CHINA high-low temperature Humidity Cyclic Chamber Humidity Test Chamber -20~150 ℃/408L

Temperature control -20 ℃~ 150 ℃, volume 408L, 304 stainless steel inner box, chilled down compressor imported from France, control system imported from South Korea, multiple sets of PID control functions.

HuiTai

HuiTai-

YIHENG BPHS-120C Temperature Humidity Test Chamber -60~130 ℃/120L

$ 6832.00 -

KESIONOTS KS-HW800F ultra-low temperature humidity chamber -60~ 150 ℃/800L

$ 8313.00 -

HUDA laboratory Humidity Chamber QT-E702-150K40 -40 ℃/150L

$ 2634.00 -

CHINA NBC-100L-60 Experimental high-low temperature heating and Humidity Chamber, paint panel Thermostatic Chamber -60 ℃/100L

$ 3245.00 -

Lugong ST-800LB Humidity Chamber temperature control humidity testing machine -40 ℃~ + 150 ℃

$ 5092.00

Introduction

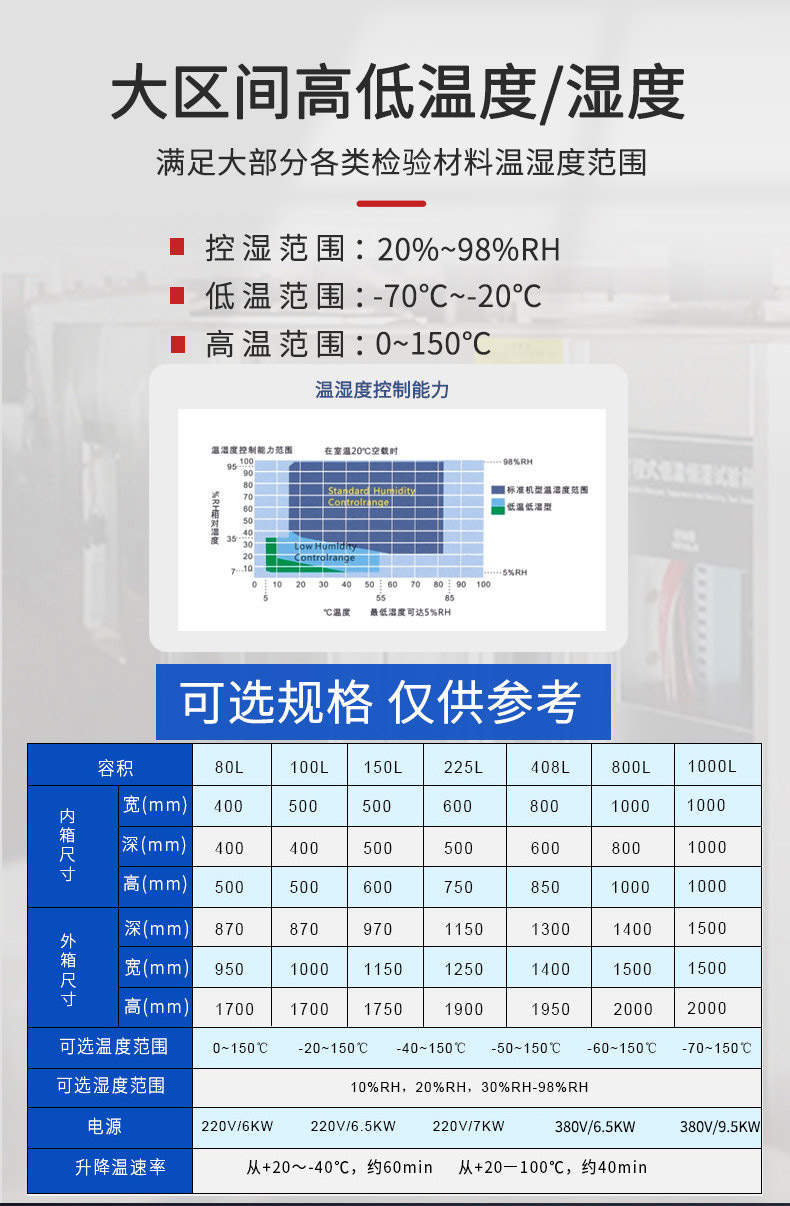

The function of the Test Chamber is to provide a test environment such as constant high-low temperature humidity and alternating high-low temperature humidity; Including refrigeration system, heating system, humidification/water system, air duct system, control system, system protection device, etc.

Constant temperature and humidity testing machine, also known as environmental testing machine, can accurately simulate low temperature, high temperature, high temperature and high humidity, low temperature and low humidity and other complex natural environments, suitable for electronics, electrical appliances, batteries, plastics, food, paper products, vehicles, metals, chemicals, building materials, research institutes, inspection and quarantine bureaus, universities and other industry units for quality control testing.

Test chamber body

1. Structural form

The integral structure, that is, the Test Chamber, the refrigeration system, the heating/humidification system, the air conditioning system, the electrical control cabinet, and the refrigeration unit are a whole, the refrigeration unit is located at the bottom of the box, and the electrical control part is placed on the side of the Test Chamber for easy operation.

2. a box

a) In the air duct mezzanine at one end of the studio, heat/humidifier, refrigeration evaporator, blower motor, fan blade and other devices are distributed; b) The Test Chamber workshop is made of 1mm thick SUS304 stainless steel plate, and enclosure is made of 1mm thick stainless steel.

Meet the criteria

GB11158、GB10589-89、GB10592-89、GB/T10586-89、GB/T2423.1-2001、GB/T2423.2-2001、GB/T2423.3-93、GB/T2423.4-93、GB/T2423.22-2001、IEC60068-2-1.1990、IEC60068-2-2.1974、GJB150.3、GJB150.4、GJB150.9等标准.

Test chamber refrigeration system

Refrigeration principle

The refrigeration part is the main part of the cold source generated by the equipment, which provides the required cooling capacity for the cooling, low temperature and constant temperature of the equipment, and the refrigeration system is automatically turned on according to the different test states of the equipment to provide cooling capacity for the corresponding test process, so as to achieve the purpose of the performance indicators of the equipment.

Refrigeration system components

1. Compressor:The refrigeration system is mainly a compressor, this scheme we use the French Taikang fully enclosed compressor, 2.2, oil separator: whether the compressor has refrigeration oil, will directly affect its life

3. Condensing evaporator:Adopting the Swedish "Alfa Laval" currently in the world

4. Vibration reduction:Compressor spring vibration reduction is adopted, and the overall secondary vibration reduction of the refrigeration system is adopted;

5. Refrigeration evaporator:The evaporator is located in the air duct interlayer at one end of the Test Chamber and is forced to ventilate by a blower motor

Touch controllers

1. LCD touch panel, screen intercom input data, temperature and humidity can be programmed at the same time

2. It can display the curve, display the set value curve, and the actual running curve;

3. Programmable, program group up to 120 groups;

4. The interface between Chinese and English can be converted;

5. It has the function of date and time adjustment, scheduled start, shutdown and screen lock.

HuiTai NBC-HW-408A Humidity Test ChamberSpecifications

| LIST | VALUE |

|---|---|

| Temperature range | -20~150℃ |

| temperature resolution | ≤2℃ |

| Temperature fluctuation | ±0.5℃ |

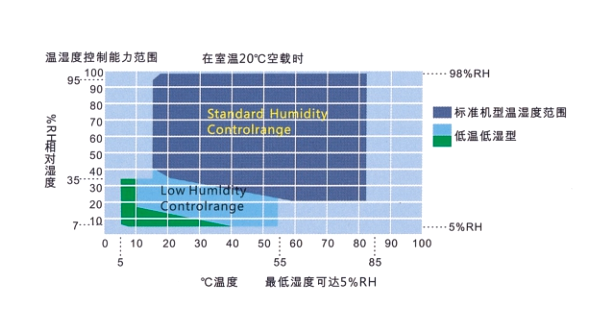

| Humidity control range | 20~98%R.H |

| Humidity Deviation | ≤3% |

| Interior size | 800*850*600mm |

| Interior Volume | 408L |

| Heating rate | RT + → 150 ℃ │ 40min (no-load nonlinear) |

| Cooling rate | RT +~ -20 ℃ │ 605min (no-load nonlinear) |

| Humidity fluctuation | ±3%R.H |

| Inner box material | SUS304 stainless steel |

| Enclosure Material | Stainless steel plate atomized (SUS #304) or cold plate paint (optional) |

| Thermal insulation material | Rigid Polyurethane Foam and Glass Cotton |

| Circulatory system | (1) 90W motor 1 (2) Stainless steel extended shaft (3) Multi-wing fan blade (SIRCCO FAN) |

| Box door | Single door, single window, left open, handle on the right |

| Box door window | 260X340x40mm 3-layer vacuum layer |

| Box door back button | SUS # 304 |

| Refrigeration system | Fully dense compressor imported from France |

| refrigerant | Environmentally friendly refrigerant R404A |

| Condenser | Fin type with cooling motor |

| Condenser | Fin type multi-stage automatic load Capacity adjustment |

| expansion system | Capacity Controlled Refrigeration System |

| Environment temperature | 0~35℃ |

| Environment temperature | 5~35℃ |

| Environment humidity | Not more than 85% |

| atmospheric pressure | 86106Kpa |

| Power | Single-phase electricity 6.5KW 380V 50HZ |

HuiTai NBC-HW-408A Humidity Test Chamber Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle, Structure and Application of Humidity Chamber

- Damp heat testing chamber FAQ and solutions

- The Critical Study of Coating Specimen State Adjustment and Test Temperature Humidity

- Damp heat testing chamber and low-Temperature Test Chamber

- Principle and Application Analysis of Fluorine Resin thermostatic Box

- Analytical magnetic material programmable Humidity Chamber, principle, application and selection

- Principle, application and selection of luggage Humidity Chamber

- Principle, application and selection of field effect transistor programmable Humidity Chamber

- Principle, application and selection of programmable Humidity Chamber for die casting

- Humidity cabinet test equipment

- ActiveJJF 1564-2016

- ActiveJJF 1270-2010

- ActiveJJF 1101-2019

- 2058-2023

- ActiveJG/T 25-2017

- ActiveGB/T 43489-2023

- ActiveGB/T 23711.2-2019

- AbolishGB/T 2424.5-2006

- AbolishGB/T 2423.34-2012

- ActiveGB/T 2423.50-2012

- ActiveGB/T 15905-1995

- ActiveGB/T 32368-2015

- ActiveGB/T 35489-2017

NBC-HW-408A

NBC-HW-408A