CHINA Humidity Test Chamber NBCA-FB-80A

Built-in explosion-proof system, with pressure relief valve, volume 80L, effective size of inner box 400 × 500 × 400mm, temperature range -40~ + 150 ℃, 304 stainless steel material, with explosion-proof handle.

HuiTai

HuiTai-

FARI FR-1204-608 Programmable constant temperature and humidity Tester, Climate Chamber -40~150 ℃/608L

$ 7586.00 -

YIHENG BPHJS-250B High-low temperature alternating damping heat Test Chamber -40~130 ℃/250L

$ 7410.00 -

HZAOC GDJS-500C high-low temperature Humidity Cyclic Chamber -40~150 ℃/500L

$ 10112.00 -

KESIONOTS KS-HW225B High Accuracy Constant Temperature and Humidity Chamber 0~ 100 ℃/225L

$ 5313.00 -

HZAOC GDJS-250D high-low temperature Humidity Cyclic Chamber -60~150 ℃/250L

$ 9181.00

Features

This equipment is suitable for all kinds of electrical and electronic products and other products, parts and materials to carry out high-low temperature constant and gradual, damp heat test and other environmental simulation reliability tests.

Power supply conditionsand power supply

AC220V single-phase R, N + protective grounding, Voltage tolerance fluctuation range 10%;

THE ALLOWABLE FREQUENCY FLUCTUATION RANGE IS 50±0.5HZ, AND IT IS POWERED BY TN-S MODE OR TT MODE

The ground resistance of the PGD is less than 4Ω

The user is required to configure the corresponding capacity air or power switch for the equipment at the installation site, and this switch needs to be independently controlled.

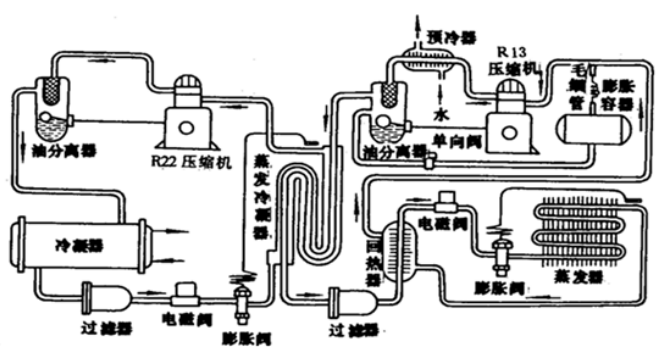

Refrigeration principle and method

Refrigeration mode: In order to ensure the cooling rate and minimum temperature requirements of the laboratory, the laboratory adopts a set of binary compound refrigeration system, the compound system includes a high-temperature refrigeration cycle and a low-temperature refrigeration cycle, and the heat exchange is realized through the evaporative condenser.

Program capacity and control functions

The number of programs that can be used: up to 120 groups, and 1 program can be composed of 1~99 segments

Usable memory capacity:1200 segments, repeatable command execution: each command can be up to 999 times, the program slope setting can be set by the timeline, the program can be set to be used in conjunction with each other, and the production of the program is simple to use in the form of dialogue

It has functions such as editing, clearing, and inserting, and 4 sets of time signal output control (can control the ON/OFF action of the DUT)

It has 9 sets of PID parameter settings, jump segment, hold function, curve display, data acquisition, date and time adjustment function, button and screen lock (LOCK) function, which can be connected to the computer for use

The implementation standards and test conditions are met

1. GB/T2423.22-2002 Test N temperature change test method

2. GB/T2423.3-93 (IEC68-2-3) Test Ca: Constant Damp Heat Test Method

3. GB/T2423.4-93 (IEC68-2-30) Test Db: Alternating Damp Heat Test Method

4. GJB150.3-86 High temperature test method

5 GJB150.4-86 Low temperature test method

6. GJB150.9-93 Damp heat test method

7. GB2423.1-2008/IEC6008-2-1-2007 Environmental Test for Electrical and Electronic Products Part 2: Test Method Test A: Low temperature

8. GB/T 2423.2-2008 Environmental test for electrical and electronic products Part 2: Test method Test B: high temperature

9. G/BT 2423.4-2008/IEC6008-2-30:2005 Alternating damp heat method

10. GB/T5170.18-2005 Electrical and Electronic Products Environmental Test Equipment Basic Parameter Verification Method Temperature/Humidity Combined Cycle Test Equipment

11. GB/T10586-2006 technical conditions for damp heat Test Chamber

12. GB/T 10589-2008 Technical conditions for low Temperature Test Chamber

Main configuration and structure

1. an outer box

(1) The outer wall of the box and door is made of good cold-rolled steel plate, with a thickness of 1.5mm, stainless steel or surface spraying.

(2) Appearance: stainless steel box or gray, blue door.

2. Inner box

(1) SUS304 stainless steel plate (including the inner side of the door), 2mm thick, the inner box insulation layer side is reinforced with an additional integral structure, and the stiffener is welded into a tic-tac-toe frame according to 300*300mm.

(2) All seams TIG continuous welding, which can prevent mildew, rust and corrosion.

3. Thermal insulation

(1) 100mm thick rigid polyurethane foam and glass wool, fireproof and fireproof, in line with environmental protection requirements.

(2) The insulation layer is designed as 70mm polyurethane foam layer + 30mm ultra-fine glass wool, which meets the requirements of low temperature insulation and high temperature resistance of 150 °C.

(3) Sealing: double-layer silicone rubber sealing strip, high temperature resistance, anti-aging, high reliability.

4. Box door

(1) Door opening method: single door, explosion-proof safety door handle design.

(2) Locking mechanism: hook type (full solid stainless steel).

(3) Explosion-proof chain: 2 Ø6mm stainless steel chains are installed on the left and right sides of the gate.

(4) Anti-condensation of door frame and door edge: The door frame and door edge are equipped with anti-condensation electric heating device to prevent external condensation and frost.

5. Observation window

(1) INSTALL ONE SET OF W260*H340MM 3-layer heating and sweatproof vacuum glass observation window on the single-opening door, which is located in the center of the gate and the observation window.

(2) Vacuum coating is treated with moisture-proof temperature insulation, anti-frosting, anti-fog and anti-condensation to ensure that the samples in the Test Chamber can be observed during the test.

(3) In the damp heat mode, the heat measurement in the observation window is started to prevent the inner layer from fogging and the product cannot be clearly observed.

6. Standard configuration

(1) Lead hole: There is 1 Φ50mm lead hole on the left side of each cavity, a total of 1, equipped with soft rubber plug and stainless steel cover.

(2) Lighting: Explosion-proof LED lighting, the control switch is located on the touch screen controller, which is easy to operate.

(3) Sample holder: The equipment is equipped with 2 layers of high-low temperature resistant SUS304 stainless steel punching partition, adjustable, detachable, and the load-bearing (uniform) ≥ 20kg/layer.

(4) Teflon treatment of the inner box and test frame, insulation, high temperature resistance, friction resistance, to prevent the battery electrodes and tabs from contacting the box from short circuit.

(5) Caers: Equipped with 4 casters and cups, 2 of which are universal wheels.

(6) One set of three-color indicator lights is installed on the top of the equipment, which can visually display the running status of the equipment.

(7) It is equipped with a buzzer, and the buzzer reminds when the equipment fails.

(8) It is equipped with an emergency stop button, which can quickly cut off the power supply of the equipment in case of emergency.

Product-related systems

1. Pressure relief port

(1) The equipment is set ≥ 250×250mm pressure relief port, and the pressure relief port will be automatically opened when the internal pressure of the box ≥ 0.104MPa.

(2) Install 2 explosion-proof chains on the left and right sides of the gate.

(3) Observe and install the grille to prevent glass breakage and sputtering.

2. Impeller:The impeller is made of aluminum impeller to prevent friction sparks from friction with the stainless steel volute after the impeller is loosened.

3. Grounding protection:The inner shell is provided with reliable grounding lines, and the surface of the equipment is sprayed with conductive anti-static paint to ensure that static electricity cannot accumulate on the surface of the equipment shell.

Air supply temperature measurement system

1. Air supply characteristics:High-precision air supply circulation mode in the box. The high temperature and high Humidity Chamber adopts the air supply mode of upper return air and lower air outlet, the air flow direction in the working room is "C" shape, and the return air outlet is designed and installed with one set of double-layer shutters, which can fine-tune the air supply direction according to the temperature distribution of the measured point of the Recorder;

2. Wind wheels:Multi-wing centrifugal circulating fan, high-low temperature resistant aluminum alloy blades.

Refrigeration system (explosion-proof constant temperature and Humidity Test Chamber temperature cycle Test Chamber configuration)

1. Working mode: air-cooled mechanical compression cascade refrigeration mode (according to Operating Conditions).

2. Refrigeration principle:In order to ensure the cooling rate and minimum temperature requirements of the laboratory, a set of binary duplex refrigeration system is adopted, which includes a high-temperature refrigeration cycle and a low-temperature refrigeration cycle, and the heat exchange is realized through the evaporative condenser.

3. Refrigeration compressor

(1) Low noise, French Taikang fully enclosed compressor.

(2) Electronic expansion valve refrigerant flow servo control technology.

(3) With energy control valve device, the compressor power can be adjusted by 10%~100%.

4. an evaporator:Finned surface cooling evaporator (doubles as a dehumidifier), the fins are placed in the channel with hydrophilic film coated aluminum sheets, which are used for heat exchange or temperature equilibration of indoor air.

5. a condenser:The air-cooled effective forced convection fin condenser has a small surface area, small energy loss and high heat exchange efficiency.

6. a throttling device:Danfoss thermostatic expansion valves. Capillary.

7. Oil separator:Emerson, the refrigerated oil droplets mixed with the high-temperature and high-pressure refrigerant gas discharged from the compressor are separated and returned to the compressor curved rail cavity for compressor lubrication and cooling.

8. Refrigerator control mode:The PLC (Programmable Logic Controller) of the control system automatically adjusts the operating conditions of the chiller according to the test conditions.

9. Defrosting function:The refrigeration system is equipped with 1 set of automatic defrosting system, which can effectively avoid the temperature rise caused by frosting of the evaporator due to poor sealing.

Heating and humidification system (when required)

1. Heater

(1) Heater: The flake heating tube is selected, and the heater is sensitive and conducive to preventing temperature overshoot.

(2) The output signal of the controller realizes high-precision non-contact switch control through the Swiss Carlo SSR solid state relay.

2. Humidifier (only for the damp heat type)

(1) External boiler humidification method, install stainless steel armored electric heating tube.

(2) Heater control mode: no contact equal periodic pulse width, SSR (solid state relay).

(3) Water level control device, heater anti-dry burning device, humidifier over-temperature protection device, which can be linked with equipment alarm.

3. Humidification water (only for damp heat type)

(1) Water replenishment method: automatic water replenishment, the rear of the Test Chamber is left with an external water inlet, equipped with an automatic water inlet solenoid valve and a water level sensor, to achieve automatic water replenishment of the Test Chamber.

(2) Equipped with a 100-gallon RO water purifier, the tap water is humidified and softened, and the deionization circulation filtration system is carried out, and there are drainage holes at the bottom of the Test Chamber to eliminate the water in the Test Chamber, and the softened water meets the requirements of GJB150.1A.

Electrical control system

1. Controller

(1) Touch controller, respectively control temperature and humidity, true color LCD display, capacitive touch screen controller, high control accuracy, sensitive response, easy to use and other advantages.

(2) The button and screen have a lock function, and the controller operation interface has multiple password protection, and different password protection has different operation permissions to avoid human error.

(3) Real-time display of set temperature, measured temperature, number of cycles, total running time, running program number, running program name, program section number, remaining time and other information.

(4) The controller self-diagnoses and determines the fault and displays it.

2. Display: 7.0 inch TFT color LCD display.

3. Operation mode:Procedure method, valuation method.

4. Setting method:Chinese menu, touch screen input.

5. Program capacity:

(1) 100 groups of program storage capacity, each group of up to 100 segments, the longest time of segment operation: 99 hours and 59 minutes.

(2) The program can be cycled, full cycle, up to 999 times, partial cycle, up to 99 times.

(3) The fixed value operation can be set ≥ 1000000h.

6. Display resolution

(1) Temperature 0.1°C, time 0.01 minutes.

(2) Humidity 0.1%RH (if the device has humidity function).

7. Data recording: built-in recording program, the memory in the controller can be stored for 24H for 300 days (the recording frequency is adjustable), which can be convenient to automatically generate temperature and humidity curve files and transfer them to XLS tables.

8. Communication function

(1) 232/USB interface, with local and remote communication functions, the cumulative length of the cable is up to 800m.

(2) PC software Operating Environment: IBMPC compatible machine, PII. or above CPU, 128M memory, Chinese Simplified or Chinese Simplified Windows XP operating system.

9. Control mode

(1) Anti-integral saturated PID.

(2) BTHC (Temperature and Humidity Test Equipment).

10. Curve recording function: SRAM with battery protection can save the set value, sampling value and sampling time of the device, and can slide to observe the data in real time by touching the finger on the screen.

11. Ancillary functions: fault alarm and cause, processing prompt function, power-off protection function, upper and lower limit temperature protection function, timing function (automatic start and automatic stop operation), self-diagnosis function.

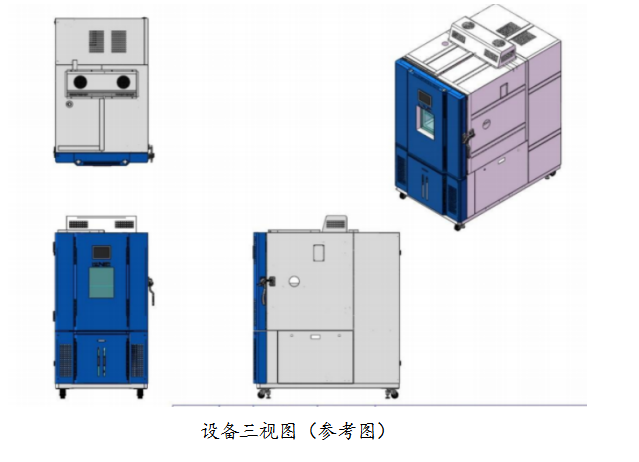

Product structure diagram

Safety and environmental protection requirements

Refrigeration system

(1) Compressor overpressure

(2)The compressor motor is overheating

(3)The compressor motor is overcurrent

(4)Condensing fan overcurrent protection

(5)Compressor oil pressure underpressure protection

Humidification system

(1)Dry boil the heating tube

(2)The water supply is abnormal

(3)Abnormal drainage

Laboratory

(1)Adjustable over-temperature protection --- over-temperature protection mode 1

(2)The ultimate over-temperature --- over-temperature protection mode of the air conditioning channel 2

(3)The controller sets the over-temperature shutdown alarm --- over-temperature protection mode 3

(4)Fan motor overheating protection

Power supply system

(1) Power supply under-inverse protection, leakage, short circuit, over-Voltage, under-Voltage protection

(2)System over-current and under-Voltage protection

(3)Control loop current limit protection

(4)The controller self-diagnoses and determines the fault display

(5)Fuseless short-circuit circuit breaker protection switch

(6)Load short-circuit protection

(7)Safety grounding terminals

(8)The electromagnetic shielding device is sealed to prevent electromagnetic leakage

HuiTai NBCA-FB-80A Humidity Test ChamberSpecifications

| LIST | VALUE |

|---|---|

| Interior Volume | 80L |

| Temperature range | -40~+150℃ |

| temperature resolution | 0.01℃ |

| Temperature fluctuation | ±0.5℃ |

| Temperature Uniformity | ≤2℃ |

| Humidity control range | 20~98%RH |

| Humidity Deviation | ±1.5℃ |

| Humidity resolution | 0.1% RH |

| Humidity Deviation | ±2% RH |

| Humidity Uniformity | ≤3% RH |

| Humidity fluctuation | ±2% RH |

| Weight | 150㎏ |

| Maximum power | 5KW |

| Maximum current | 20A |

| Allowable frequency fluctuation range | 50 ± 0.5HZ |

| Power Supply | TN-S mode Power or TT mode Power |

| Allowable Voltage fluctuation range | 10% |

| Operating Conditions | The environment temperature is + 25 ℃, the Relative Humidity ≤ 85%, and the value measured under the condition that there is no sample in the test chamber. |

| Inner box material | 304 #stainless steel 1.2mm thick |

| Enclosure Material | 304 #stainless steel 1.0mm thick or (Cold rolled steel plate 1.2mm thick paint treatment, optional) |

| Thermal insulation material | Polyurethane Styrofoam 100mm thick |

| Lead test hole | Open the test hole of Φ50mm, and attach the corresponding thermal insulation accessories and special sealing soft plugs |

| Viewing Window | Transparent Electric Heating Film Hollow Tempered Glass (on the door) (with anti-condensation function), size 230X270mm |

| Control Panel | TEMI880 LCD touch programmable Controller, lighting switch, main power switch, RS-232 communication interface |

| Machinery room | Refrigeration unit, exhaust fan, drainage device, adjustable back leaf window, water vapor outlet |

| Test material rack | It is punched and bent into a mesh with 304 #stainless steel, which is easy to use, the spacing between the material racks can be adjusted, and the standard configuration is two pieces. |

| Distribution control cabinet | Total power circuit breaker, Controller, switchboard, cooling fan, over-temperature protector |

| Heating system | Using scale heat dissipation heating tube P.I.D to control heating to achieve temperature equilibrating |

| Humidification and dehumidification system | Adopt external humidification method, the compressor starts dehumidification, and P.I.D controls the humidification amount to reach the required humidity |

| hydration system | Self-made PVC enlarged water tank, water pump to enhance automatic water supply, circulating filtrate recovery |

| Refrigeration compressor | Adopt French Taikang fully enclosed compressor imported from Europe |

| Evaporator | finned tube heat exchanger |

| Evaporative condenser | The plate heat exchanger brazed by high temperature copper has small surface area, small energy loss and high heat exchange efficiency |

| Throttle device | Thermal expansion valve, capillary |

| Oil separator | Separate the refrigerated oil droplets mixed with the high temperature and high pressure refrigerant gas discharged from the compressor, and return them to the compressor curved rail cavity for compressor lubrication and cooling |

| refrigerant | The environmental protection refrigerant R404A/R23 is used as the refrigeration medium of this refrigeration system |

| Operation mode | Program method/fixed value method |

| Setup method | Chinese/English interface, touch input |

| Set range | Maximum temperature range Upper and lower limits 5 ℃ |

| Power-off memory function | The power-off recovery mode can be set as: hot start/cold start/stop |

| Boot reservation function | You can set the boot time at will, and the machine will run automatically after turning on the Power . |

| Curve recording | RAM with battery protection to save device settings, sampling values and sampling time; maximum recording time is 60 days |

| Software Operating Environment | IBM PC compatible machine, CPU above PII, memory above 128M, Simplified Chinese Windows2000 or Simplified Chinese WindowsXP operating system |

| Circulating Fan | Low noise multi-wing centrifugal fan |

| heater | Imported nickel-chromium alloy electric heater |

| Heater control method | No touchpoint equal period pulse width modulation, SSR (solid state relay) |

| humidifier | Imported nickel-chromium alloy electric heater; external humidification method |

| Water supply method | Pump lift |

| Water supply device | Large water tank |

| Water quality requirements | Resistivity ≥ 500Ω · m |

| Refrigeration system | Compressor overheating, overcurrent, overpressure, condenser overheating |

| test chamber | Ultimate overtemperature, fan, motor overheating relay |

| Humidification system | Humidification heat pipe dry burning, abnormal water supply, abnormal drainage, abnormal water shortage |

| Power | Leakage protection, overload and short circuit protection |

| Storage environment requirements | Equipment environment temperature should be kept within 0 ℃~ + 35 ℃ |

| Mode of transportation | Complete-built unit shipping |

HuiTai NBCA-FB-80A Humidity Test Chamber Packing list

Complete-built unit x1, manual x1, certificate x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- The Critical Study of Coating Specimen State Adjustment and Test Temperature Humidity

- Principle and application analysis of constant temperature and humidity Test Chamber

- Principle and Application Analysis of Fluorine Resin thermostatic Box

- Analytical magnetic material programmable Humidity Chamber, principle, application and selection

- Principle, application and selection of luggage Humidity Chamber

- Principle, application and selection of programmable Humidity Chamber for die casting

- ActiveJJF 1564-2016

- ActiveJJF 1270-2010

- ActiveJJF 1101-2019

- 2058-2023

- ActiveGB/T 43489-2023

- ActiveGB/T 38948-2020

- AbolishGB/T 2424.5-2006

- AbolishGB/T 2423.34-2012

- ActiveGB/T 2423.50-2012

- ActiveGB/T 32368-2015

- ActiveGB/T 5170.2-2017

NBCA-FB-80A

NBCA-FB-80A