CHINA CTG-800-1500F Paint Thickness Gauge, Integrated Iron-based Standard Type

Magnetic induction thickness measurement principle, super wear-resistant cemented carbide probe, thickness measurement up to 1500μm, measurement accuracy ± 2% + 1μm, reaction speed up to 0.3 seconds/time, with temperature compensation, can measure 1-5μm ultra-thin coating.

YiBai

YiBai-

TQC SP1114 Destructiveness Thickness Gauge Blade 4 Blade 2~ 200μm Range

$ 289.00 -

IPRE CT400 magnetic Induction eddy Current Coating Thickness Gauge Measurement range 0~1500μm

$ 258.00 -

Germany Knix QNix4500 dual-use Coating Thickness Gauge integrated probe 3mm range

Login -

Defelsko FNRS right angle probe for measurement of low headroom areas

$ 1262.00 -

German EPK probe N08 Cr eddy current Thickness Gauge probe, thickness range 0~80um

$ 1688.00

Introduction

CTG-800-1500F Coating Thickness Gauge is based on the principle of magnetic induction thickness measurement, which can quickly, without damage, and accurately measure the thickness of coating and coating. It can be used in both laboratory and engineering site. This instrument can be widely used in the detection fields of automobile industry, manufacturing industry, metal processing industry, chemical industry, commodity inspection and so on. It is the instrument required by the material protection profession.

CTG-800-1500F coating Thickness Gauge has backlight, large-screen digital display, single-point and multi-point calibration and other functions, and this product is resistant to high-low temperature, anti-drop, probe wear-resistant (more than 500,000 times), and test stability Well, the test speed is fast and it is suitable for various measurement environments. Its Specifications fully comply with national and international standards.

The Fe function detects the thickness of non-magnetic coatings on all magnetic substrates, such as paint applied to steel, iron, powder coating, plastic, porcelain, chrome, copper, zinc, etc.

Features

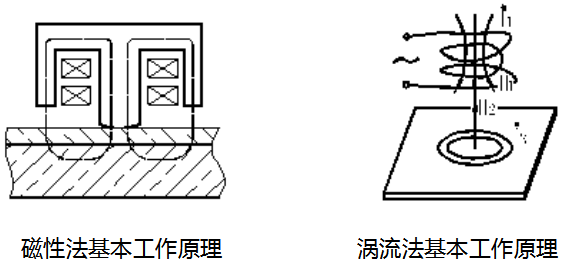

●Measurement method: F magnetic induction

●The spring guide sleeve probe with super wear-resistant carbide probe can ensure the probe has constant pressing force and stable sampling value when measuring on hard or rough surface;

●High precision, good stability, can measure 1-5μm ultra-thin coating;

●The measurement speed can reach 0.3 seconds/time;

●Large screen digital display is clearer;

●Two shutdown modes: manual shutdown and automatic shutdown;

●Wide measurement range and high resolution;

●Digital backlight display, no parallax, suitable for night use;

●Measurement mode: single measurement/continuous measurement;

●With metric and imperial unit conversion function, realize μm / mil conversion;

●The shell and internal structure are newly designed to enhance the product's appearance, drop resistance and impact resistance;

●Touch measurement accuracy is good.

YiBai CTG-800-1500F Integrated Iron Base Standard Coating Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | magnetic induction |

| Measuring range | 0 ~ 1500m |

| margin of error | ±2% |

| resolution | 0.1mm | 1mm |

| Minimum radius of curvature | F: convex: 1.5mm/concave 25mm |

| thinnest matrix | 0.3mm |

| Test environment | Non-magnetic coating on magnetic substrates |

| probe | Integrated probe |

| Power | 2 AA batteries (AAA) |

| Display screen | 4-Bit digital backlight LCD |

| Operating Temperature | -10-50℃ |

| Relative Humidity | <80% |

| Total Weight | 54G (without battery) |

| Complete-built unit size | 101*61*26mm |

YiBai CTG-800-1500F Integrated Iron Base Standard Coating Thickness Gauge Packing list

Host X1, standard piece X6, base X1, manual X1, battery X2, warranty card X1, certificate X1, portable case X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Characteristics of Solvent-Based Acrylic Coatings

- Definition and Applicable Criteria for Dry Film Thickness

- Destructive dry film thickness test and non-destructive dry film thickness test which is good? What standard is applied?

- Conductive and non-conductive coating thickness measurement and testing skills

- Frequently Asked Questions for Thickness Gauges in 2022

- What should I do if there is a negative number when the customer reports the Thickness Gauge measurement?

- How does the split coating Thickness Gauge measure the thickness of the three-proof paint of the aluminum LED lamp? [Video Demonstration]

- Application of Film Thickness Gauge in glue thickness measurement

- Thickness measurement of aluminum zinc nickel coating by coating Thickness Gauge

- Coating Thickness Gauge calibration method

- ActiveHG/T 3240-2007

- ActiveQJ 990.3A-2011

- ReplacedNF EN ISO 2808-2007

- ActiveGB/T 42541-2023

- ActiveGB/T 13912-2020

- ActiveGB/T 7991.5-2014

- ActiveGB/T 13448-2019

- ActiveISO 4526-2004

- ActiveJJG 818-2018

- ActiveGB/T 4956-2003

- AbolishGB/T 13448-2006

- ISO 6158-1984

- ActiveISO 1461-2022

- ActiveQC/T 484-1999

- AbolishGB/T 4956-1985

CTG-800-1500F Integrated Iron Base Standard

CTG-800-1500F Integrated Iron Base Standard

CTG-800-3000F Integrated Iron Base Standard

CTG-800-3000F Integrated Iron Base Standard