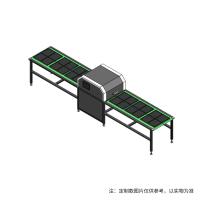

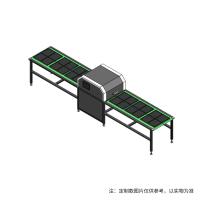

Oven coil automatic composite Coater with unwinding + scraping + drying + covering + winding function

With unwinding, scraping, drying, overlaying, winding functions, with drawdown blade + roller coating double Spreader head device, compound speed 1-10m/min, wet film thickness 0.005-3mm, composite rubber roller heating temperature up to 200 ℃.

Factory

Factory-

Roll-to-Roll Small Spreader Compounding Machine with Roll + Scratch + Drying + Roll Function 2 meters oven

$ 23752.00 -

Non-woven coil Coater Small coil film laminating machine, unwinding → scraping → drying → scraping → drying → film laminating → winding function

$ 22173.00 -

Rxg-01/500sc sheet continuous automatic glue injection machine, spray coating machine

$ 39539.00 -

Factory Direct RTRMA-600 double station unwinding, laminating, hot pressing and winding all-in-one machine 600mm wide multi-layer composite

$ 23752.00 -

Drawdown blade Coater Continuous Experimental Film Applicator 60cm Unwinding + Scratching + Drying + Winding

$ 31646.00

Introduction

The small coating laminating machine is suitable for water-based adhesive coating on non-elastic materials such as paper, film, aluminum foil, plastic, non-woven fabrics, etc. It is an oven-coated automatic composite coating machine with functions of unwinding, scraping, drying, laminating and rewinding.

product structure

The machine consists of a machine body, a gluing width adjustment device, a feeding rack, a gluing roller set, a thickness adjustment dial indicator, a transmission platform, a traction roller set, and a transmission mechanism.

1. Body: The body of the equipment is entirely composed of aluminum alloy + high-static spraying plate.

2. Glue width adjustment device: The width adjustment device is composed of food-grade plastic and adjustable supports.

3. Unloading rack: The machine is equipped with two unloading racks. When the two materials are misaligned during the laminating process, the deviation correction device automatically adjusts to move the rack left and right to achieve the effect of aligning the two materials.

4. Glue coating roller set: The rubber coating roller set is made of double roller precision machined parts with smooth transmission.

6. Thickness adjustment dial indicator: Adjust the required coating thickness when applying glue. Rotate the left and right hand wheels on the rubber coating roller frame clockwise or counterclockwise to adjust the thickness of the glue coating. The specific thickness is determined according to the dial indicator.

7. Transmission platform: The transmission platform is made of stainless steel. Its main function is to smoothly transmit the base material after gluing to the next process.

8. Traction roller group: Pull the base material between the upper and lower rollers of the traction roller by hand. Tighten the handwheel on the frame to make the traction roller and the rubber ring of the upper roller contact the lower roller. The traction roller group will drive the base material through power transmission. The material is pulled over to complete the coating work .

Factory NBC-DJ3-JCHX-500 Automatic oven coaterSpecifications

| LIST | VALUE |

|---|---|

| Coating method | Drawdown blade + roller coating |

| compound velocity | 1-10M/min (slow compounding speed, servo control, adjustable above 0.1m/min) |

| composite width | 100-300Mm adjustable |

| WFT | 0.005-3mm |

| Device size | Approx. Length 1800X Width 800X Height 1600mm |

| maximum discharge | 300mm |

| Maximum charge | 300mm |

| Coating size | Max.300mm |

| Drying Temperature range | Room temperature -200 ℃ |

| Drying tunnel length | 1m |

| Drying Power | 1KW |

| Power | 220V/2.5KW |

| Composite rubber roller | Heating temperature: room temperature~ 200 ℃ |

| Composite Accuracy | 0.5mm |

| Spreader head | Spreader head device, drawdown blade + roller coating switch freely |

Factory NBC-DJ3-JCHX-500 Automatic oven coater Packing list

Machine x1, Manual x1, Encasement List x1, Certificate of Conformity x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Overview of Roll-to-Roll Film Applicator Technology

- Pressure sensitive adhesive coaters: technical features, principles, operation

- Deep analysis of tension control principle of coater coil

- Technical principle and application of plaster coil coater

- In-depth analysis of small coil coater technology and selection points

- In-depth understanding of laboratory coaters: technical principles and industry applications

- Detailed explanation of heating coil coater technology and introduction of heating system

- Application of coater in preparation of polyvinyl alcohol interlayer film

- Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

- Review of laboratory film coater technology and selection method

NBC-DJ3-JCHX-500

NBC-DJ3-JCHX-500

NBC-DJ6-500

NBC-DJ6-500