Miniature Coil Coating Tester, Heating Coil Applicator TBJ-JTH-DJ1 Automatic Winding and Unwinding

Applicator (composite) test for drum substrates, automatic winding and unwinding, adjustable roller application, with heating function, Temperature range room temperature~ 200 ℃ ± 3 ℃.

zy

zy-

CHINA Micro Coil Automatic Spraying and Coating Machine TBJ-JCPT-DJ1 Customized

$ 19016.00 -

UV UV curing coil coating machine Rxg-01/400uv automatic film laminating machine

$ 14280.00 -

Non-woven coil Coater Small coil film laminating machine, unwinding → scraping → drying → scraping → drying → film laminating → winding function

$ 22173.00 -

HuiNuo JTM-0.5/300 small continuous Coater with heating curing

$ 9228.00 -

CHINA NBC-6026D hydrogel Coater application width 480mm

Login

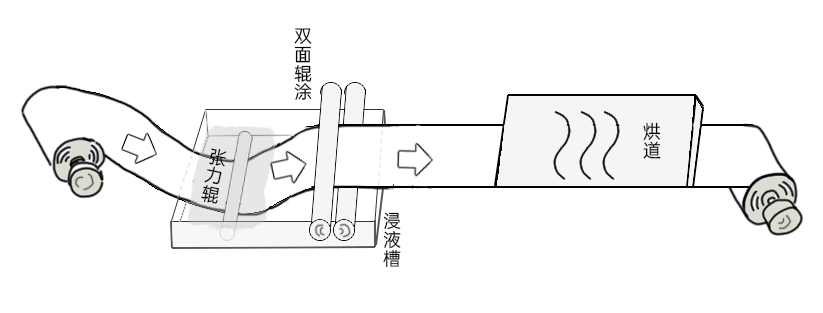

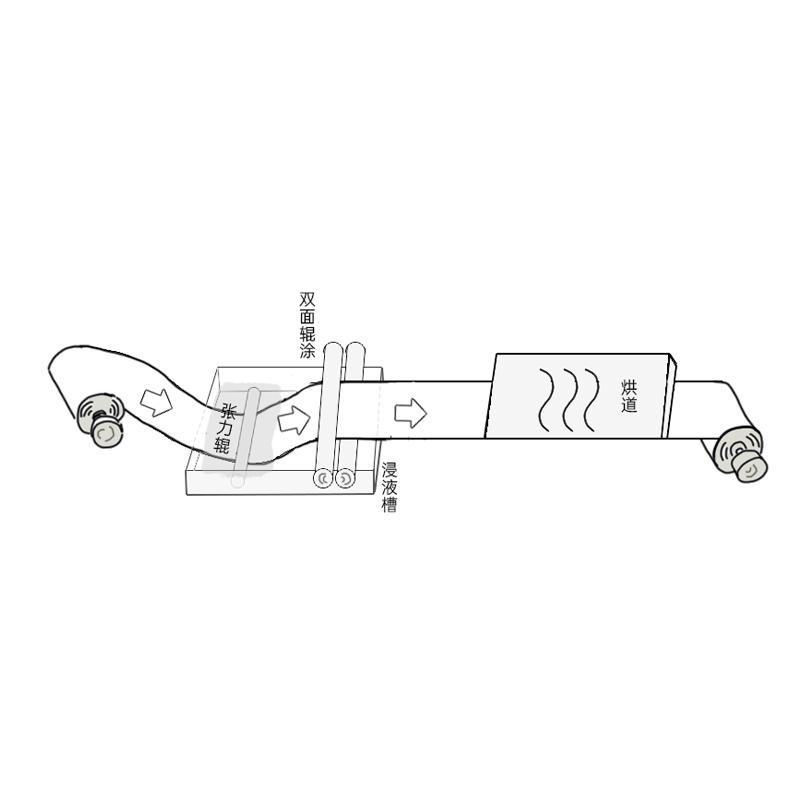

main part configuration

(1) Unwinding unit

Type: single station

Effective unwinding width: 400mm

Effective unwinding diameter: ≤φ400mm

Unwinding shaft: Inflatable shaft

Unwinding tension control: tension controller automatic control,

(2) Extrusion unit

Extrusion method: double roll extrusion

Double roll material: Plated Luo roll

Adjustable range: 0.3-10mm

Coating thickness: 0.3-10mm

Coating adjustment: hand wheel adjustment, dial gauge display

Coating accuracy: ±0.05mm

Dip tray material: 304 stainless steel

(3) Oven unit

Type: column arch bridge type; single side pneumatic top opening type

Length: Oven: 1000mm

Material: Stainless steel

Temperature: Room temperature~200℃±3℃

Temperature control: digital display temperature control meter automatic proportional temperature control

Insulation: The insulation layer is filled with glass fiber

(4) Winding unit

Type: single station

Effective winding width: 400mm

Effective winding diameter: ≤φ400mm

Rewinding shaft: Inflatable shaft

Winding tension control: tension controller automatic control,

zy TBJ-JTH-DJ1 Heating Coil CoaterSpecifications

| LIST | VALUE |

|---|---|

| Application mode | Adjustable roller application |

| Effective Application Width | 0-400mm |

| Application rate | 0-5m/min |

| Heating method | Stainless steel electric heating tube heating, centrifugal fan hot air circulation |

| Heating temperature range | RT+~200°C |

| Host Power | 220V 50Hz |

| Dimensions | ≈1500mmX600mmX750mm |

| Roll surface width | 400mm |

| Unwinding diameter | ≤ 400mm |

| winding diameter | ≤ 400mm |

| Unwinding Unit - Type | Single station |

| Unwinding Unit - Effective Unwinding Width | 400mm |

| Unwinding Unit - Effective Unwinding Diameter | ≤ 400mm |

| Unwinding Unit - Unwinding Reel | Inflatable shaft |

| Unwinding Unit - Unwinding Tension Control | Tension Controller automatic control |

| Extrusion Unit - Extrusion Method | Double roll extrusion |

| Extrusion Unit - Double Roll Material | Plating roller |

| Extrusion Unit - Adjustable Range | 0.3-10mm |

| Extrusion Unit - Application Film thickness | 0.3-10mm |

| Extrusion Unit - Application Adjustment | Handwheel adjustment, dial meter display |

| Extrusion Unit - Application Accuracy | ±0.05mm |

| Extrusion Unit - Dip Tray Material | 304 stainless steel |

| Oven Unit - Type | Column arch bridge type; unilateral pneumatic jacking type |

| Oven Unit - Length | Oven: 1000mm |

| Oven Units - Materials | stainless steel |

| Oven unit - temperature | Room temperature~ 200 ℃ ± 3 ℃ |

| Oven unit - temperature control | Digital temperature control meter automatic proportional temperature control |

| Oven Unit - Insulation | Glass fiber filled with insulation layer |

| Winding Unit - Type | Single station |

| Winding Unit - Effective Winding Width | 400mm |

| Winding Unit - Effective Winding Diameter | ≤ 400mm |

| Winding Unit - Winding Reel | Inflatable shaft |

| Winding Unit - Winding Tension Control | Tension Controller automatic control |

zy TBJ-JTH-DJ1 Heating Coil Coater Packing list

Complete-built unit x1, manual x1, certificate of conformity

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of Lab Film Applicator to Lubricating Material on Aramid Fiber Cloth [Video Demonstration]

- Comparative Analysis of Small Spreader and Traditional Roll-to-Roll Coater

- Detailed explanation of the selection method of PUR hot-melt adhesive laminating machine

- EVA Resin coater technology and operation method detailed explanation

- Research and Application of Waterproof Membrane Lab Film Applicator

- In-depth analysis of small coil coater technology and selection points

- Systematic understanding of coil isolation film coater

- Tape laboratory coater technology and film accuracy optimization elements analysis

- Fiberglass hot-melt adhesive coater technical analysis and operation guide

- Vacuum Film Applicator Technology Analysis: Breaking the Boundary of Surface Coating

TBJ-JTH-DJ1

TBJ-JTH-DJ1