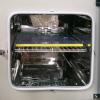

CHINA DGG-9240A Desktop Forced Air Drying Oven heater Drying Oven 200 ℃/225L

Working temperature 5~ 30 ℃, Relative Humidity ≤ 80%, altitude ≤ 2000m, power supply AC220V +/- 10% 50Hz +/- 1Hz, control range room temperature + 10 ℃~ 200 ℃, Temperature resolution 0.1 ℃, Temperature Fluctuation +/- 0.5 ℃, size internal 600 * 500 * 750.

Factory

Factory-

HUITAI HHG-9149A High temperature blast drying oven Volume 140L

$ 1602.00 -

Kenton KH-25A digital display electric drying oven with independent temperature limiter

$ 279.00 -

HUITAI GRX-9123A Dry Baking Autoclave Volume 136L

Login -

Kenton DZF-6090 Constant temperature vacuum Drying Oven, cold rolled plate liner

$ 981.00 -

YIHENG DHG-9425A Forced Air Drying Oven Volume 420L Temperature control: 10~300 ℃

$ 1998.00

Features

1. Horizontal constant-temperature Forced Air Drying Oven for small experiments is horizontal, back-heated, and horizontal forced convection to ensure uniform temperature in the studio.

2. The temperature control system uses high-performance CPU processing chips and high-sensitivity, high-precision platinum resistance sensors to make temperature control more efficient and operation more convenient.

3. The horizontal constant temperature Forced Air Drying Oven for small experiments has sensor failure alarm, over-temperature alarm, self-diagnosis dynamic control, temperature display correction, parameter memory and timing functions up to 9999 minutes.

4. The optional independent temperature limit control system automatically interrupts work when the temperature exceeds a certain temperature. (optional)

Series model

| model | 9030A | 9070A | 9140A | 9240A | |

| Operating Environment | Ambient temperature 5~30℃ | ||||

| Relative Humidity â¤80% | |||||

| Altitude ⤠2000m | |||||

| Power supply AC220V±10% 50Hz±1Hz | |||||

| Control range | Room temperature +10℃~200℃ | ||||

| temperature | resolution | 0.1℃ | |||

| Volatility | ±0.5℃ | ||||

| controller | LCD display, push button, microprocessor temperature control with fuzzy PID control technology | ||||

| sensor | High precision platinum resistance sensor | ||||

| time | 0~9999 minutes | ||||

| Power consumption | 650W | 850W | 1450W | 2000W | |

| Material | internal | 304 mirror stainless steel | |||

| external | 08F cold rolled steel plate | ||||

| size | internal | 340*320*320 | 450*400*450 | 550*450*550 | 600*500*750 |

| (MM) | external | 620*530*490 | 740*618*630 | 840*670*730 | 880*720*930 |

Precautions for use:

1. Please check the electrical performance of this box before powering on, and pay attention to whether there is an open circuit or leakage.

2. When everything is ready, you can put the test sample in, close the door and unscrew the exhaust valve on the top. At this time, you can connect the power supply and start working.

3. Do not remove the side door at will, disturb or change the circuit. Only when the box fails, you can remove the side door and check the circuit one by one.

4. This box is a non-explosion-proof drying box, so it contains flammable and volatile items. Do not put them in the drying box to avoid accidents.

Factory DGG-9240A Desktop Forced Air Drying OvenSpecifications

| LIST | VALUE |

|---|---|

| Ambient Temperature | 5~30℃ |

| Relative Humidity | ≤80% |

| Altitude | ≤2000m |

| Power | AC220V±10% 50Hz±1Hz |

| Temperature range | RT+10~200℃ |

| Temperature Resolution | 0.1℃ |

| Temperature Fluctuation | ±0.5℃ |

| Thermostat | Liquid crystal display, push-button, fuzzy PID control technology for microprocessor temperature control |

| Temperature transducer | High-Precision Platinum Resistance Sensors |

| Timer | 0~9999min |

| Power Consumption | 2000W |

| Chamber material | 304 mirror stainless steel |

| Enclosure Material | 08F Cold rolled steel plate |

| Interior size | 600*500*750mm |

| Dimensions | 880*720*930mm |

Factory DGG-9240A Desktop Forced Air Drying Oven Packing list

machine X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Vacuum oven verification calibrating procedure

- Role and Prospect of Drying Agent in Coating Industry

- Principle, characteristics and application of blast Drying Oven

- Principle, application and selection of Drying Oven with timed blast

- Principle, application and selection of ozone sterilizing oven

- Principle, application and selection of pigment Drying Oven

- Principle, application and selection of small Drying Oven

DGG-9240A

DGG-9240A