LEEB LT100-3 + F1 Coating Thickness Gauge with F1 Probe, Range 0-1500μm

F1 Probe, Magnetic Induction Thickness Measurement range 0-1500μm, accuracy +/- 3%, support one point/two point/basic three Calibration methods, can store 500 data.

Leeb

Leeb-

YIBAI CTG-600F10 Single iron Coating Thickness Gauge 10mm

$ 350.00 -

AMITTARI AC-110MC Integrated Coating Thickness Gauge Dual function Film Thickness Gauge 0~500μm

$ 269.00 -

DUBAN DB20-CM212 Statistical Coating Thickness Gauge integrated probe 0~1250µm

$ 580.00 -

Defelsko PosiTector 6000 N90S1 Coating Thickness Gauge 90 ° Miniature probe, standard

$ 1309.00 -

AMITTARI AC-112-200NF Coating Thickness Gauge Aluminum-based Film Thickness Gauge

$ 620.00

Overview

The LT100-3 series cladding Thickness Gauge adopts two methods of magnetic and eddy current thickness measurement, which can non-destructively measure the thickness of the non-magnetic covering layer (such as aluminum, chromium, copper, enamel, rubber, paint, etc.) on the magnetic metal matrix (such as steel, iron, alloy and hard magnetic steel, etc.) and the thickness of the non-conductive covering layer (such as enamel, rubber, paint, plastic, etc.) on the non-magnetic metal matrix (such as copper, aluminum, zinc, tin, etc.).

This instrument can be widely used in electroplating, anti-corrosion, aerospace, chemical industry, automobile, shipbuilding, light industry, commodity inspection and other testing fields.

Features

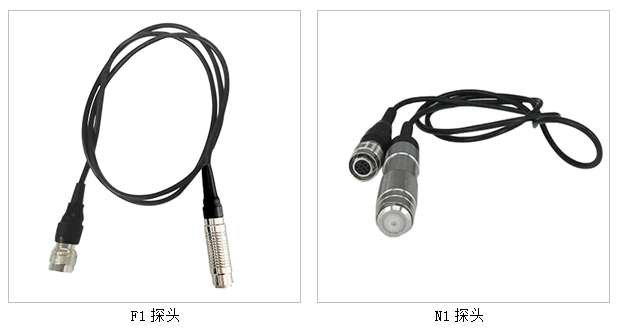

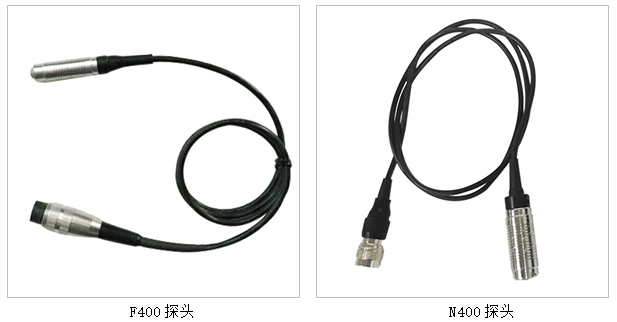

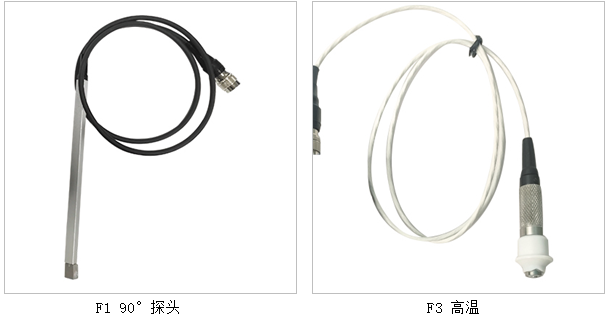

A wide range of probes can be used (F400, F05, F1, F3, F3 High Temperature, F1, F1/90°, F10, N1, N400, N3, N05).and other probes, etc.);

Three calibration methods: one-point calibration, two-point calibration, and basic calibration;

Display resolution: 0.1um below 1250um, 1um above 1250um);

There are four statistical functions: maximum value (MAX), minimum value (MIN), average value (MEA), number of measurements (No)

Set up five statistics and store 500 pieces of data.

Probes are optional

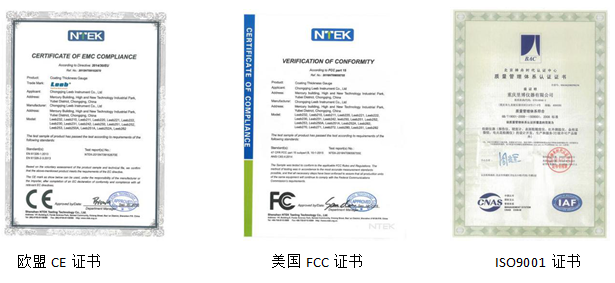

Certificate display

Leeb LT100-3+F1 Cladding Thickness GaugeSpecifications

| LIST | VALUE |

|---|---|

| Thickness Measurement Range | 0~1500μm |

| Measurement error | +/- (3% H + 1) um, H is the actual thickness of the measured object |

| Environmental temperature | 0~40 ℃, F3 high temperature: 0-300 ℃ |

| Power Supply | AA type alkaline battery 1.5V two |

| Dimensions | 150*80*30mm |

| Weight | 300g |

| statistical function | MAX Maximum (MAX), MIN Minimum (MIN), Average (MEA), Number of measurements (No) |

| Data storage | 500 pieces of data |

| Calibrated mode | One point calibrated, two point calibrated, basic calibrated |

| Measurement principle | Magnetic Induction |

| Thickness probe | F1 |

Leeb LT100-3+F1 Cladding Thickness Gauge Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle, Characteristics and Application of FISCHER Coating Thickness Gauge

- Basic Principle, Characteristics and Application of Rubber Coating Thickness Gauge

- Application, Principle Introduction and Precautions for Selection of Pipeline Thickness Gauges

- Basic principle and application scenario of steel Coating Thickness Gauge

LT100-3+F1

LT100-3+F1