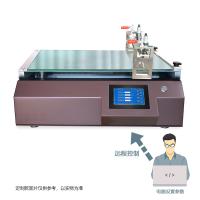

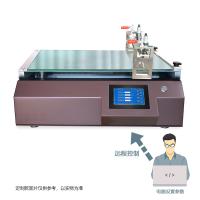

China TBJ-FJLZ-DJ1 Unwinding Film Applicator bar + Vacuum chuck + automatic feeding

Customized model, unwinding + automatic feeding + bar + Vacuum chuck, effective coating area: 400mm * 600mm, Vacuum chuck area: 400mm * 600mm

zy

zy-

Chinese removable scraper heating vacuum adsorption Automatic Film Applicator TBJ-X5-DJ6 scraper material 316 stainless steel

$ 4334.00 -

CHINA TBJ-A1-DJ9 Floor type wire-rod Film Applicator Coating size 600 * 800mm

$ 6387.00 -

HUINUO TM 2100/01 drawdown blade heating Coater coating format 400 * 400mm

$ 4018.00 -

China Intelligent program-controlled drawdown Bar & blade Film Applicator TBJ-B2-DJ7 Coating size 300 * 450mm

$ 5124.00 -

HuiNuo TM3300Pro/32 drawdown Bar & Blade Heating Vacuum chuck Coater Automatic Film Applicator 150 * 30cm

Login

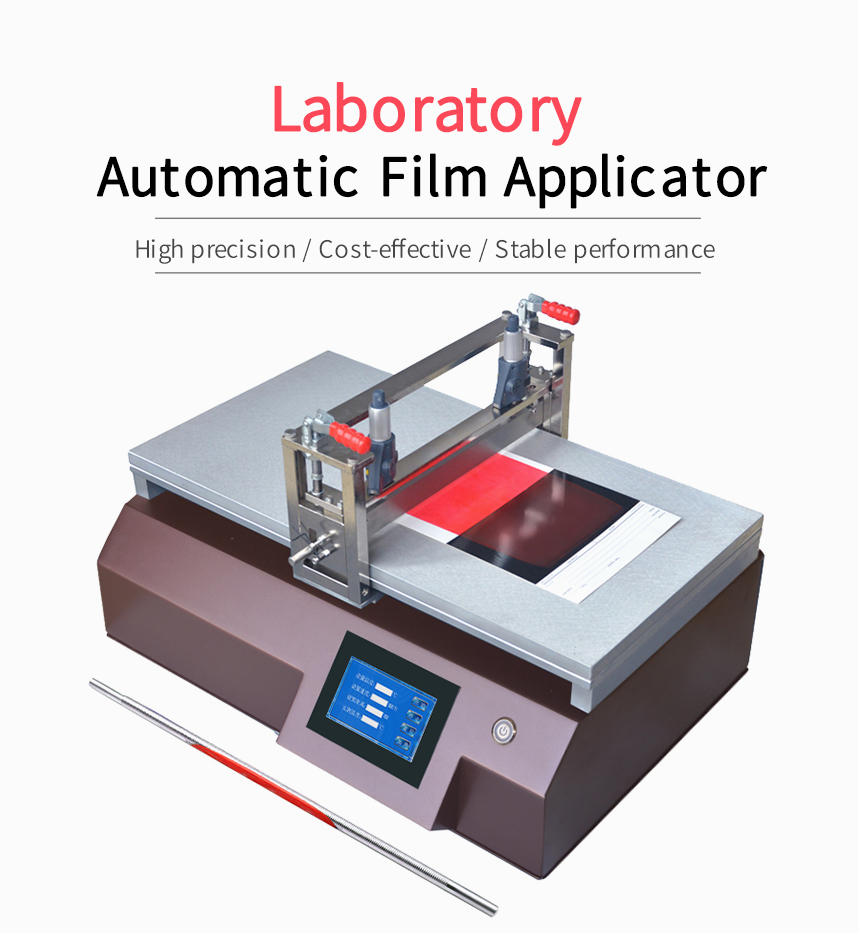

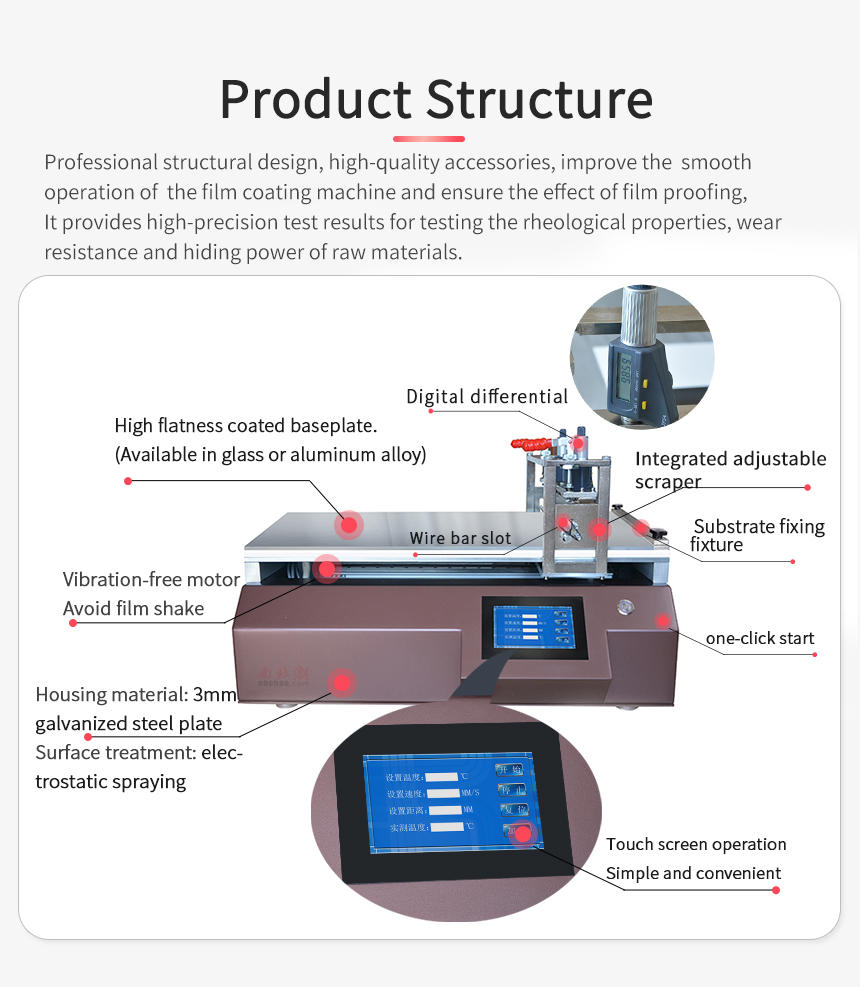

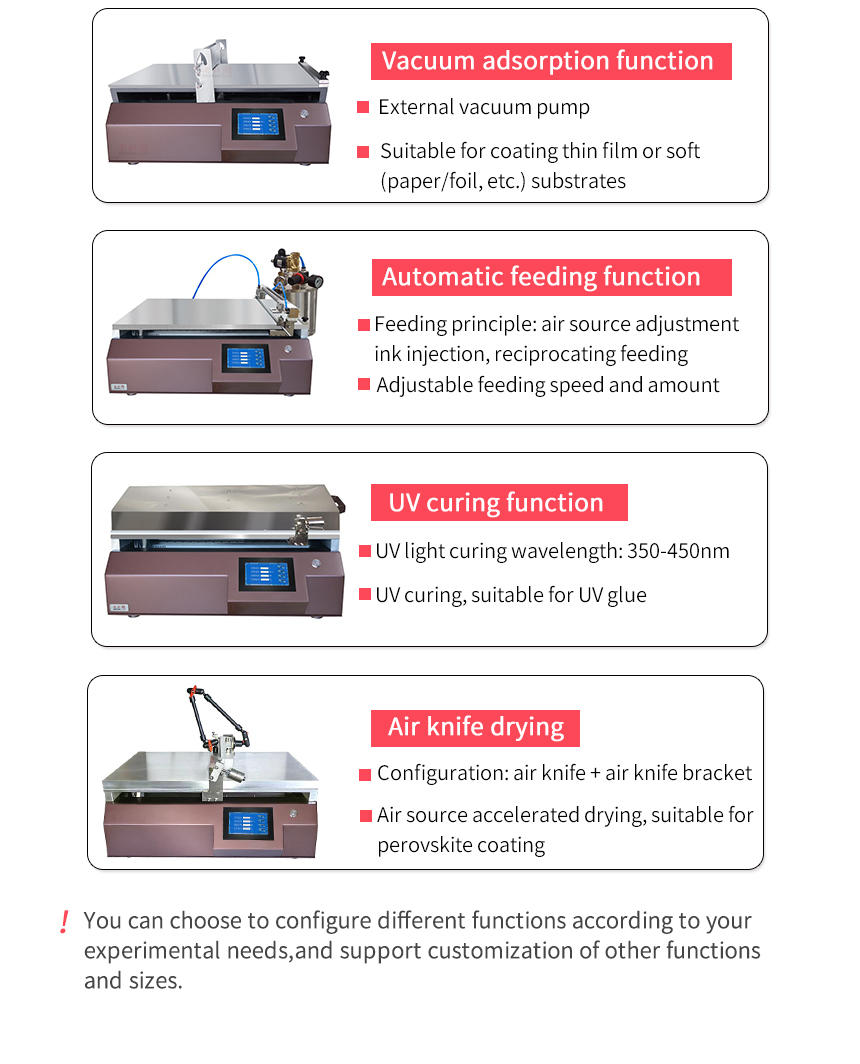

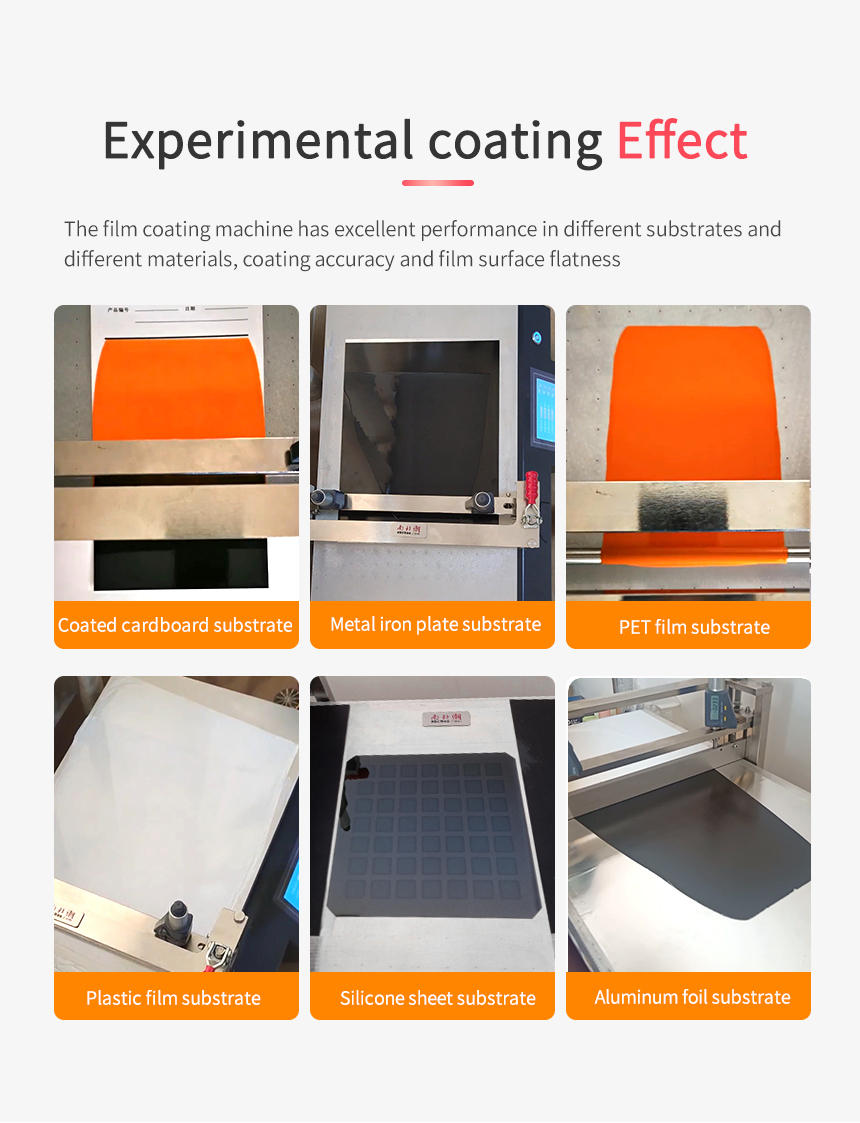

TBJ-FJLZ-DJ1 unwinding type film coating machine all adopts imported parts, and the price is excellent and low. It has been favored by many R&D institutions of multinational enterprises, many familiar universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure to ensure the effect of coating and glue, to ensure the uniformity and stability of coating and glue. It has the functions of unwinding, automatic feeding, wire rod and vacuum adsorption, and has a larger coating area than ordinary models.

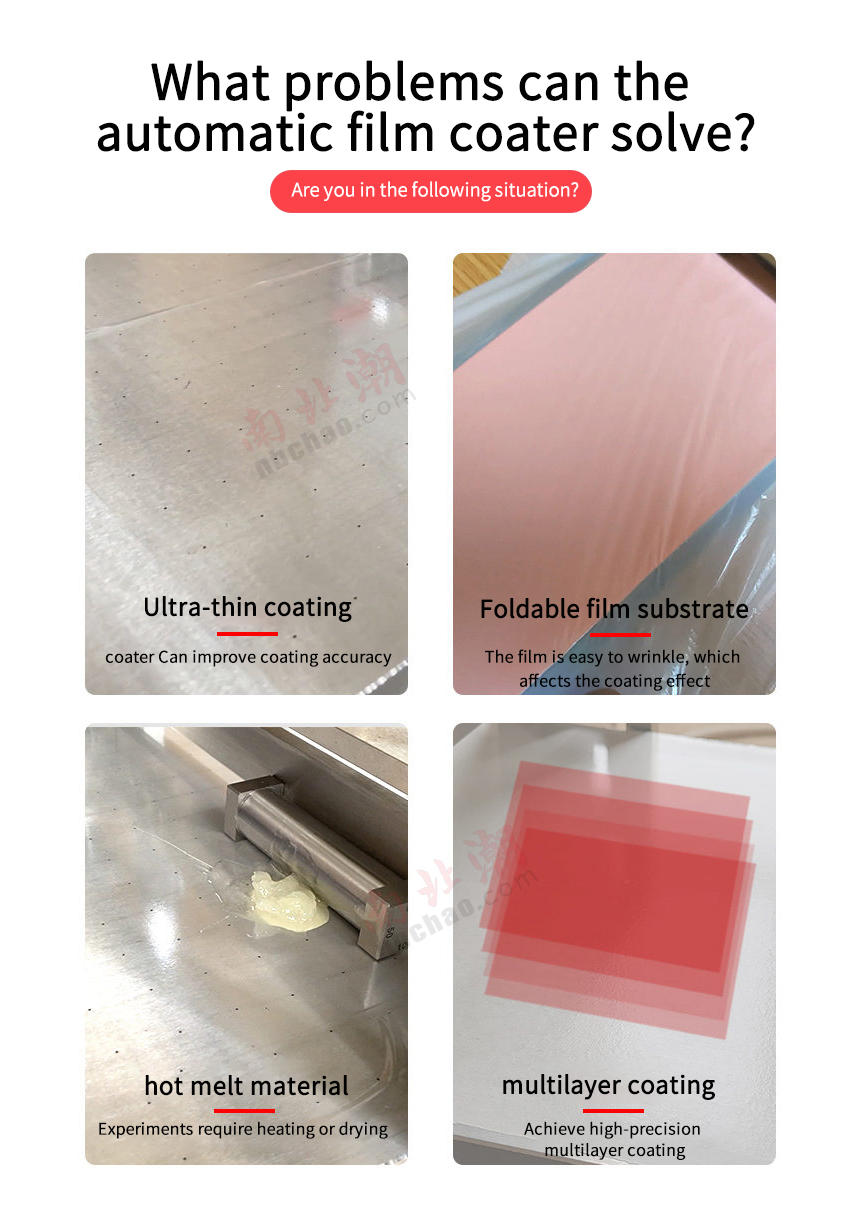

Since the main factors affecting the coating film are the coating speed and the pressure applied on the Film Applicator, etc., the coatings painted manually are often inconsistent, especially the differences between different people are even greater, which is why This makes it difficult to compare test results between samples.

Optional

zy TBJ-FJLZ-DJ1 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Coating size | 400mm*600mm |

| Spreader speed | Digital display, different speeds |

| Vacuum Area | 400 * 600Mm (can be customized) |

| Vacuum aperture | Φ1.2mm |

| Vacuum hole spacing | 20* 20mm |

| Vacuum pump size | 380*180*280mm |

| speed control | Infinitely variable speed |

| Coating table material | aluminum alloy |

| Wire bar Accuracy | ±1μm |

| Customizable function | Automatic inking system |

| Feeding principle | Air source pressure flows out |

| Feed Sport Mode | Reciprocating linear motion |

| Feeding back and forth traverse speed | 2-150mm/s |

| spit Volume | Adjustable (by adjusting the air pressure and the operating speed of the discharge port) |

| Shaft drive mode | Timer belt |

| Feeding system air source | 0.6Mpa, can be connected to the trachea of φ 8 (self-matching) |

| Power Voltage of feeding system | 220V,50Hz |

| Tank pressure | Maximum withstand 8Mpa |

| Material of feeding barrel | 304 stainless steel with a wall thickness of 4mm |

| Feeding drum configuration | Safety valve, pressure regulating valve, pressure gauge, relief valve |

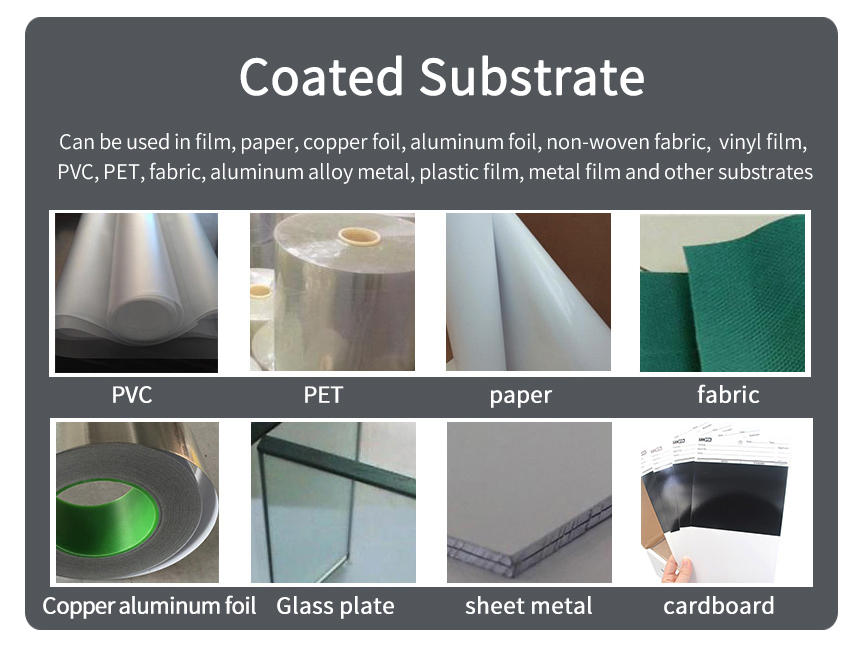

| Optional | Leakage tank, substrate fixing fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

| Feeding drum Volume | 1L |

| Dimensions | 1000Mm * 600mm * 800mm (reference is subject to actual customization) |

| Unwinding bracket | manual unwinding |

zy TBJ-FJLZ-DJ1 Automatic Film Applicator Packing list

Film Applicator X1, imported bar L500 long X2, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of Vacuum adsorption Spreader Technique in Preparative Fluorescence Film on Release Membrane

- Application of laboratory coater on release paper with glue [video demonstration]

- Comparison of Different Spreader Methods of Small Coating coater

- The Film Applicator You Think Is Not What You Think

- Comparison and Difference Between Offset Press and Film Applicator

- Paper coater technology and workflow

- Tape laboratory coater technology and film accuracy optimization elements analysis

- Analysis and Application of Small Vacuum Silicone Oil Film Applicator

- Application technology and optimization of wire-rod Film Applicator on non-woven fabric

- Spraying defects and treatment methods

TBJ-FJLZ-DJ1

TBJ-FJLZ-DJ1