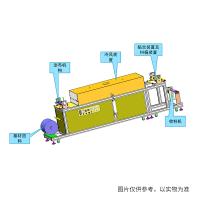

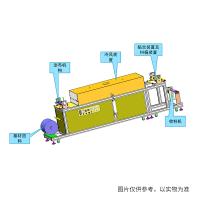

CHINA TBJ-JCRL-DJ2 Water-cooled Air-cooled Miniature Coil Applicator

Adjustable scraper Applicator, suitable for Applicator (composite) test of drum-based substrates, Application width 22mm, 25mm, using stainless steel electric heating tube heating.

zy

zy-

Factory Direct Rva - 0.5/300 Pro Roll to Roll Micro Concave Film Applicator Desktop Precision Spreader Test Line

$ 23752.00 -

Air-cooled curing coil Film Applicator Rgd-01/300cl Tape unwinding + scraping + air-cooled curing + overlay deviation correction + winding function

$ 34803.00 -

CHINA Rxf-01/350 pro PET slot die Film Applicator Spreader Width 350mm

$ 47432.00 -

CHINA Small hot-melt adhesive Continuous Film Applicator NBC-6025 Continuous Coater

$ 4176.00 -

Rgd-00/400cs hot-melt adhesive coating and cutting machine, Coil Automatic Film Applicator

$ 36382.00

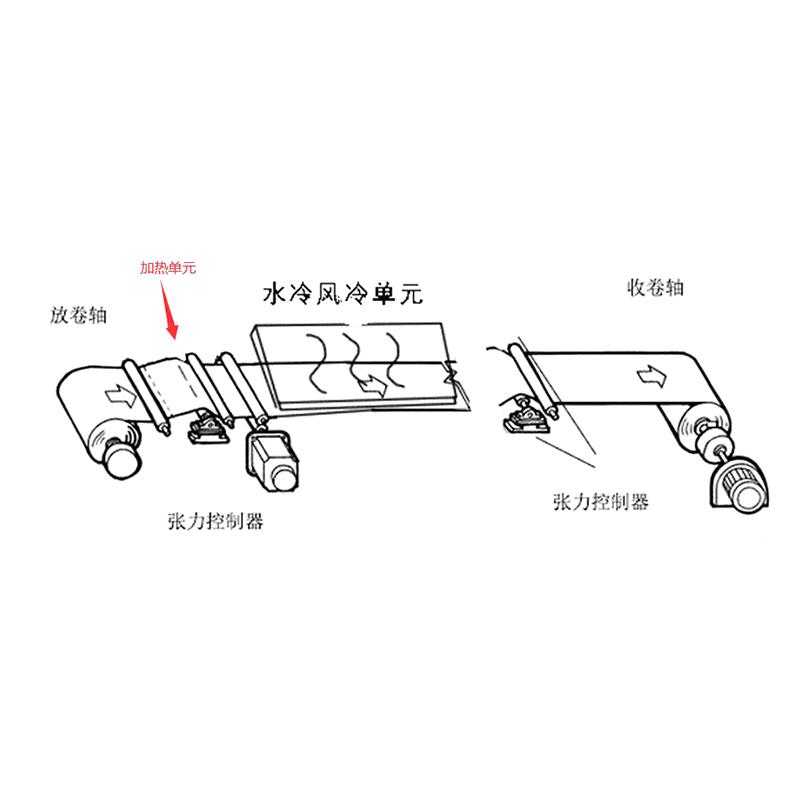

main part configuration

(1 ) Unwinding unit

Type: single station

Effective unwinding width: 100mm

Effective unwinding diameter: ≤φ400mm (adjustable)

Unwinding shaft: Inflatable shaft

Unwinding tension control: tension controller automatic control,

( 2 ) Coating unit

Coating method: adjustable doctor blade coating

Scraper material: 304 stainless steel

Coating width: 22mm, 25mm

Coating thickness: 0-10mm

Coating adjustment: dial gauge adjustment

Coating accuracy: ±0.02mm

Coating tray: 304 stainless steel

( 3 ) Feeding and melting unit

Type: resistance wire cylinder heating

Capacity: 1L (removable)

Material: Stainless steel

Temperature: Room temperature~200℃±3℃

Temperature control: digital display temperature control meter automatic proportional temperature control

( 4 ) Winding unit

Type: single station

Effective winding width: 100mm

Effective winding diameter: ≤φ400mm (adjustable)

Rewinding shaft: Inflatable shaft

Winding tension control: automatic control by tension controller

(5) Air-cooled water-cooled unit

Water cooling tank size: 500*150*100mm

Number of air cooling fans: 4 220V 50HZ

zy TBJ-JCRL-DJ2 Water Cooled Air Cooled Mini Coil SpreaderSpecifications

| LIST | VALUE |

|---|---|

| Application mode | Adjustable Application |

| Effective Application Width | 0-25mm |

| Application rate | 5-25m/min |

| Host Power | 220V 50Hz |

| Dimensions | ≈1200mmX600mmX750mm |

| Unwinding diameter | ≤ 400mm |

| winding diameter | ≤ 400mm |

| Heating method | Stainless steel electric heating tube heating |

| temperature control | Room temperature~ 250 ℃ ± 3 ℃ |

| Unwinding Unit - Type | Single station |

| Unwinding Unit - Effective Unwinding Width | 100mm |

| Unwinding Unit - Effective Unwinding Diameter | ≤ Φ400mm (adjustable) |

| Unwinding Unit - Unwinding Reel | Inflatable shaft |

| Unwinding Unit - Unwinding Tension Control | Tension Controller automatic control |

| Application Unit - Application Mode | Adjustable Application |

| Application Unit - Scraper Material | 304 stainless steel |

| Application Unit - Application Width | 22mm、25mm |

| Application Unit - Application Film thickness | 0-10mm |

| Application Unit - Application Adjustment | Dilometer adjustment |

| Application Unit - Application Precision | ±0.02mm |

| Application Unit - Coating Tray | 304 stainless steel |

| Feeding Melting Unit - Type | Resistance wire cylinder heating |

| Feed melting unit - Capacity | 1L (removable) |

| Feed melting unit - material | stainless steel |

| Feed melting unit - temperature | Room temperature~ 200 ℃ ± 3 ℃ |

| Feed melting unit - temperature control | Digital temperature control meter automatic proportional temperature control |

| Winding Unit - Type | Single station |

| Winding Unit - Effective Winding Width | 100mm |

| Winding Unit - Effective Winding Diameter | ≤ Φ400mm (adjustable) |

| Winding Unit - Winding Reel | Inflatable shaft |

| Winding Unit - Winding Tension Control | Tension Controller automatic control |

| Air-cooled water cooling unit - water cooling tank size | 500*150*100mm |

| Air Cooled Water Cooled Units - Number of Air Cooled Fans | 4个 220V 50HZ |

zy TBJ-JCRL-DJ2 Water Cooled Air Cooled Mini Coil Spreader Packing list

Host x1, scraper 22mmx1, scraper 25mmx1, heating unit component x1, winding unit x1, unwinding unit x1, water cooling unit x1, air cooling unit x1, manual x1,

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Film Applicators in Resin Moulding

- Comparison of Different Spreader Methods of Small Coating coater

- Systematic understanding of coil isolation film coater

- Technical Analysis and Troubleshooting of Coiled Coil Coater

- Application of Coil Coater Spreader on Non-woven Fabric

- Selection and use skills of thermosetting material coater

- Comparative Analysis of Small Spreader and Traditional Roll-to-Roll Coater

- In-depth analysis of small coil coater technology and selection points

- Application and Advantages of Coater in Antipyretic Sticker prepative

- Analysis of extrusion hot-melt adhesive coater technology and comparative study of coil hot-melt adhesive coater

TBJ-JCRL-DJ2

TBJ-JCRL-DJ2