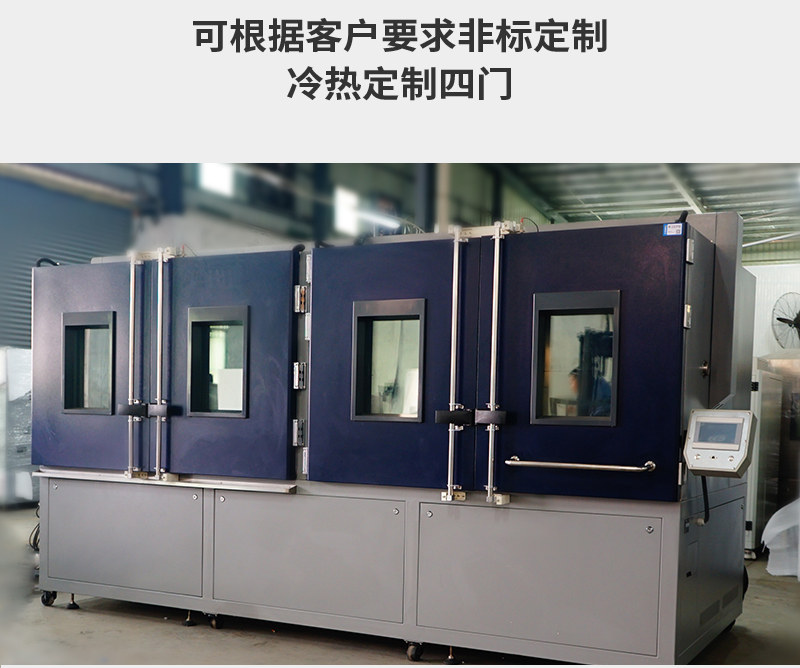

HUDA water-cooled hot and cold impact test box QD-E703-100K40 hatchback basket type

Low temperature Impact -40 ℃~ -10 ℃, high temperature Impact + 60 ℃~ + 150 ℃, capacity 100L, hatchback basket type, Water-Cooled refrigeration, automatic defrosting, suitable for metal, plastic, rubber, electronics and other materials industries, with USB interface.

HUDA

HUDA-

Aipei 3AP-CJ-150B Three-Chamber High and Low Temperature Impact Box Air-Cooled -55 ℃

$ 23610.00 -

FARUI FR-1219-150 (-40 ℃) triple-channel Thermal Shock Tester

$ 19790.00 -

FARUI FR-1219-50 (40 ℃) triple-channel Thermal Shock testing device

$ 16017.00 -

FARUI FR-1219-50 (-60 ℃) triple-channel Thermal Shock Tester

$ 21542.00 -

KESIONOTS Electronic High and Low Temperature Impact Tester KS-OTS-LR50LB Low Temperature -55 ℃/50L

$ 10696.00

Introduction

The thermal shock testing machine is a test equipment required by the metal, plastic, rubber, electronic and other material industries, which tests whether the product is adversely affected by the rapid change of high-low temperature in a way that the item to be tested does not move. It is generally used for electronic products, auto parts and high-tech products, etc., which require severe environmental conditions testing and inspection of high reliability and resistance requirements. All functions are controlled by computer, self-developed software, with a good operation interface, so that the user's operation and monitoring are more simple and intuitive, the hold function can keep the program you are running, you can temporarily change the value of this program segment, you can set the time and parameters on the screen, so that the refrigeration, heating, temperature switching switch, according to the set value is carried out automatically.

Meets standards

Comply with MIL STD, GB, JIS, JEDEC, IEC and other test specifications, GB/T2423.1-1989 low temperature test method, GB/T2423.2-1989 high temperature test method, GB/T2423.22-1989 temperature change test, GJB150.5-86 temperature shock test, GJB360.7-87 temperature shock test, GJB367.2-87 405 temperature shock test, Japanese industrial standard JIS, Industry Standard JESD22, Communication Industry Standard GR-1221-CORE, GBT 10589-2008 Low Temperature Test Chamber Technical Conditions, GBT 11158-2008 High Temperature Test Chamber Technical Conditions;

USB functionStandard features

1) The test curve data recorded in the controller can be transferred to the USB flash drive. Direct display and printing of test data/curves (with non-modifiable flags) via PC-specific software; or conversion of recorded data into Access data files that can be read by Microsoft Office.

2) The test curve data recorded by the controller are: 2 channel temperature - set temperature and actual temperature:

Program capacity and control functions

The number of programs that can be used: up to 120 groups, and the connection between programs can be set

RS-232 communication interface: curves can be displayed, and data acquisition can be used as a monitoring and remote control system

Mode of operation: program loop mode

Display resolution: temperature: 0.1°C, time: 0.1min

Oil separator: separates the refrigerated oil droplets mixed with the high temperature and high pressure refrigerant gas discharged from the compressor and returns to the compressor curved rail cavity for compressor lubrication and cooling

Drying and thrifty process: absorb residual moisture and acidic substances in the refrigerant of the refrigeration system, and filter out the solid impurity particles and copper pins in the system. Protects the normal operation of the expansion valve and capillary tube from ice and dirt blockage

Refrigerant: The environmentally friendly refrigerant R404A/R23 is used as the only medium of this refrigeration system

Safety protection device

Refrigeration system: compressor overheating, compressor overflow, compressor overpressure, condensing fan overheating

Test chamber: adjustable over-temperature protection, air conditioning channel limit over-temperature, fan, motor overheat relay

Others: Total Power Phase Sequence and Phase Loss Protection Leakage Protection Overload and Short Circuit Protection Ambient Temperature Overload Protection

Environmental conditions: The ambient temperature of the equipment should be kept within 0°C~±35°C Relative temperature: ≤85%

1. Requirements for storage environment

1) The ambient temperature of the equipment should be kept within 0°C~±45°C

2) When the ambient temperature is lower than 0°C, (the equipment stops for a long time) the water stored in the equipment should be discharged cleanly, so as to avoid the water in the pipeline from freezing and damaging the pipeline

2. Requirements for installation site

1) Please confirm the size required for the installation of the equipment

2)The distance between the left and right sides of the Test Chamber and the rear side wall plate shall not be less than 500mm, and the front distance shall not be less than 1000mm

3)When the equipment is running, enter the door, passage, elevator, etc., whether it can be entered, so as not to affect the progress of your company's project

controller

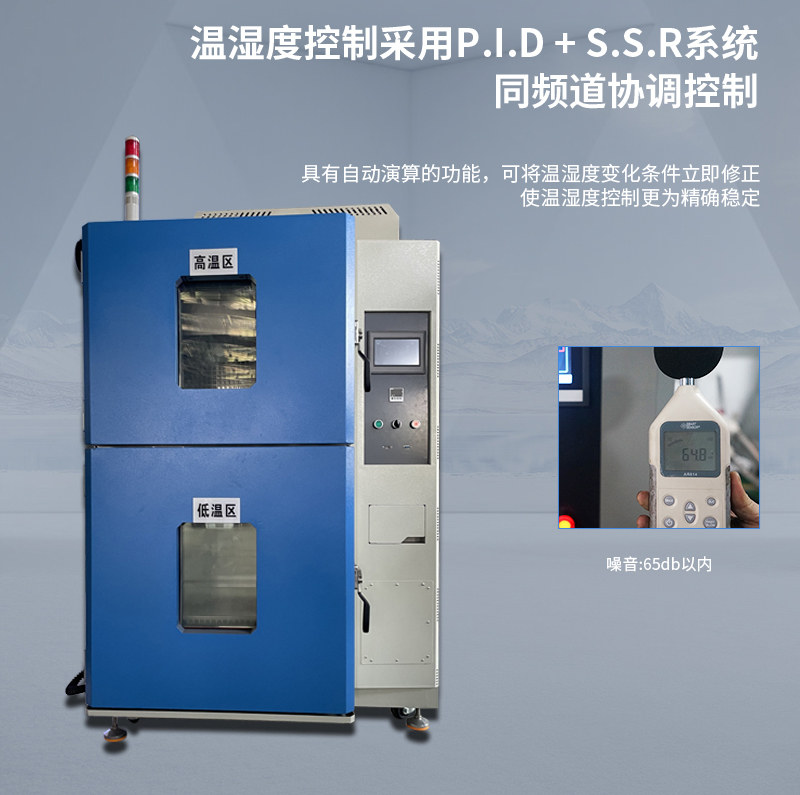

1) Imported LED digital display (P, I, D+S, S, R.) microcomputer integrated controller

2) Adopt human-computer interaction mode and touch input to allow users to quickly get started

3) The number of programs that can be used: up to 120 groups

4) Repeatable commands: each command can be executed 9999 times

5) Time setting: 0~99 hours 59 minutes

6) The graphical curve can be displayed in real time when the program is executed

7) Display content: temperature setting (SV), actual (PV) value, execution period, program curve execution function, running time, number of stages, running time, remaining time, fault status and failure time

8) There is a function of skipping files and holding during program execution

9) Language selection: You can switch between Chinese and English

10) The production of the program adopts the dialogue type, with editing, clearing, and other functions

11) With 3 sets of time signal output control (can control the DUT ON/OFF action)

12) It has 4 sets of PID parameter settings

13) RS-485 interface

14) It has the function of appointment start + appointment shutdown

15) When the machine fails, the fault screen will be displayed and the buzzer will sound loudly

16) It has the function of power-off program memory, automatic start and continuous execution of the program after resumption

17) USB storage function: backup internal parameters, program setting, operation curve recording, U disk memory

Main accessories and origin

| serial number | Origin | Model brand | The name of the accessory |

| 1 | France | Taikang | Compressors (2 units) |

| 2 | Taiwan, CHINA, CHINA | Youyi | controller |

| 3 | CHINATaiwan, CHINA | CHINT | Contactors |

| 4 | CHINATaiwan, CHINA | Pine poplar | sensor |

| 5 | Denmark | Danfoss | desiccator |

| 6 | Denmark | Danfoss | High Voltage protector |

| 7 | Japan | Heron Palace | Solenoid valves |

| 8 | Denmark | Danfoss | Oil separators |

| 9 | CHINATaiwan, CHINA | Rain Field | Circulating fan motor |

| 10 | CHINATaiwan, CHINA | Vad | Heater (Nichrome) |

| 11 | CHINATaiwan, CHINA | Guoxin | heat exchanger |

| 12 | CHINATaiwan, CHINA | Yongqiang | evaporator |

| 13 | CHINATaiwan, CHINA | Shang Yi | Circulating wind wheels |

| 14 | United States | Emerson | Shock-resistant hose |

| 15 | CHINATaiwan, CHINA | Zhuo Yi | Solid state relays |

| 16 | CHINATaiwan, CHINA | Yongqiang | condenser |

| 17 | United States | R404a | Refrigerant DuPont |

| 18 | Chinese | R23 | Refrigerant DuPont |

| 19 | CHINATaiwan, CHINA | CHINT | Thermal relays |

| 20 | CHINATaiwan, CHINA | CHINT | AC contactors |

| 21 | CHINATaiwan, CHINA | Yongqiang | blister |

| 22 | CHINATaiwan, CHINA | Guoxin | Plate exchanger |

| 23 | Japan | Omron | Miniature relays |

| 24 | Denmark | Danfoss | Filter driers |

| 25 | CHINA | Liangling | Cooling water towers |

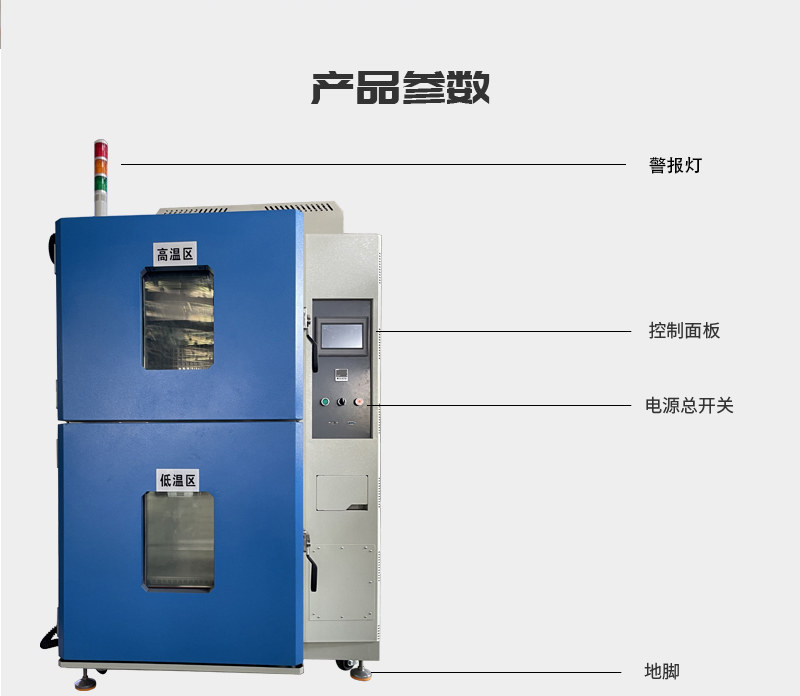

HUDA QD-E703-100K40 Thermal Shock Test ChamberSpecifications

| LIST | VALUE |

|---|---|

| Temperature range | -40℃~+150℃ |

| High Temperature Impact Range | +60℃~+150℃ |

| Low Temperature Impact Range | -40℃~-10℃ |

| High Temperature Impact Range | +60℃~+170℃ |

| Low Temperature Impact Range | -10℃~-55℃ |

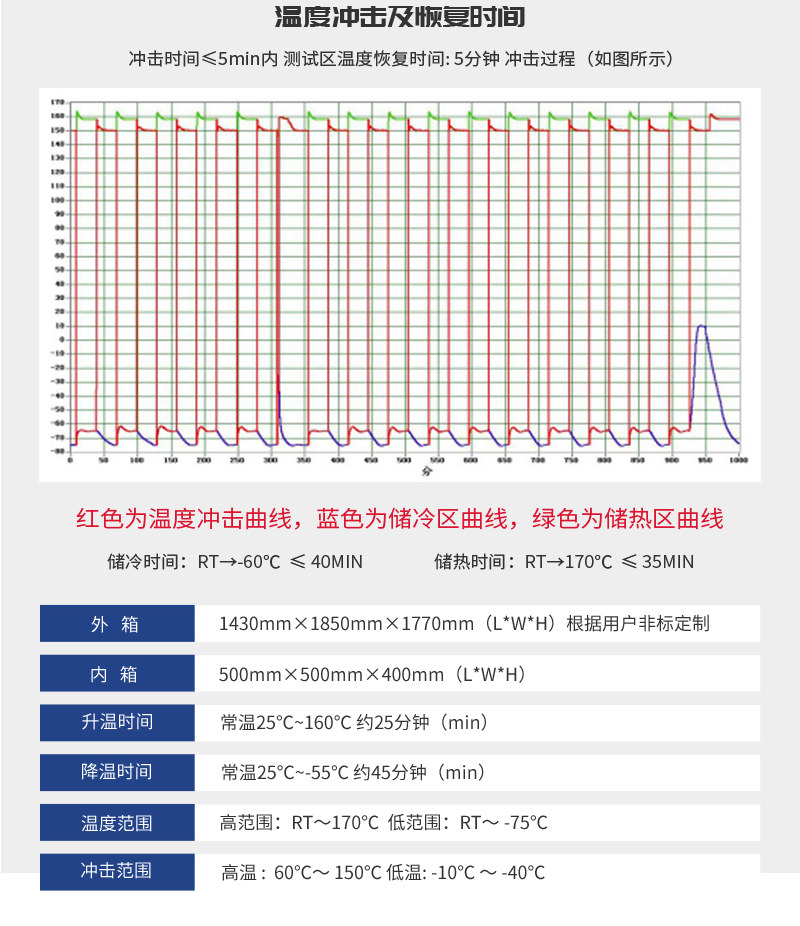

| Impact thermostatic time | 30 minutes each |

| According to measurement specifications | Measure the SENSOR placement point, 1/10 of the inner size of the inner box wall |

| Dimensions | 1455*1790*1980mm |

| Basket size | 400*500*500mm(W*H*D) |

| Inner Volume | 150L |

| Heating time | RT+25°C→170°C≈35min |

| Preparatory cooling time | RT+25°C→-55°C≈55min |

| temperature residence time | 30 minutes each for high and low temperatures (min) |

| Impact Recovery Time | -40℃~+150℃ |

| Mobile transition time | ≤ 10 seconds, stable within 3-5 minutes |

| Test tank conversion travel time | ≦10S |

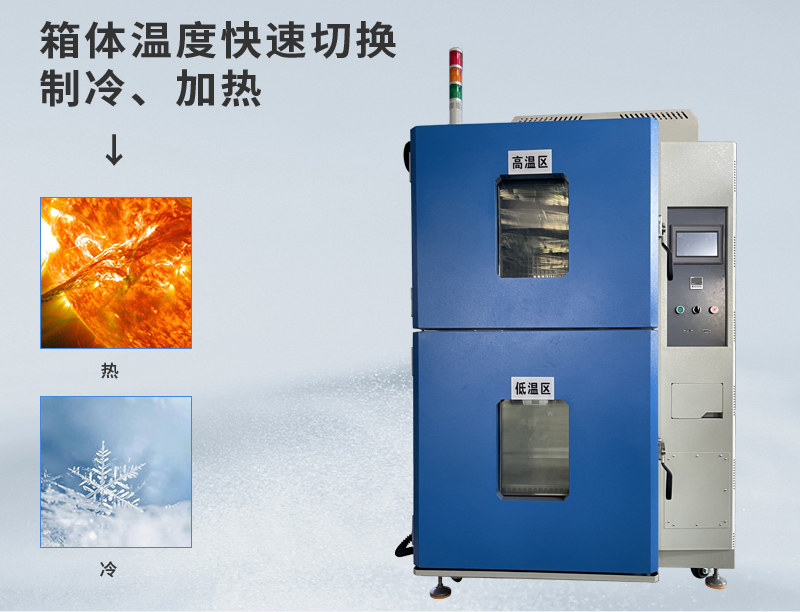

| Test method | During the test, the object to be tested moves and switches between the high temperature tank and the low temperature tank to achieve the purpose of heat & cold shock test |

| Weight | About 550kg |

| Allowable Voltage fluctuation range | 10% |

| Allowable Frequency Range | 50±1Hz |

| Operating Conditions | Ambient Temperature is 0~ + 35 ℃, Relative Humidity < 85% |

| Analytical Accuracy | 0.1℃ |

| Time Accuracy | 0.1min |

| Temperature Fluctuation | ±0.5℃ |

| distribution uniformity | ±2.0℃ |

| Air conditioning channel | Built-in high temperature zone, low temperature zone air valve, loop air duct and stainless steel loop fan, by switching the basket, the test product is sent to the heat and cooling space; so as to achieve rapid temperature alternation and uniform indoor temperature distribution |

| Low temperature zone mechanical room | Evaporator, loop fan, cold storage sheet, heating device, loop wind wheel, volute |

| High temperature zone machinery room | Heating device, loop fan, pressure equilibrate, loop wheel, volute |

| Distribution control cabinet | Total power circuit breaker, Controller, switchboard, cooling fan, over-temperature protector, cylinder, pressure protector, liquid storage tank, air-cooled condenser, refrigeration unit |

| Heating system | Using scale heat dissipation heating pipe P.I.D to control heating to achieve temperature equilibrate |

| Refrigeration system | Adopt water-cooled heat exchanger |

| chiller | Water circulation cooling use |

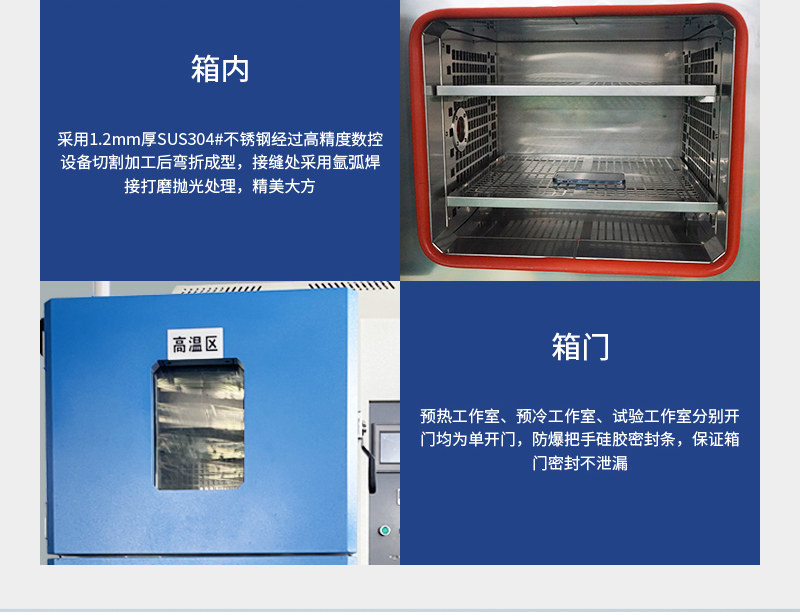

| Test material rack | Stainless steel SUS #304 punching rack 2 pieces (load-bearing 20kg) adjustable spacing |

| Operating Mode | The cold zone, the hot zone, and the two boxes are matched by moving the test product, the low temperature tank is connected with the test chamber, and the basket is instantly introduced into the low temperature test chamber; when the impact is high temperature, the basket is instantly introduced into the high temperature test chamber. |

| input | Thermocouple |

| centrifugal fan | Low noise multi-wing centrifugal fan |

| Heating system | Imported nickel-chromium alloy electric heating device |

| Heating Control mode | Equiperiodic pulse without touchpoint (solid state relay) |

| Control mode | Anti-integral saturation PID, BTC equilibrate temperature control mode (temperature test equipment) |

| subsidiary function | Fault alarm and cause, processing prompt function, power failure protection function, Upper/Lower limit temperature protection function, self-diagnosis function, automatic stop function |

| Software Operating Environment | IBM PC compatible machine, CPU above PH, memory above 128M, Simplified Chinese windows2000 or Simplified Chinese windowsXP, win7 system |

| Software Operating Environment | 配套数据分析软件 |

| Temperature measurement | T Thermocouple |

| Refrigeration system | Water-cooled shell and tube condenser, chilled down water tower |

| Refrigeration system | German import blog low temperature compression |

| Evaporator | finned tube heat exchanger |

| Evaporative condenser | The plate heat exchanger using high temperature copper fiber welding has small surface area, small energy loss and high heat exchange efficiency |

| Throttle device | Thermal expansion valve, capillary tubing |

| Number of programs available | Maximum 120 groups, connection can be set between programs |

| RS-232 Communication interface | Linear dispersion display, data collection, can be used as monitoring and remote Control system |

| Operation mode | Program loop mode |

| Display resolution | Temperature: 0.1 ℃; Time: 0.1min |

| display | 5.7 LCD color display |

| refrigerant | Environmentally friendly refrigerant R404A/R23 |

| Refrigeration system protection device | Compressor overheating, compressor overcurrent, compressor overpressure, condensing fan overheating |

| Protection device | Adjustable over-temperature protection, air conditioning channel limit over-temperature, fan, motor overheating relay |

| Protection device | Total Power phase sequence and phase loss protection, leakage protection, overload and short circuit protection, Ambient Temperature protection |

| Environmental conditions | Ambient Temperature should be kept within 0 ℃~ +/- 35 ℃, relative temperature: ≤ 85% |

| Wind path mechanism | Pneumatic cylinder actuation mechanism |

| Control mode | Adopt touch programmable temperature Controller |

| Protection device | Overcurrent protection switch; line fuse; over temperature protection switch; compressor and motor overload protection switch; refrigerant high Voltage protection switch |

| Accessories | 2 compartment racks |

| Power | The power cord is 3-phase 5-wire 30A, 380V, 50HZ, Wire diameter 4 square, grounding 2.5 square |

| Power | 15KW |

| Liner material | Stainless Steel Plate (SUS #304) |

| Enclosure Material | Cold Rolled Steel Electrostatic Spray Paint (CR) |

| test hole | 1 50mm hole at the top of the body is attached with 1 stainless steel hole cover and 1 silicone plug. |

| Thermal insulation material | High temperature tank: 24k Glass cotton; Low temperature tank: High density PU foam + Glass cotton |

| Box door | Panel door, left open; a. Flat recessed handle; b. Concealed hinge |

| Sealing device | Silicone foam pressing |

| Sample placement rack | A. Stainless steel SUS #304 mesh storage tray 2 pieces; b. Stainless steel adjustable spacing shelf hanging hook type 8 pieces |

| Heat exchange system (water-cooled special) | Water tower: 8RT low noise, corrosion resistance, power saving and environmentally friendly water tower; water pump: 1HP high lift silent motor; condenser: water-cooled shell and tube condenser |

| Air supply circulation, drainage system | A. 4 motors; b. Stainless steel elongated shaft; c. SIROCCO FAN; d. Drainage system |

| Heating system | Fully independent system, efficient bare wire heating |

| Refrigeration system | 2 sets imported from France Taikang |

| refrigerant | Environmentally friendly refrigerant |

| Refrigeration system | Air-cooled with cooling motor/water-cooled shell and tube condenser |

| Evaporator | Fin type multi-stage automatic load Capacity adjustment |

| expansion system | Danfoss expansion valve |

| Evaporator | Fin type multi-stage automatic load Capacity adjustment |

HUDA QD-E703-100K40 Thermal Shock Test Chamber Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- What parts of Thermal Shock Test Chamber need to be cleaned frequently?

- How to distinguish between low/high Temperature Test Chamber and heat & cold shock chamber

- Thermal Shock Test Chamber FAQ and calibration method

- What are the similarities between the two-box thermal shock Test Chamber and the Three-Chamber thermal shock Test Chamber?

- What is the difference between the two-box thermal shock Test Chamber and the Three-Chamber thermal shock Test Chamber?

- What is the difference between the two-box thermal shock Test Chamber and the Three-Chamber thermal shock Test Chamber?

- What are the precautions for using a thermal shock Test Chamber?

- Introduction of operating conditions and safety protection devices of thermal shock Test Chamber

- What is the composition of the refrigeration device of the two-box thermal shock Test Chamber?

- What is the difference between a thermal shock Test Chamber and a high-low temperature shock Test Chamber?

- IncomingGB/T 46603-2025

- ActiveJG/T 572-2019

- ActiveGB/T 7991.3-2021

- ActiveGB/T 2423.22-2012

- ActiveGJB 150.5a-2009

- ActiveGJB 150.5-1986

- ActiveGB/T 2423.22-2002

QD-E703-100K40

QD-E703-100K40