HUDA high-low temperature rapid change testing machine QD-E708-1000K60-X10

Volume 1000L, Temperature range -60 ℃~ 150 ℃, linear temperature rise and drop 10 ℃/min, in line with GB standards, self-developed multi-channel, multi-stage throttling refrigeration system, remote visual control, application of broadband compression equilibrating temperature control system.

HUDA

HUDA-

BOZHEN GDW2005 low/high Temperature Test Chamber -20~130 ℃/50L

$ 3125.00 -

HZAOC GDJW-150A high-low temperature cyclic Test Chamber -20-150 ℃/150L

$ 6355.00 -

HZAOC GDJW-010D Component Stress Test Chamber -60 ℃~ 150 ℃/1000L

$ 11849.00 -

ZKHS GDJS-100C high-low temperature Humidity Cyclic Chamber -40~150 ℃/100L

$ 8107.00 -

HZAOC GDJW-800B high-low temperature cyclic Test Chamber -30-150 ℃/800L

$ 10112.00

Overview

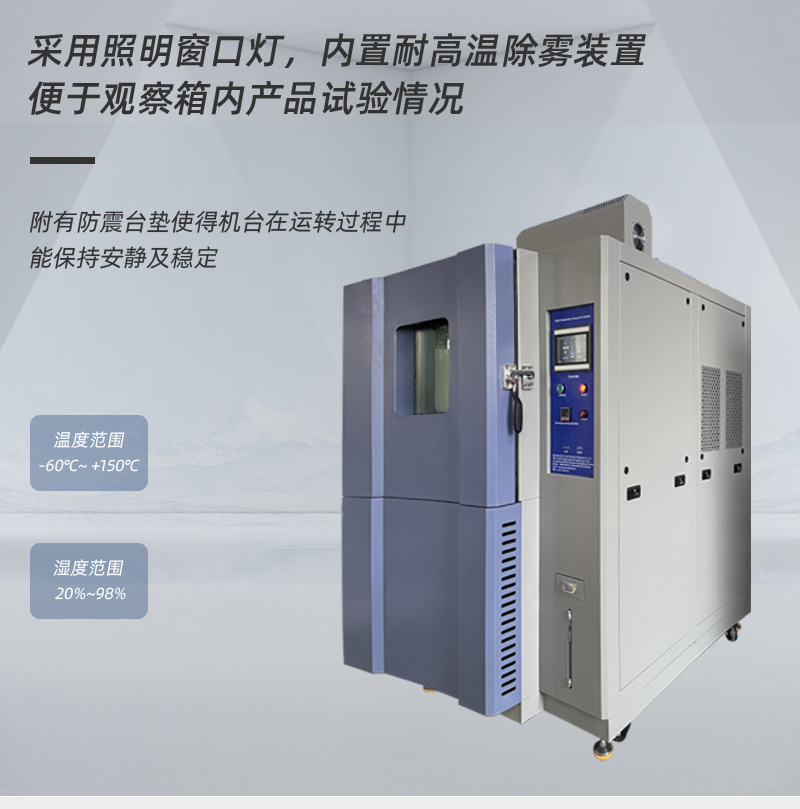

This laboratory can be used to determine the adaptability of electronic products, automobile parts, materials, etc. to use and storage under conditions of high humidity, low humidity, constant humidity and heat, rapid alternating cycles of high-low temperatures, and humidity and heat that produce condensation on the surface.

This testing machine adopts the latest reasonable structure and stable and reliable control method, making it beautiful in appearance, easy to operate, safe, and with high precision in temperature and humidity control. It is ideal for rapid temperature change tests, constant temperature and humidity tests, and alternating humidity and heat tests. professional equipment.

Product advantages

1. Utilize a multi-channel, environmentally friendly and energy-saving (low noise) mechanical compression refrigeration system.

All materials, parts, components, raw materials, etc. of this equipment are made of environmentally friendly products, whether domestic (CN) or imported. According to the characteristics of mechanical compression refrigeration, a two-stage multi-channel main bypass system is adopted. The multi-channel main circuit and bypass can be used according to different tasks. The condition adaptive selection is enabled, and the entire control is automatically realized by the intelligent control system according to the Operating Conditions, changing the traditional way of using a thermostat to control the heater to offset the cooling capacity to control the cooling capacity. In order to achieve the effect of energy saving, not only the energy consumption accounts for only 80% of similar products. It also reduces the operating load of the refrigeration compressor, reduces equipment vibration and noise, and improves control accuracy. In order to better achieve energy-saving effects, frequency conversion technology is also used to adapt the refrigeration output of the refrigeration compressor to various temperature change rate requirements in the laboratory, while controlling the power loss to achieve energy-saving effects. Use sound absorption and silencing methods in different places throughout the structure and during mechanical work to reduce the noise of the entire equipment.

2. Self-developed multi-channel and multi-level throttling system (refrigeration system).

The refrigeration system of this equipment is designed with different main capillary paths and bypasses according to different Operating Conditions of the system. It is automatically controlled according to the Operating Conditions through the Zhitong control system, and the automatically adjusted capillary throttling system ensures that the flow size is adjustable and achieves the purpose of temperature change. , and the temperature field changes uniformly, with minimal temperature fluctuations.

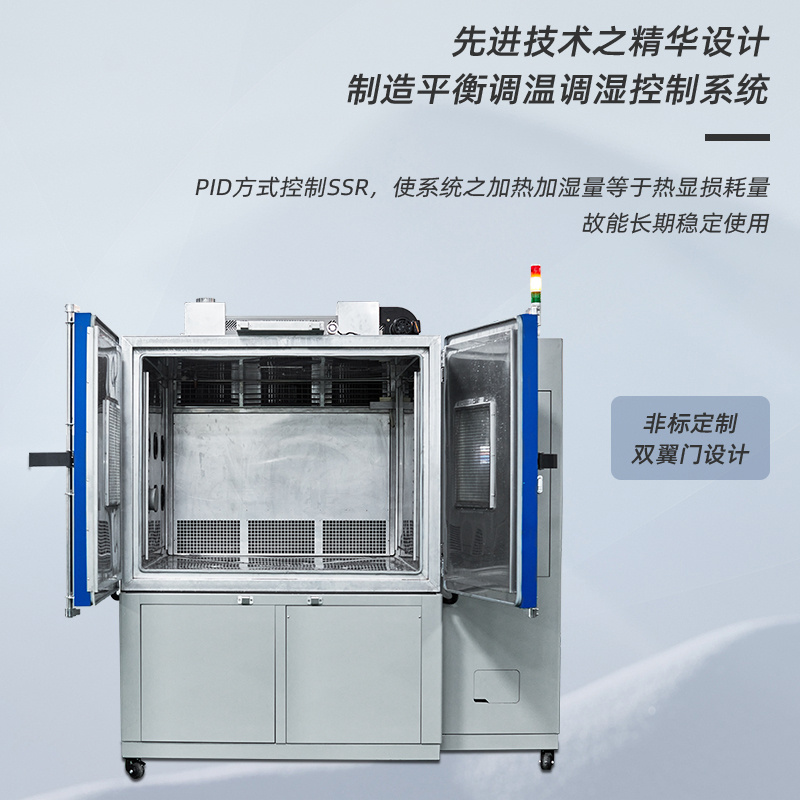

3. Apply the broadband pressure balance temperature regulation system to achieve rapid temperature control through the fast convergence PID adaptive algorithm.

The use of temperature adjustment chamber, static pressure chamber and forced air duct system of centrifugal fan blades ensures sufficient exchange of cold and heat and uniform air supply through the top orifice plate to each space of the studio (experimental area). To achieve temperature uniformity; in order to achieve rapid temperature convergence, our company cooperated with South Korea's Sanyuan Company to develop a dedicated PID adaptive algorithm suitable for our company. This control method continuously corrects the control according to the temperature situation during the control process. It achieves the control purpose of retracting the sword quickly, with small temperature overshoot and high stability.

4. Realize remote visual control.

The equipment is equipped with a human-machine management interface and a touch-mode automatic control system to achieve automatic control; at the same time, it can be connected to a remote computer for remote monitoring through the RS485 communication interface. Through the graphical interface, the entire system has simple and fast control and management, automatic fault prompts, graphical prompts for fault energy saving and solutions, and guides users to quickly troubleshoot.

Implementation standards

1. GB2423.1-2008/IEC6008-2-1-2007 Part 2: Test Method Test A: Low Temperature

2. GB/T 2423.2-2008 Part 2: Test Method Test B: High Temperature

3. GJB150.3A-2009 High Temperature Test Method

4. GJB150.4A-2009 Low temperature test method

5. GB2423.22-2008 Environmental testing of electrical and electronic products Part 2 Test Nb: Temperature change with specified temperature change rate

6. GBT 2424.5-2006 Performance confirmation of environmental testing Temperature Test Chamber for electrical and electronic products

7. GB/T 10589-2008 Technical conditions for low Temperature Test Chamber

8. GB/T2423.3-2008(IEC68-2-3) Test Ca: Constant damp heat test method

9. GJB150.9A-2009 Damp heat test method

10.G/BT 2423.4-2008/IEC6008-2-30:2005 Test Db: Alternating moist heat method

11.GB/T5170.18-2005 Basic parameter verification method for environmental testing equipment for electrical and electronic products Temperature/humidity combined cycle testing equipment

12.GB/T10586-2006 Technical conditions of damp heat Test Chamber

13.GBT 2424.6-2006 Performance confirmation of temperature and Humidity Test Chamber for environmental testing of electrical and electronic products

14.GBT 2424.7-2006 Measurement of environmental Test Chambers for electrical and electronic products A and B (with load) Temperature Test Chambers

Structure and composition

| Equipment layout | The control box and test box are integrated. The test space is located on the upper left side of the equipment, the refrigeration machinery room is located below the equipment, the electrical control box is located on the upper right side of the equipment, and the water supply tank is located on the lower right side of the equipment. |

| Sealing strip: silicone sealing strip | |

| The circulation fan is located on the top of the equipment Test Chamber | |

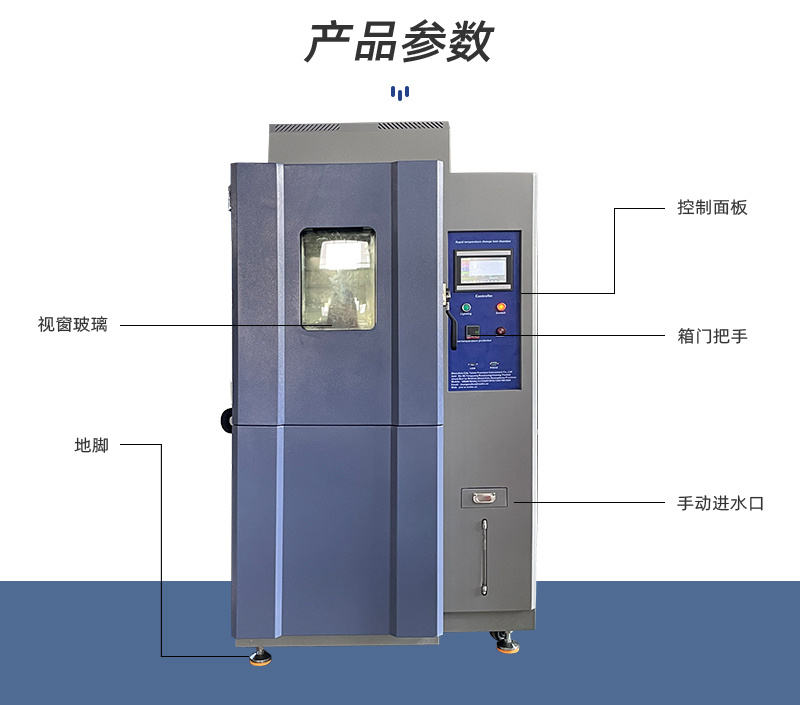

| The Test Chamber door is installed in front of the Test Chamber, and an observation window is set on the door. | |

| Set a test hole in the center of the left side of the device | |

| Drainage holes, power cable holes and main power supply switch are provided behind the equipment. | |

| Mobile casters and positioning foot cups are installed at the bottom of the box. | |

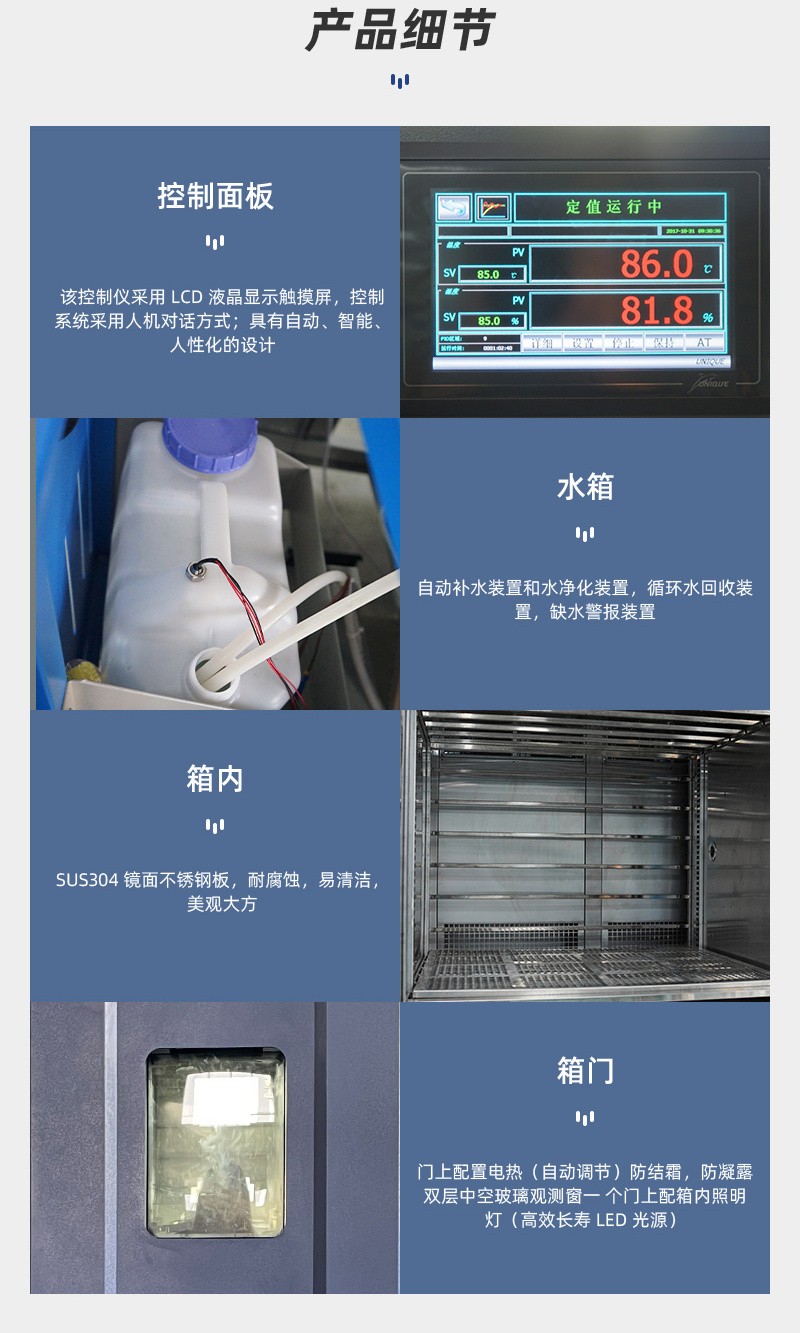

| Inner box material | It is made of SUS304# stainless steel plate, cut with precision laser cutting equipment and bent on a CNC folding machine, then fully welded with argon arc welding, polished and polished; the steel plate is 1.2mm thick; there are sample rack tray supports on both sides of the inner box. Indexing rack, adjustable spacing between sample racks |

| Enclosure Material | It is made of cold-rolled steel plates, cut with precision laser cutting equipment and bent on a CNC folding machine, and then welded and polished using argon arc welding. After the overall pickling and rust removal of the steel plate surface, the surface is treated with high-temperature baking paint, which is different from the usual The exterior spray treatment is more beautiful and elegant in appearance and enhances its anti-corrosion and anti-rust properties; the steel plate is 1.2mm thick |

| Insulation material | Made of polyurethane rigid foam + glass fiber cotton, the insulation layer is 100mm thick. It has better insulation performance than ordinary insulation cotton. It has good performance in saving electricity and reducing the impact on the peripheral ambient temperature of the equipment. |

| air circulation system | When the test sample is placed in the test space, the uniformity of temperature and humidity on the surface of the sample needs to be ensured, and the air flow in the test space needs to be forced to circulate. This equipment has built-in air room, circulating air duct and stainless steel circulating fan. Through the top back leaf window and diffuser, the wind is evenly blown out from the top, and the temperature and humidity adjusted in the mixing chamber are distributed to the test space, thereby achieving uniform The purpose of controlling temperature and humidity |

| box door | Single door, explosion-proof handle |

| Anti-condensation electric heating device | |

| Vacuum automatic defogging transparent window and window lighting | |

| Insulation layer rigid polyurethane foam + fiberglass | |

| Lead test hole | Open a Φ50mm test hole and attach corresponding thermal insulation accessories and special sealing plugs. |

| Observation window | Transparent electric heating film hollow tempered glass (located on the door) (with anti-condensation function) |

| control Panel | Taiwan, CHINA Taitong LCD touch programmable controller, adjustable over-temperature protector, emergency stop button switch, lighting switch, main power switch, RS-232 communication interface |

| Refrigeration machinery room | Refrigeration units, cooling fans, drainage devices, refrigeration control accessories |

| Test material rack | It is made of SUS304# stainless steel and punched and bent into a mesh shape. It is easy to use. The distance between the material racks is adjustable. Two pieces are standard. |

| Power distribution control cabinet | Main power circuit breaker, controller, distribution board, cooling fan, over-temperature protector |

Refrigeration system features

A. The entire system pipeline is subjected to a leak test with ventilation and pressure of 22kg.

B. The heating and cooling systems are completely independent.

C. It is equipped with the company's professional technical features to prevent high-temperature and high-pressure airflow from co-current cooling machine damage to the system.

D. All refrigeration system action programs are completely controlled by the microcomputer controller.

E. There is a water collecting pan at the bottom of the compressor, which can collect the condensation water caused by frost.

F. The compressor is equipped with a PTC temperature sensor. When the compressor is over-temperature, over-temperature protection is implemented.

G. The compressor is equipped with an oil pressure protector to protect the compressor oil pressure.

H. High-low pressure protection devices monitor the refrigerant pressure during the operation of the equipment. Once the refrigerant pressure is higher than the system's ultimate pressure or lower than the minimum pressure set by the system, an alarm will be issued immediately and the power will be cut off until troubleshooting.

I. The refrigeration system all uses imported brand accessories, with reliable quality and ensuring the stability of the system.

Screen display function

Temperature and humidity setting (SV) actual (PV) value is directly displayed

Can display execution program number, segment, remaining time and number of cycles, as well as running time display

Program editing and graphic curve display

Equipped with a separate program editing screen, each page can input 4 segments of temperature, humidity and time.

Fixed point or program action status display

Language conversion can switch Chinese/English

57 true color display screen

Program capacity and control functions

Number of programs that can be used: Maximum 120 groups, one program can be composed of 1 to 100 segments

Usable memory capacity: 1200 segments, commands can be executed repeatedly: each command can be executed up to 999 times

The program slope setting can be set by the time axis, with functions such as editing, clearing, and inserting.

Each program can be set to a maximum of 99 hours and 99 minutes, with a minimum of one minute. It can be set to be used in conjunction.

Equipped with 4 sets of time signal output control (can control the ON/OFF action of the object under test)

Has 9 sets of PID parameter settings

It has segment skip and hold functions during program execution.

The backlight of the screen can be adjusted and the backlight time can be set

The screen display protection function can be set to be turned off at a scheduled time or manually.

Program copying, COPY, connection function, editing experiment title and other program editing functions

PID automatic calculation and FUZZY control function

It has power-off program memory and can automatically start and resume program execution after power is restored.

With scheduled startup and shutdown functions

With date and time adjustment function

Button and screen lock (LOCK) function

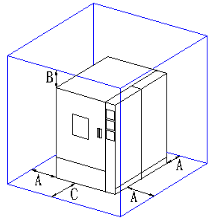

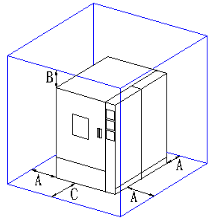

Installation site requirements

The ground is flat, well ventilated, and does not contain flammable, explosive, corrosive gases and dust; there are no strong electromagnetic radiation sources nearby;

Site ground load-bearing capacity: not less than 600kg/m2;

Leave adequate maintenance space around the equipment.

A: Not less than 400mm

B: Not less than 400mm

C: Not less than 1000mm

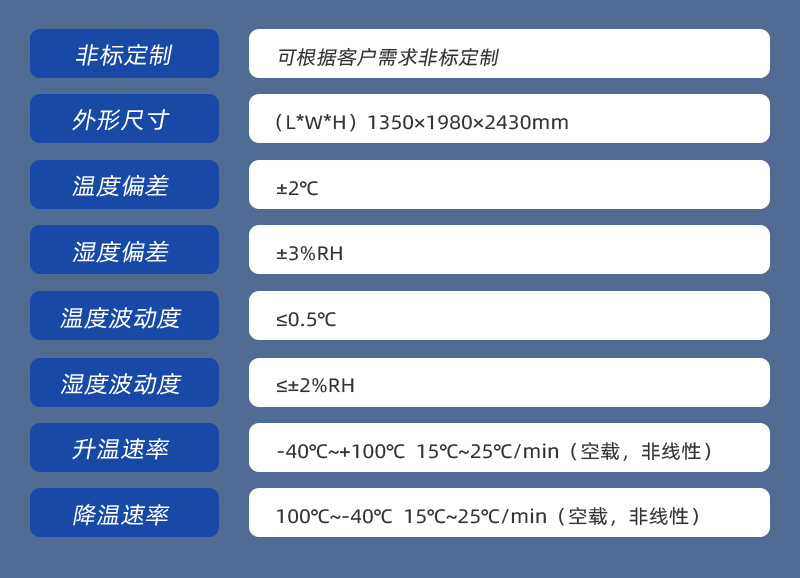

HUDA QD-E708-1000K60-X10 Rapid temperature change Test ChamberSpecifications

| LIST | VALUE |

|---|---|

| Temperature range | -60~150℃ |

| Humidity control range | 20~98%R.H |

| Interior Volume | 1000L |

| Interior size | 1000*1000*1000mm |

| Dimensions | ≈1550*2330*2480mm |

| Weight | About 1000 kg |

| Maximum Power | 50KW |

| Maximum current | 75A |

| Power | AC380V three-phase four-wire system + protective grounding N; Voltage allowable fluctuation range 10% V; Frequency allowable fluctuation range 50 +/- 0.5HZ; TN-S mode Power Supply or TT mode Power Supply; protective grounding resistance less than 4Ω |

| Temperature Resolution | 0.01℃ |

| Humidity resolution | 0.1%R.H |

| Temperature deviation | ±1℃ |

| Humidity Deviation | ±2%R.H |

| Temperature Uniformity | ≤2℃ |

| Humidity Uniformity | ±3%R.H |

| Temperature Fluctuation | ±0.5℃ |

| Humidity stability | ±2%R.H |

| linear Cooling rate | 10 ℃/min (under no-load conditions) |

| Refrigeration system | Low temperature compressor imported from Germany |

| Dehumidification system | Adopt fully enclosed compressor dehumidification |

| refrigeration method | Blisters chill down |

| Evaporator | finned tube heat exchanger |

| Evaporator | Plate heat exchanger brazed by high temperature copper |

| Throttle device | Thermal expansion valve, capillary tubing |

| Control mode of refrigerator | Control system programmable logic Controller automatically adjusts the operating conditions of the refrigerator according to the test conditions, compressor return air chill down circuit, energy pressure control valve |

| refrigerant | Operating Environmentally friendly refrigerant R404a/R23 with ozone depletion index of 0 |

| Refrigeration system | Low noise air-cooled chilled down water tower (optional) |

| circulating water pump | Low noise pipeline pump powerful water supply cycle (optional) |

| Controller system | Imported Controller, Separate Control of Temperature and Humidity |

| setting method | Chinese/English interface, touch input |

| operation mode | Program method/valuation method |

| setting range | Maximum Temperature range 5 ℃ |

| Display resolution | Temperature: 0.01 ℃; Humidity: 0.1% R.H; Time: 1min; |

| Power-off memory function | The power failure recovery mode can be set as: hot start/cold start/stop |

| Temperature sensor | PT100 platinum resistor |

| Heating system | Nickel alloy heating pipe, Circulating Fan, P.I.D control heating |

| Humidification system | Humidification mode of electric boiler is adopted, the compressor starts dehumidification, and P.I.D controls the humidification amount to reach the required Humidity |

| Software Operating Environment | IBM PC compatible computer, CPU above PII, memory above 128M, Simplified Chinese Windows2000 or Simplified Chinese WindowsXP operating system |

| setting range | Temperature: Adjust according to the temperature working interval of the equipment (upper limit + 5 ℃, lower limit -5 ℃) |

| input | platinum resistance |

| subsidiary function | Fault alarm and cause, processing prompt function; power-off protection function; Upper/Lower limit temperature protection function |

| Water quality requirements | It is required to meet the second-class water quality of the national analytical laboratory, and the solid impurity content of the water is less than 1mg/L |

| Water supply method | Automatic/manual dual water supply mode |

| Water supply device | 1. The machine is equipped with a small water softener filtrate unit, which only needs to be connected to tap water, and the pure water required for automatic production spray is required to effectively prevent impurities in the water quality from adhering to the surface of the sample and affecting the test results; water supply pressure: 0.1~ 0.4Mpa; 2. PVC large water tank, manual water replenishment can be used when water supply is inconvenient |

| Refrigeration system protection device | Compressor overheating, overcurrent, overpressure, phase inversion, oil shortage protection |

| Protection device | Ultimate overtemperature, fan, motor overheating relay |

| Humidification system | Humidification heating pipe dry burning, abnormal water supply, abnormal drainage, abnormal water shortage protection |

| Power | Leakage protection, overload, short circuit and undercurrent protection |

| mode of transportation | Whole machine freight |

| Environmental temperature | 5~30℃ |

| Environmental humidity | ≤85%R.H |

HUDA QD-E708-1000K60-X10 Rapid temperature change Test Chamber Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Low/high Temperature Test Chamber LED packaging adhesive resistance to high-low temperature test scheme

- Low/high Temperature Test Chamber applied to high-low temperature resistance test of hot boiler

- Low/high Temperature Test Chamber for high-low temperature resistance test of fluoroether rubber sealing materials

- Application of low/high Temperature Test Chamber in high-low temperature resistance test of multi-arm carbon nanotubes

- Application of low/high Temperature Test Chamber in high-low temperature resistance test of rubber and plastic materials

- Low/high Temperature Test Chamber for high-low temperature resistance test of paper towels

- Low/high Temperature Test Chamber in printing circuit board test high-low temperature resistance test

- Mobile phone high-low temperature test solution

- Low/high Temperature Test Chamber for testing high-low temperature performance of high temperature resistant coatings

- Low/high Temperature Test Chamber used to test plastic parts high-low temperature performance

- ActiveISO 9022-23

- ActiveGB/T 2424.7-2024

- ActiveQJ 481-1990

- ActiveGB/T 713.1-2023

- ActiveGB/T 9979-2005

- ActiveGB/T 39933-2021

- ActiveGB/T 10590-2006

- ActiveGB/T 33861-2017

- ActiveGB/T 10592-2023

- ActiveGB/T 32065.7-2015

- ActiveGB/T 2423.63-2019

- ActiveGB/T 32710.11-2016

- ActiveGB/T 2423.4-2008

- ActiveGB/T 2423.102-2008

- AbolishGB/T 2423.34-2005

- AbolishGB/T 2423.25-2008

- ActiveGB/T 2423.1-2008

- ActiveASTM D2485-2022

QD-E708-1000K60-X10

QD-E708-1000K60-X10