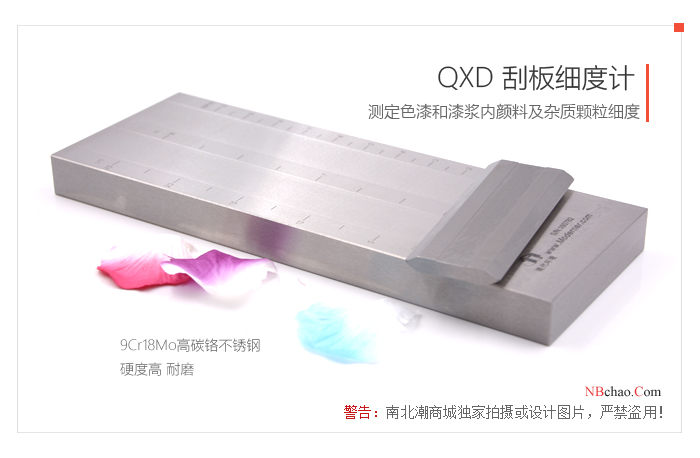

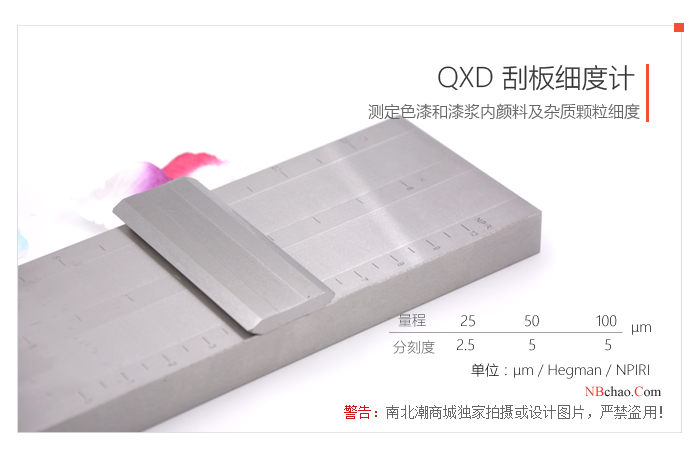

MODERNER QXD 25 Large double-channel Fineness gauge Fineness range 0~25μm

Large double-channel, range 0~25μm, Graduation 2.5μm, stainless steel, scale unit μm.

Moderner

Moderner-

TQC VF2118 double-channel fineness grindometer 0-250 µm with calibrated certificate

$ 1354.00 -

TRUIT TR 1201/100 single-channe Fineness gauge 0~100μm

$ 168.00 -

British Sheen Ref. 504/50 wide/single-channe Grindometer

$ 624.00 -

Pushen ISO-25um double-channel Fineness gauge 0-25μm

$ 195.00 -

TRUIT TR 1201/050 single-channe Fineness meter 0~50μm

$ 168.00

Overview

In the MODERNER, there are a variety of specifications in the R&D and design of scraper Fineness Meters, including general single and double grooves, wide grooves, and large wide grooves. This large double-groove Grindometer is a Grindometer with a large chute width. The range of this QXD 25 large double-groove Grindometer is 0~25μm, the graduation value is 2.5μm, and the chute is chuteThe width is 5.4mm. It is suitable for some users with special needs.

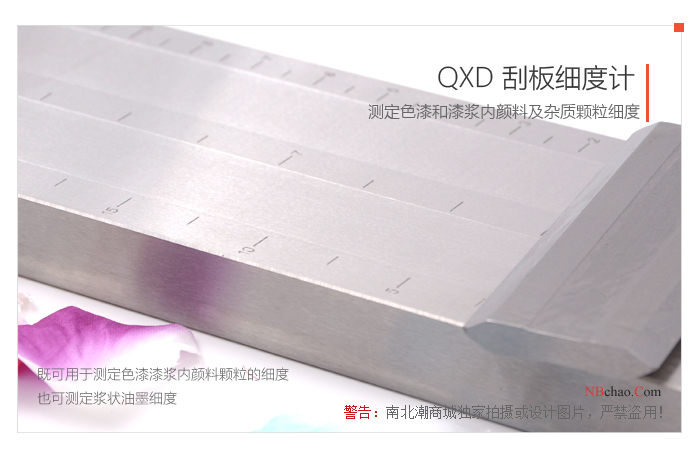

Large double-groove fineness scraperQXD 25In line with the national standard, it is mainly used to determine the fineness of pigments and impurities and other particles in pigments and paint paste. The large double groove fineness scraper is made of stainless steel, equipped with a 95mm scraper, and the width of the chute is larger than that of the general fineness plate. The fineness scraper is designed and manufactured according to the Ministry of Chemical Industry of the People's Republic of CHINA Coating Special Appliance Verification Regulations JJG (Chemical) 018-96 "Scraper Fineness Meter" and its GB/T1724 standard.

Features

1) QXD25 large double-groove Grindometer is widely used in the determination of grinding fineness of pigments, varnishes, printing inks and other materials

2) Fineness is expressed in micrometers (μm) or Hegman scale

3) Comply with standards: GB/T 1724, GB/T 13217.3, ISO 1524, ASTM D1210

4)QXD 25 Large Double Groove GrindometerMade of stainless steel

Live shot

Directions:

(1) Before use, the QXD25 Grindometer should be washed and soaked with a suitable solvent, including the scraper and the bottom, and dried with cotton yarn, and the sample that meets the standard viscosity index of the product should be fully stirred with a paint mixing knife.

(2) InQXD 25 Large Double Groove GrindometerIn the deepest part of the trench, drop a few drops of the sample, and it is advisable to fill the trench and slightly excess.

(3) Hold the spatula with the thumb, index finger and middle finger of both hands. It is placed horizontally at the upper end of the double-groove Grindometer, so that the scraper is perpendicular to the surface of the Grindometer, and the scraper is pulled from the deep part of the groove to the shallow part at an appropriate speed, so that the paint sample is filled with the groove and there is no excess paint left on the flat plate.

(4) After scraping, immediately (not more than 5 seconds) pinch the Fineness Meter and tilt it, so that the line of sight and the plane of the trench are 15-30° to observe the scale value of the evenly exposed particles in the trench, and the reading value is the fineness value of the measured object.

Precautions

(1) Do not scratch the surface of the Grindometer and the scraper

(2) The QXD 25 large double-groove Grindometer should be cleaned immediately after use and coated with petroleum jelly to prevent rust

(3) When measuring the fineness, the clear oil that meets the product standard should be adjusted and then measured

(4) Regularly (one year) check the straightness of the knife edge and Fineness Meter, and find that the unevenness or scraper Fineness Meter is worn, it needs to be corrected by the national metrology verification agency before it can be used.

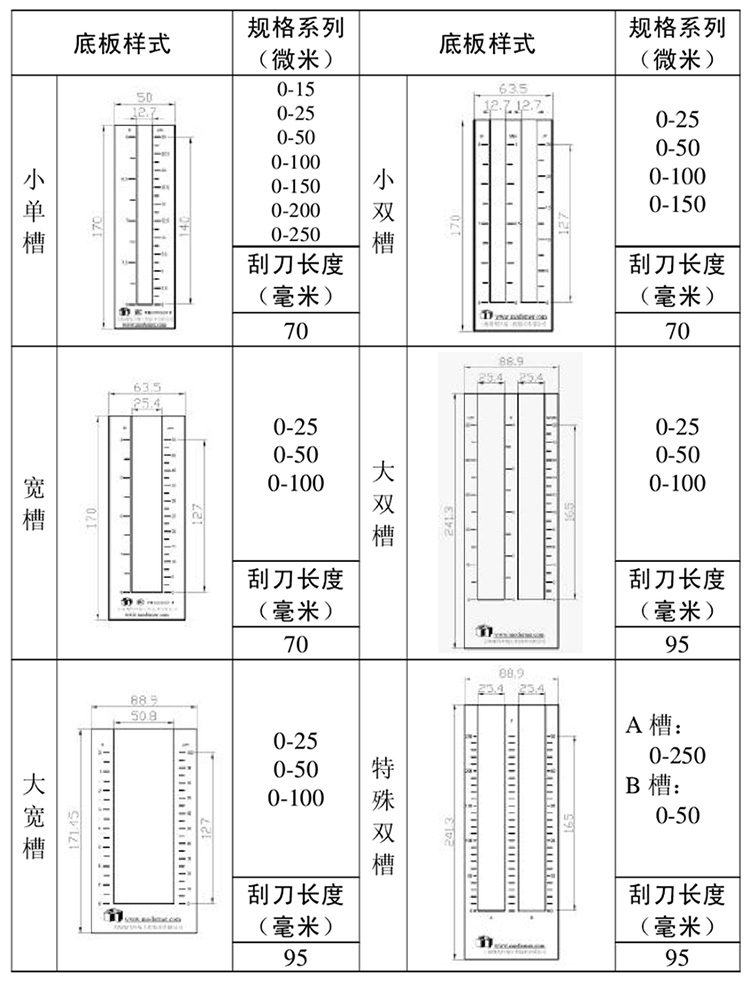

A list of specifications for the MODERNERal scraper Fineness Meter series

Series selection

| specification | Range | Graduation value | Groove size | unit |

| Small single slot | 0-15 | 0.75 | 12.7*140 | μm |

| 0-25 | 1.25 | Hegman/μm | ||

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| 0-150 | 5 | μm | ||

| Small double slots | 0-25 | 2.5 | Hegman/μm | |

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| 0-150 | 5 | μm | ||

| Wide grooves | 0-25 | 1.25 | 25.4*127 | Hegman/μm |

| 0-50 | 2.5 | |||

| 0-100 | 5 | |||

| Large wide slots | 0-25 | 2.5 | 50.8*127 | |

| 0-50 | 5 | |||

| 0-100 | 5 | |||

| Large double slots | 0-25 | 2.5 | 25.4*165 | Hegman/μm/NPIRI |

| 0-50 | 5 | |||

| 0-100 | 5 | |||

| Special double slots | 0-50 | 2 | μm | |

| 0-250 | 10 | μm |

Moderner QXD 25 (large double-channel) Large double-channel Fineness gaugeSpecifications

| LIST | VALUE |

|---|---|

| Scraper type | Big double-channel |

| Number of grooves | 2 |

| range | 0~25μm |

| Scale unit | μm |

| scraper material | stainless steel |

| Scraper size | 241.3*88.9*19.05mm |

| Groove size | 25.4*165mm |

| Drawdown blade material | stainless steel |

| Drawdown blade size | 95mm |

| Applicable standards | GB/T 1724、GB/T 13217.3、ISO 1524、ASTM D1210 |

| Graduation | 2.5μm |

Moderner QXD 25 (large double-channel) Large double-channel Fineness gauge Packing list

Scraper x1, scraper x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- IncomingGB/T 17001.3-2025

- ActiveHG/T 5173-2017

- ActiveGB/T 17473.2-2008

- ActiveGB/T 42541-2023

- ActiveGB/T 17001.6-2022

- ActiveHG/T 5776-2020

- ActiveHG/T 5370-2018

- ActiveHG/T 5175-2017

- ActiveQB/T 2025-2013

- ActiveASTM D3794-2022

- ActiveJT/T 821.2-2011

- ActiveJT/T 821.1-2011

- ActiveASTM D1210-05-2022

- ActiveJB/T 9385-2017

- ActiveGB/T 1724-2019

- ActiveASTM D1316-2020

- ActiveJJG 905-2010

- ActiveASTM D333-2021

- ActiveISO 1524-2020

- AbolishGB/T 13217.3-2008

QXD 25 (large double-channel)

QXD 25 (large double-channel)