Viscometer can be used in 3 modes: manual mode, maximum hold mode and timed mode.

The superior stable drive system creates a wider measurement range and more accurate readings. The instrument is highly accurate and easy to use, making it suitable for both research and production environments.

The Rotothinner Rotational Viscometer can easily and continuously detect material viscosity during the process of adding solvents and diluents to measure RFU viscosity. The Rotothinner Rotational Viscometer provides three different test ranges according to different rotating axes.

The Rotothinner Rotational Viscometer can also perform viscosity analysis at a user-selected time to obtain accurate data on shear performance, making it ideal for use in a production environment or laboratory.

A Rotational Viscometer has three measuring ranges:

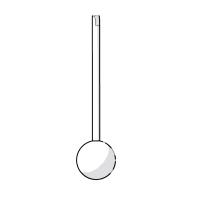

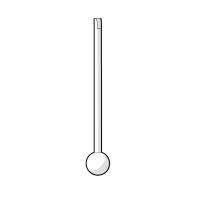

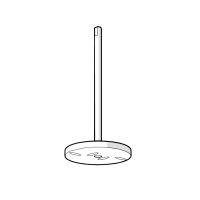

Rotothinner⢠is available in a variety of spindles*. There are three spindles available: one plate spindle and two ball spindles. These spindles cover three measuring ranges.

The plate spindle is used to determine the viscosity of fluids from 0 to 22 poise.

The large ball spindle can be used for measurements between 0-75 poise.

The small ball spindle is suitable for measurements between 0-350 poise.

In addition to spindles, a range of proven oil kits are available, complying with ISO 2884 and BS 3900 A7 standards.

*If you require an older model Sheen Rotothinner spindle, please contact us for availability and the correct item number.

Product Description

operate

The supplied tin container is filled with sample fluid and placed on a magnetic ring mounted on top of the base. Immerse the spindle into the sample fluid by lowering the handle. When the handle reaches the lowest point, the spindle begins to rotate at the set constant speed. The display shows the actual measured viscosity in poise.

reading

Readings for free-flowing fluids will stabilize quickly. More structured materials will require more time because the spindle will exert shear forces that affect the readings. That's why Rotothinner offers a variety of reading presets. Manual reading begins when the handle is at its lowest point. Continuous readings give continuous measurements. The Max Hold function displays the maximum reading, while the Read Time function provides the opportunity to automatically take readings at set intervals. An automatic display hold feature can be used to freeze readings for easier recording.

Easy to clean

After taking a reading, the handle can be raised to the level where the spindle is just below the edge of the sample container. This provides the operator with the opportunity to separate the sample material. When the handle is raised to a greater extent, the spindle automatically closes. Quick release chuck allows quick spindle changes and simplifies instrument and spindle cleaning.

Accurate and Repeatable The Rotothinner is microprocessor controlled, ensuring greater accuracy and repeatability. Automatic multi-point calibration improves accuracy.

Product advantages

Manual readings begin when the handle is at its lowest point.

Continuous readings give continuous measurements.

The maximum hold function displays the maximum reading.

The Read Time feature provides the opportunity to automatically take readings at set intervals.

An automatic display hold feature can be used to freeze readings for easier recording.

TQC sheen DV2700 Rotational viscoMeterSpecifications

| LIST | VALUE |

|---|---|

| Power | 100-240V / 50-60Hz |

| Operating temperature | +15~+35℃ |

| Net Weight | 8500g |

| Rotor speed | 562rpm |

| Repeatability | ±1%F.S |

| Measurement Accuracy | ±1%F.S |

| Measurement range | To be purchased separately: Spindle 1:0~22P~ 0~2200cP; Spindle 2:0,1~ 75P~ 10~7500cP; Spindle 3:1~ 350P~ 100~35000cP |

| Resolution | 0.1P,1cp |

| Dimensions | 200*360*550mm |

TQC sheen DV2700 Rotational viscoMeter Packing list

Host X1, power adapter X1, user manual (spindle and calibrating oil must be booked separately)

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Paint Viscosity and Viscometer

- Frequently Asked Questions for Viscometers in 2022

- Rotational viscometer calibration method

- How do Rotational Viscometer measurement results compare to Miscellaneous viscosity measurement methods?

- Common Types of Thickeners and Their Applications in the Coating Industry

- Principle characteristics and application analysis of spot inks viscosity Measurement Instrument

- Principle, application and selection of coaxial cylinder Rotational Viscometer

- Spinning & weaving dyeing and finishing auxiliary viscosity determination technology

- Application technology and quality control of Rotational Viscometer in pulp and paper manufacturing

- ActiveSJ/T 10454-2020

- ActiveHG/T 4443-2012

- ActiveHG/T 3323-2008

- ActiveJC/T 2217-2014

- AbolishGB/T 12008.7-2010

- ActiveJJG 1002-2005

DV2700

DV2700

DV2012

DV2012

DV2011

DV2011

DV2010

DV2010