China Perovskite Experimental Film Applicator TBJ-X4-ABO3 bar + Drawdown blade + Heating + Air knife

The TBJ-X4-ABO3 China Perovskite Film Applicator is a professional equipment equipped with high-precision Mayer Rods, with heating, air knife and air knife holder functions. Using nitrogen as the gas source, the air knife can be adjusted 360 degrees, making the dry-film after Spreader very thin, up to nano level.

zy

zy-

CHINA metering rod & drawdown blade vacuum adsorption small Coater TBJ-X2-DJ12 Coating size 400 * 500mm

$ 5597.00 -

Domestic (CN) TBJ-A1-XB500g Automatic Film Applicator bar type Automatic Film Applicator

$ 1935.00 -

HuiNuo TM3000Pro/15 bar drawdown blade Coater ECA 100 * 60cm servo motor

Login -

HUINUO TM1200/01 Wire Rod Vacuum adsorption Coater Rod Film Applicator Customized

$ 4492.00 -

HuiNuo TM3300Pro/29 drawdown Bar & Blade Heating Vacuum chuck Coater Automatic Film Applicator 100 * 50cm

Login

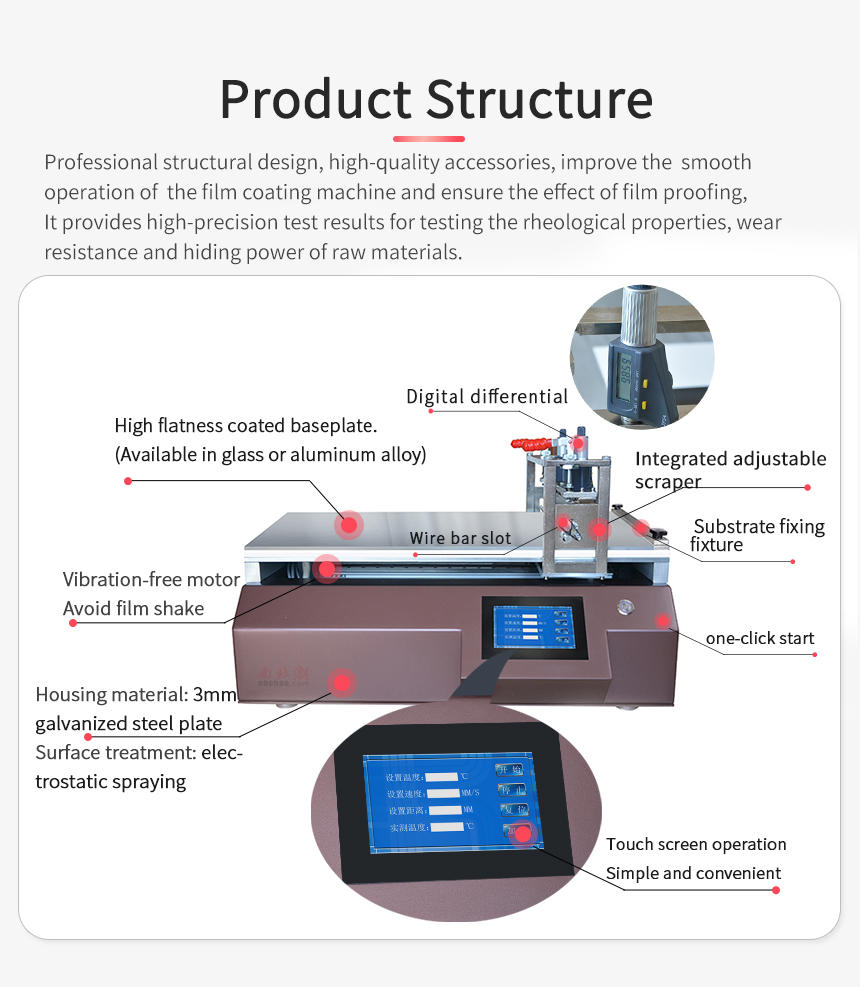

product description

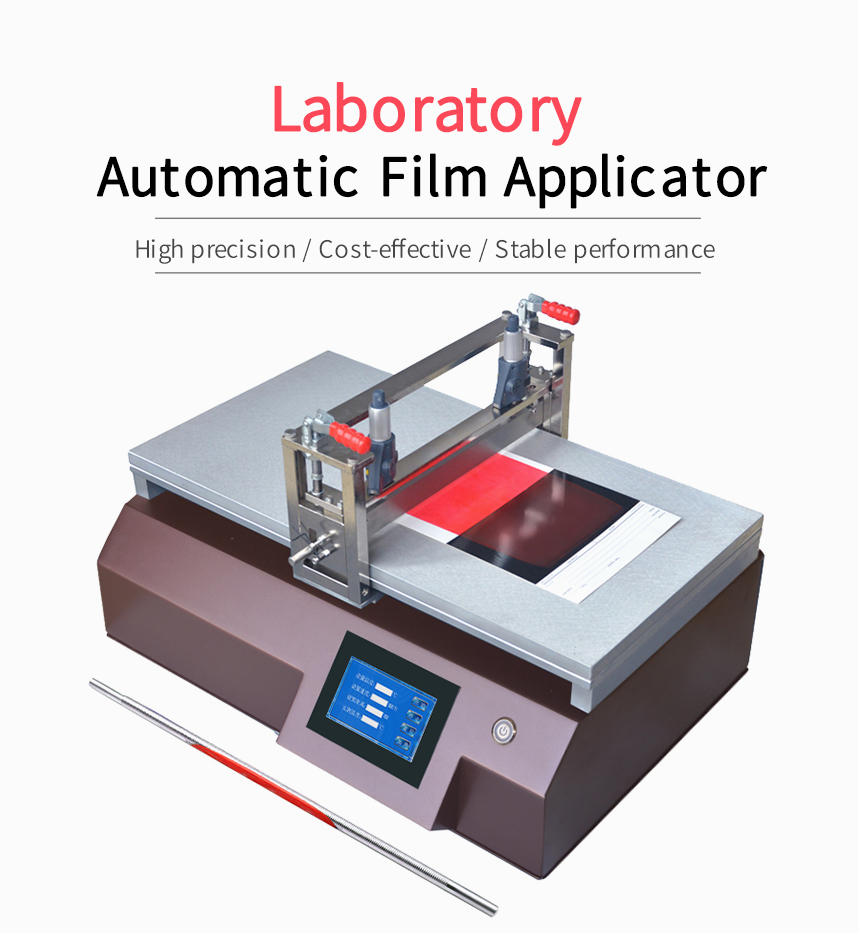

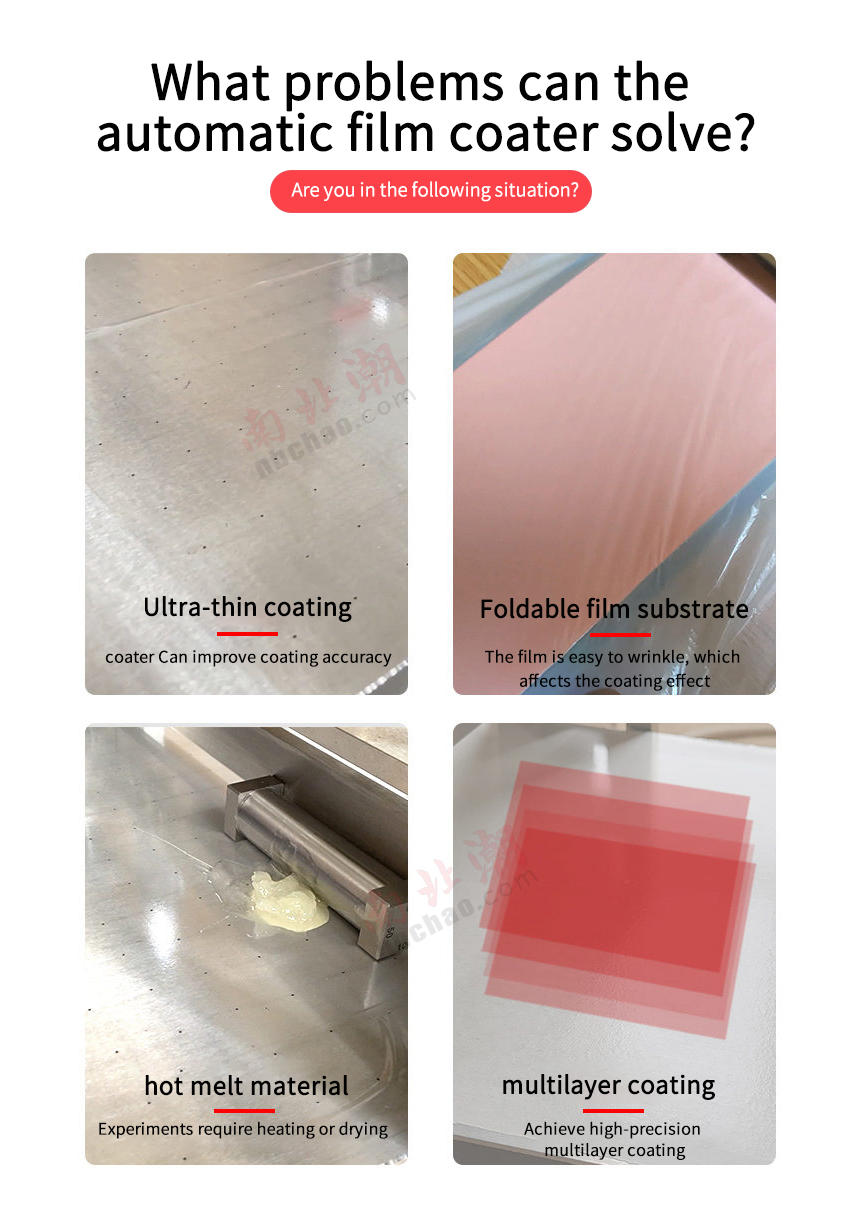

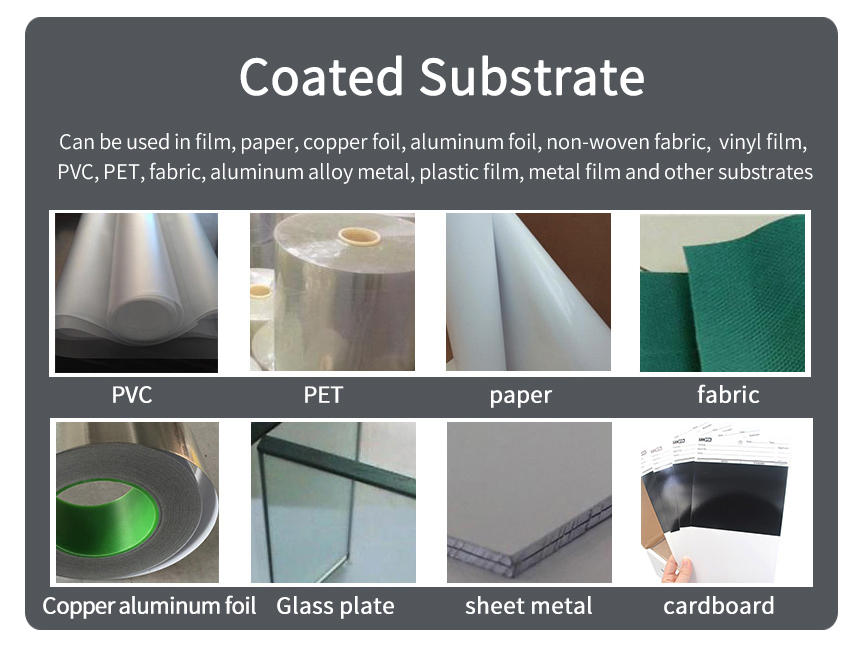

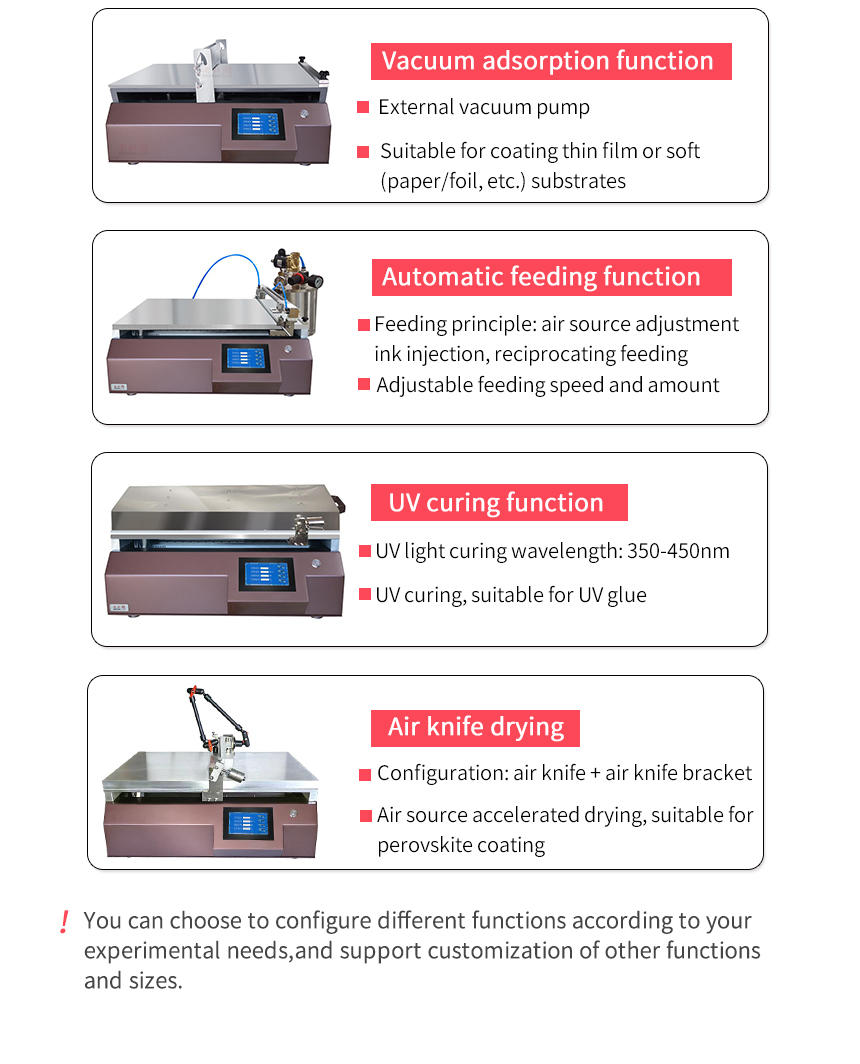

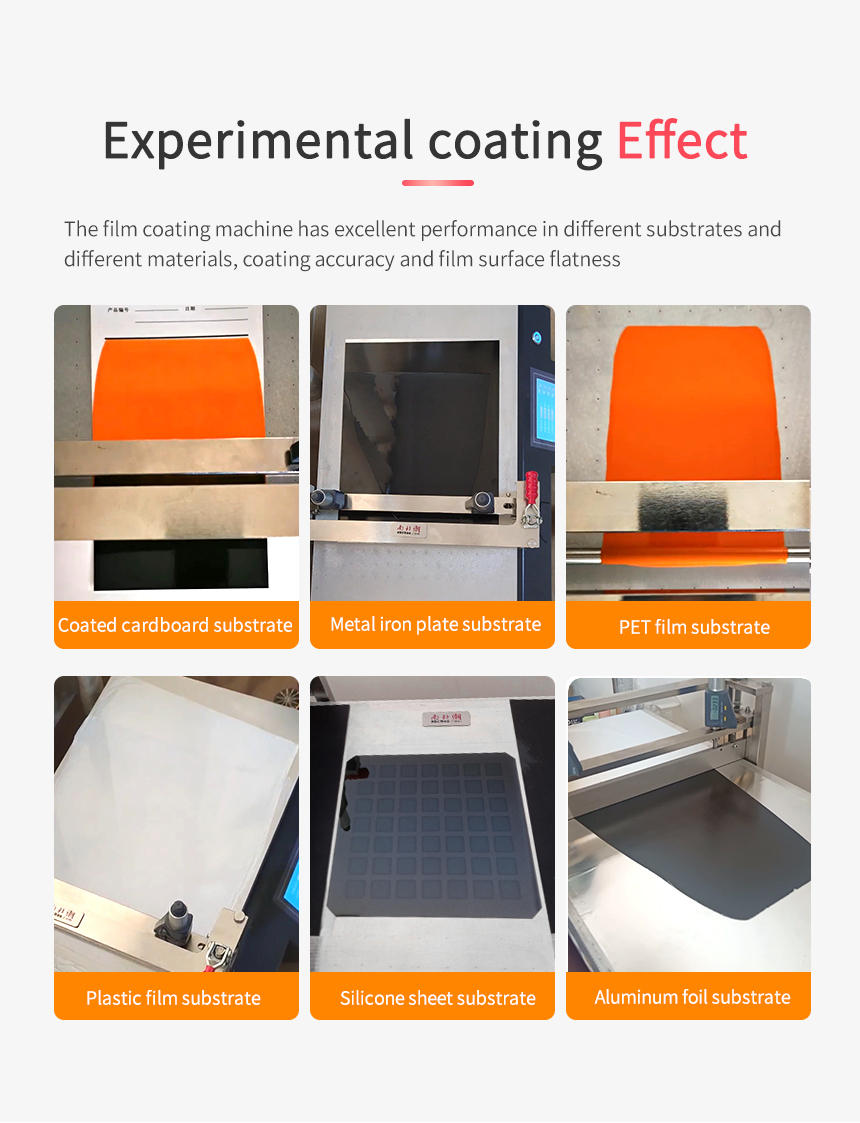

The perovskite special film coating machine is equipped with imported high-precision wire rod coater, which has heating and vacuum adsorption functions, and is equipped with air knife and air knife bracket. Nitrogen is used as the air source to accelerate drying of the perovskite solution, and the air knife can be 360 degrees. Angle adjustment, the thinnest dry film can reach nanometer level.

The emergence of the film coating machine is due to the main factors affecting the film coating are the coating speed and the pressure applied on the Film Applicator, etc., so the coatings painted by hand are often inconsistent, especially the differences between different people. Larger, which brings difficulties to compare the test results between the models. The automatic film coating machine is carefully designed to allow the operator to conveniently apply precise wet films on different substrates, which greatly improves the reproducibility of the coating film.

Optional

zy TBJ-X4-ABO3 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Drawdown blade Accuracy | ±0.003mm |

| Drawdown blade Film thickness range | 0~10Mm drawdown blade can be lifted |

| Coating speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Coating size | 300*400mm |

| Coating method | Bar + drawdown blade + air knife |

| Rod Film thickness range | 1~ 571.5 μm (Spreader Film thickness according to bar type) |

| Mayer Rod Accuracy | ±0.001mm |

| Host Power Supply | 220V 50Hz |

| Weight | Net Weight 65KG |

| speed control | Infinitely variable speed |

| Coating table material | aluminum alloy |

| Spreader Accuracy | 0.001mm |

| configuration function | Air knife + air knife bracket |

| Dimensions | 630*410*520mm |

| Heating temperature range | RT+~180℃ |

| Temperature Uniformity | ±3℃ |

| Air knife gap | 0.05mm |

| Air knife Accuracy | ±0.002mm |

zy TBJ-X4-ABO3 Automatic Film Applicator Packing list

Film Applicator X1, Drawdown blade X1, imported bar X1, air knife x1, air knife bracket x1, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Five different coating methods and characteristics

- Double-sided tape coater: Selection and Troubleshooting Guide

- Analysis and application of self-adhesive laboratory coater technology

- The Film Applicator You Think Is Not What You Think

- Advantages of drawdown blade method in preparation of perovskite solar cells

- Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

- Comparison and Difference Between Offset Press and Film Applicator

- Selection and operation process of polymer structure glue coater

- Comparison of Different Spreader Methods of Small Coating coater

- Bar & casting knife heating Film Applicator Application of Water Treatment Film on Non-woven Fabric

TBJ-X4-ABO3

TBJ-X4-ABO3

TBJ-X4-ABO4

TBJ-X4-ABO4

TBJ-B4-ABO

TBJ-B4-ABO