Defelsko posiTector200 B Standard 200B1-E Ultrasonic Thickness Gauge Wood/Plastic coating thickness measurement

Non-metallic Coating thickness measurement, such as wood, plastic and polymer Coating thickness, range 13~ 1000μm, accuracy up to 3% H +/- 2μm; support for screenshot saving; touch screen; traceable to NIST verification certificate.

-

MODERNER JM-V abrasion instrument (film configuration) is suitable for wear performance testing of Coating, paper, plastic, Spinning & weaving products

Login -

Positector SmartLink wireless connector, a new generation of detection methods

$ 695.00 -

IWAVE WG60 Glossmeter 60 ° inks paints, wood, marble, granite, ceramics, plastics, paper, etc

$ 274.00

Overview

Defelsko ultrasonic Thickness Gauges are available in both standard and advanced versions, and are available for polymer coating and thick coating applications. The Defelsko B Standard 200B1-E ultrasonic Thickness Gauge is used to measure the thickness of polymer coatings on wood, plastic and other surfaces using ultrasonic Thickness Gauge technology, and the measurement range is larger than that of general coating Thickness Gauges, and the measurement accuracy is high. The positector 200B ultrasonic Thickness Gauge is a standard ultrasonic Thickness Gauge that can store up to 250 pieces of data.

Technical parameters of precision ultrasonic coating Thickness Gauge

Applications: polymer coatings, wood, plastics, etc

Range: 13-1000 microns (0.5-40 mils)

Model: B Standard 200B1-E

Standard model features:

Measure the total thickness of the coating system

Semi-projection technology monochrome display for improved visualization in sunlight

Stores 250 readings - can be viewed or downloaded

Why Choose Defelsko's Ultrasonic Coating Thickness Gauge?

A Thickness Gauge that's built to last

Resistant to solvents, acids, oils, water and dust - all-weather protection

The rubber sheath with belt buckle provides shock absorption and protection

The host and probe of the ultrasonic precision ultrasonic coating Thickness Gauge are guaranteed for two years

Portable and easy, it is easy to meet customers

Ready-to-use – no calibration adjustment is required for the vast majority of tests

One-handed operation menu

The two-color indicator light still performs well in noisy environments

The RESET restart feature allows for a quick factory reset

Accurate measurement, the American Defesko brand is well-known in the industry

Ultrasonic precision ultrasonic coating Thickness Gauges are traceable to NIST calibration proofs

Sensitive sensors provide fast, accurate readings

Proven non-destructive ultrasonic thickness gauging technology meets ASTM D6132

and ISO 2808 standards

More about the use of Thickness Gauges: This model is powerful and easy to read

The PosiTector mainframe is extremely versatile, with PosiTector 200, 6000, SPG, DPM, and UTG probes all available and easy to replace. This transforms into a surface profiler, dew point gauge or ultrasonic wall Thickness Gauge.

Mil/micron units can be freely switched to multiple languages

The high-contrast backlit display makes it easy to operate the inverted display function in bright or dim environments, making it easy to flip the readings and operate during measurements

Use alkaline batteries or rechargeable batteries (built-in charger)

Powerful performance – trusted authentication, easy to align

Precision Ultrasonic Coating Thickness Gauges continuously display/update averages, standard deviations, min/max thicknesses, and number of readings

Screenshots - Record and store screen images for easy archiving and browsing

Quickly connect to your computer via the USB port for continuous power supply. USB cable is included

PosiSoft USB Driver - Use a regular PC/Mac browser or explorer to access stored readings and charts without the need for software

Each stored data is marked with a date and time

Update your software over the Internet to get your precision ultrasonic coating Thickness Gauge in pass

One-year quality assurance, more assured and more professional

Precision Ultrasonic Coating Thickness Gauge Features of the Standard Type

Standard model

Includes all of the aforementioned features plus...

Measure the total thickness of the coating system

Semi-projection technology monochrome display for improved visualization in sunlight

Stores 250 readings - can be viewed or downloaded

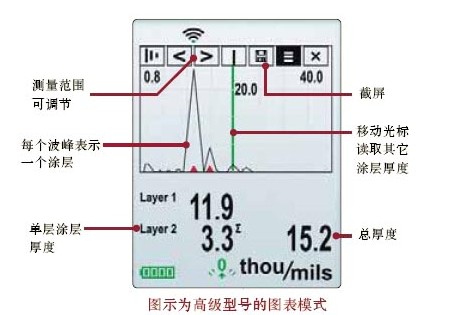

Ultrasonic Coating Precision Ultrasonic Coating Thickness Gauges output graphical data that facilitates detailed coating analysis

Live shot

Select the instrument model with the appropriate measuring range

Standard Advanced

The B-type probe measures wood, plastic, etc The C-probe measures concrete, fiberglass, etc

polymer coating on the material coating on the material

Precision Ultrasonic Coating Thickness Gauge Model Measurement Range

Defelsko B Standard 200B1-E Ultrasonic Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement range | 13~1000μm |

| Probe style | Split probe |

| Lower limit of pipe measurement | 13μm |

| Measurement error | ±(3%H+2)μm |

| Display resolution | 1μm |

| unit system | μm/mils |

| Storage Capacity | 250 pieces |

| statistical function | Average, standard deviation, minimum/maximum thickness and number of readings |

| Standards | ASTM D6132、ISO 2808 |

| Display | LCD screen |

| Operating language | Chinese, English |

| Interface | USB |

| Application Software | Yes. |

| Protection level | Resistant to solvents, acids, oils, water and dust |

| Power Supply | 3 * 7 battery |

| Host size | 127*66*25.4mm |

| Weight | 137G (without battery) |

| Application | Wood, plastic, etc. polymer coatings |

| calibration standard | DeFelsko STDA3 |

Defelsko B Standard 200B1-E Ultrasonic Thickness Gauge Packing list

host x1, probe x1, standard foil x1, coupling agent x1, rubber protective cover with waist clip x1, No. 7 battery x3, nylon portable soft bag x1, English manual x1, certificate x1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveJJF 1224-2009

- ActiveJJF 1126-2004

- ASTM E797-2021

- AbolishGB/T 11344-2008

- ActiveASTM D 6132-2020

- AbolishISO 2808-2007

- JJF 1126-2004

- AbolishZB N 77001-1989

Defelsko

Defelsko B Standard 200B1-E

B Standard 200B1-E

B Advanced 200B3-E

B Advanced 200B3-E