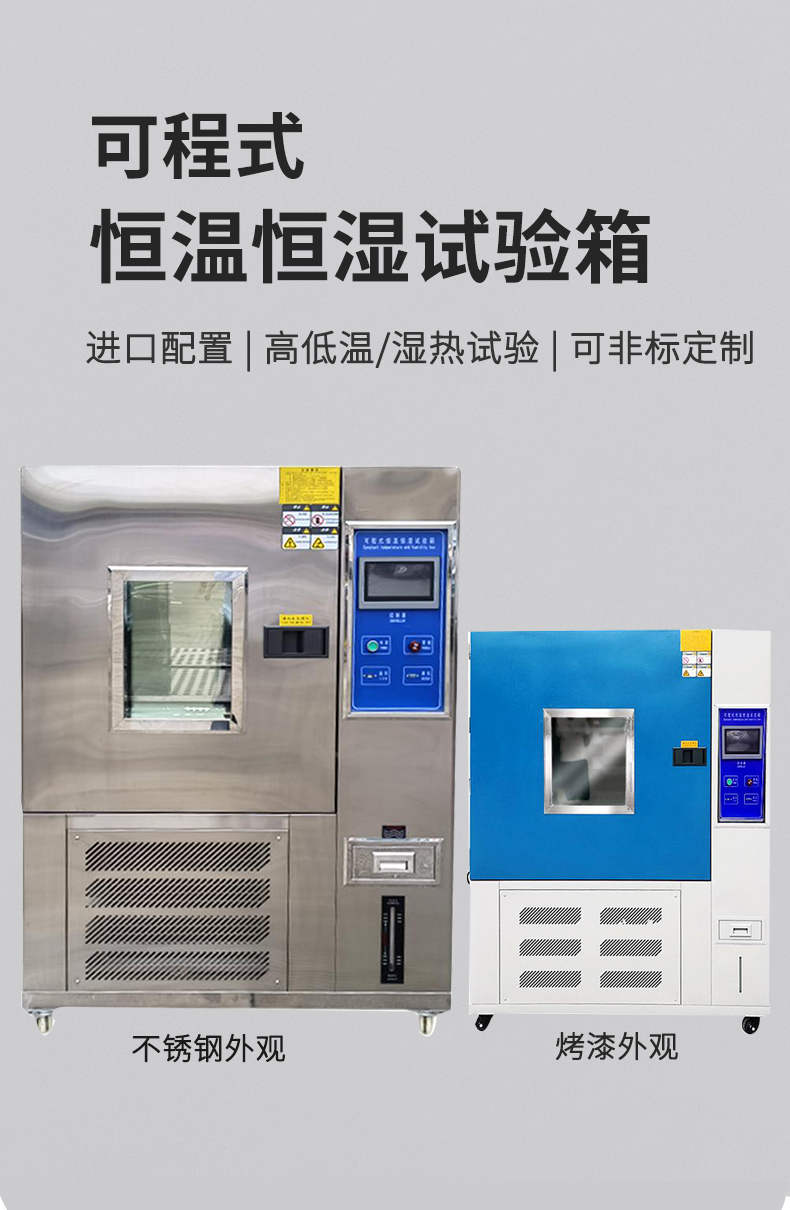

CHINA NBC-225L-20 programmable Humidity Chamber paint panel -20 ℃~ 150 ℃/225L

Temperature range -20 ℃~ 150 ℃, volume 225L, programmable control, using imported compressor, P.I.D automatic calculation control, stable performance, multi-directional protection system.

Factory

Factory-

CHINA NBC-100L-40 Programmable high-low temperature heating and Humidity Chamber, paint Appearance -40 ℃/100L

$ 2571.00 -

CHINA NBC-408L-60 Drug constant temperature and humidity test Room temperature heating and Humidity Chamber -60 ℃/408L

$ 5597.00 -

Lugong ST-408LB Humidity Chamber temperature and humidity environment Test Chamber -40 ℃~ + 150 ℃

$ 4350.00 -

ZKHS GDS-800B high-low temperature Humidity Test Chamber -20~150 ℃/800L

$ 8991.00 -

HUITAI LHS-250SC Constant Temperature and Humidity Chamber 0~ 60 ℃/250L

$ 1712.00

Introduction

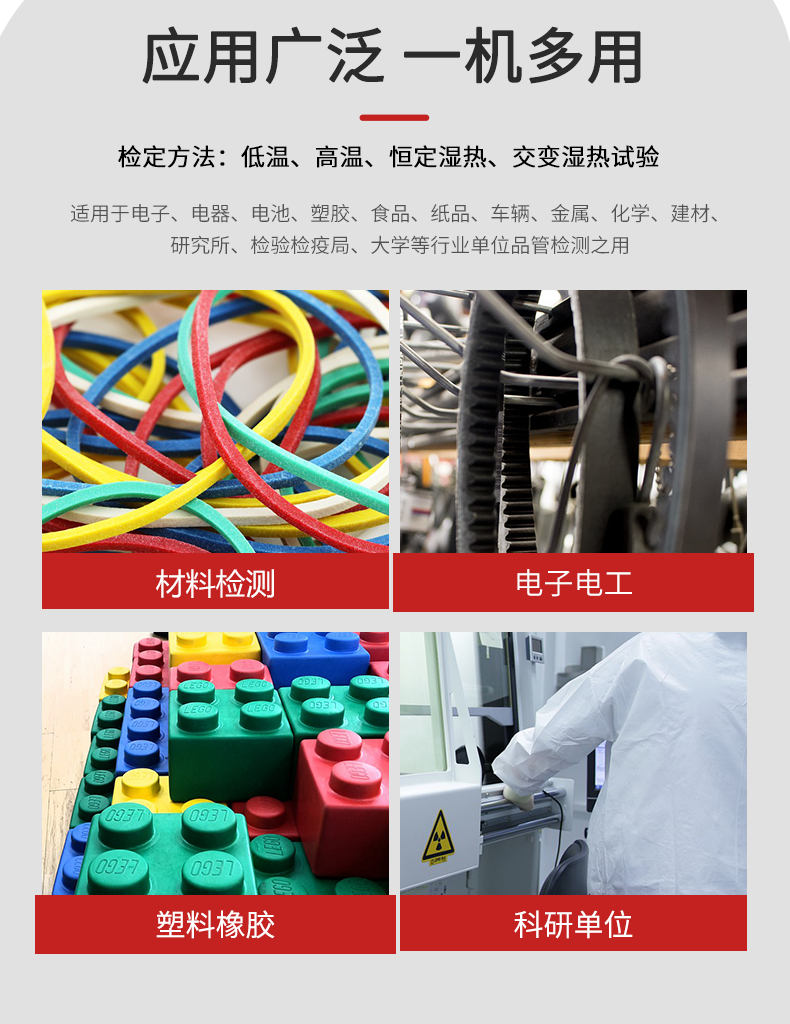

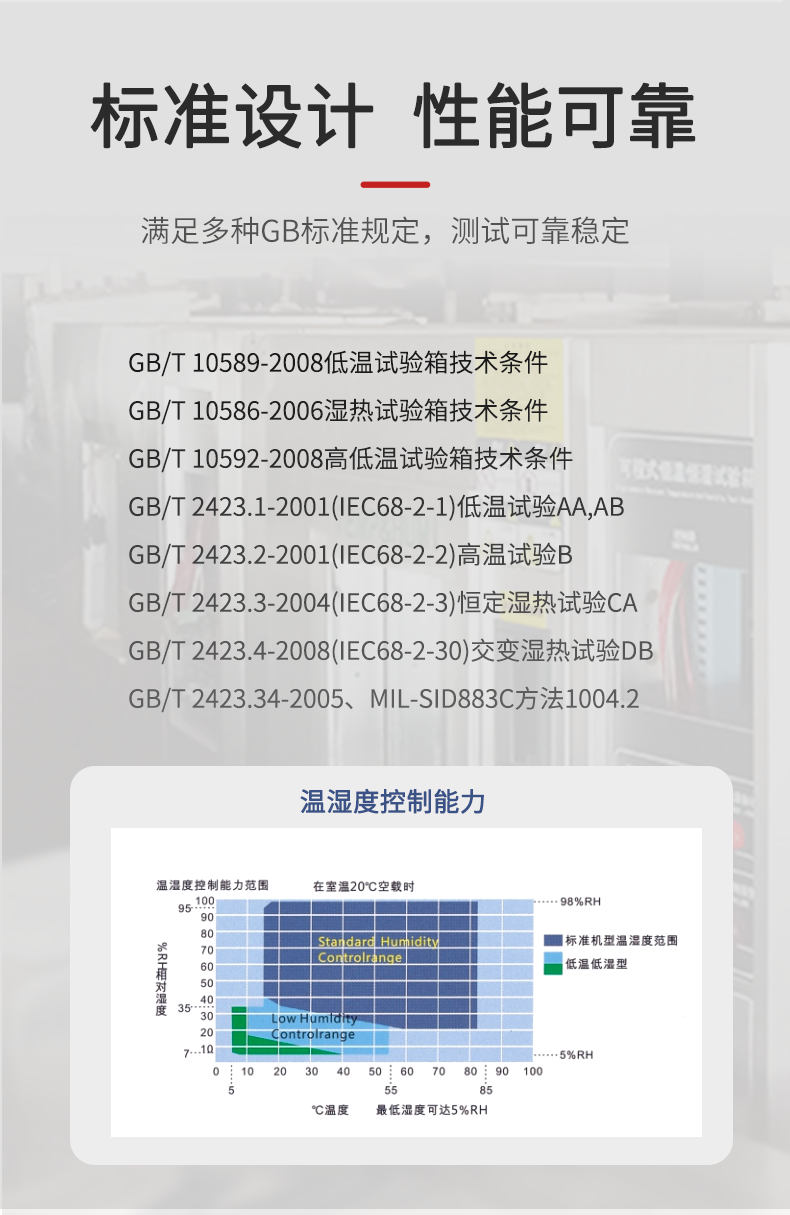

The high-low temperature and humidity alternating Test Chamber is mainly used to test the performance of materials in various environments and to test the heat resistance, cold resistance, dryness resistance and moisture resistance of various materials. Suitable for quality testing of electronics, electrical appliances, communications, instruments, vehicles, plastic products, metals, food, chemicals, building materials, medical, aerospace and other products.

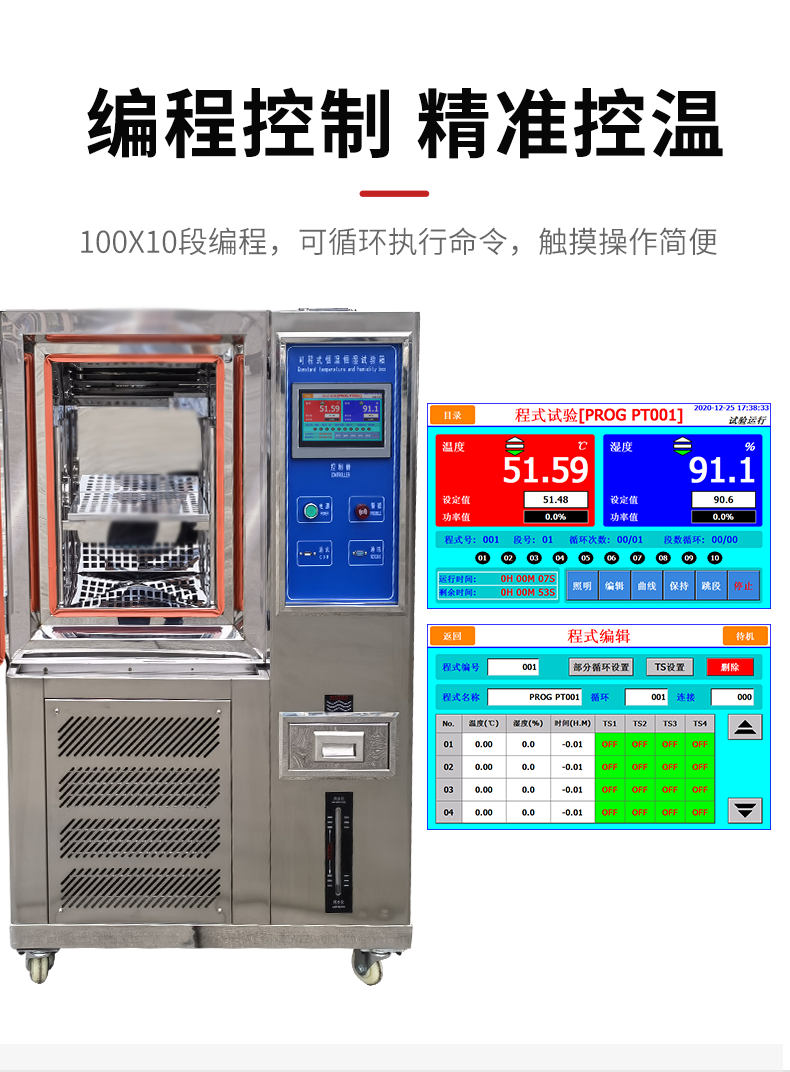

Control method: Using the Balanced Temperature and Humidity Control System (BTHC), the induction system transmits the actual data in the Test Chamber to the controller. The controller controls the SSR, multi-stage intelligent output, and balances the output power of the temperature and humidity system to ensure that the temperature and humidity in the Test Chamber are The temperature and humidity are fully stable, and it has an energy-saving function, which reduces the power usage of the instrument to a greater extent and ensures long-term accurate and stable operation of the instrument.

Features

1. The product has beautiful appearance, reasonable structure, precise technology, simple and convenient operation and stable and reliable performance.

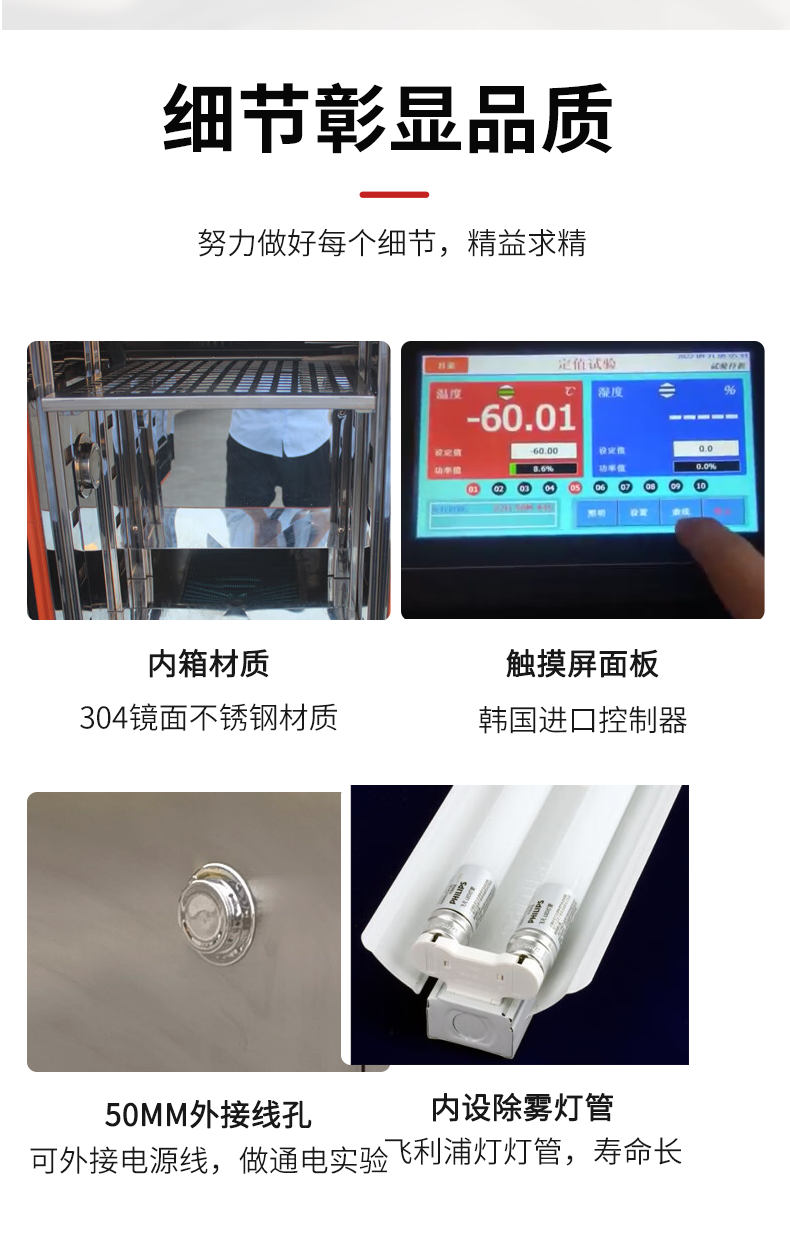

2. The controller adopts a large color LCD human-machine touch dialogue LCD human-machine interface controller, which is simple to operate, easy to learn, stable and reliable, and displays complete system operating status, execution and setting program curves in Chinese and English, and can realize RS232 Computer interface docking, remote control of the instrument directly through the computer.

3. The refrigeration cycle system uses a compressor: an original imported Japanese "Sanyo" brand fully enclosed compressor (optional French Taikang compressor). All components are imported from Japan, France, the United States, Italy and other producing areas. Refrigeration The agent uses American environmentally friendly refrigerant (R23A, R404A).

4. There is a reserved test hole with a diameter of 50mm on the left side of the test box.

5. It has a fully automatic, high-precision system loop, any machine movement, PLC locking processing, all using PID automatic calculation control, and the temperature in the entire area has high precision and high stability.

6. Specially designed air circulation system and sensing system, the air outlet and return air sensor are detected and controlled to ensure the temperature uniformity in the Test Chamber and avoid any dead spots.

7. Adopt an enlarged observation window and 4 layers of tempered glass to provide a wider field of vision.

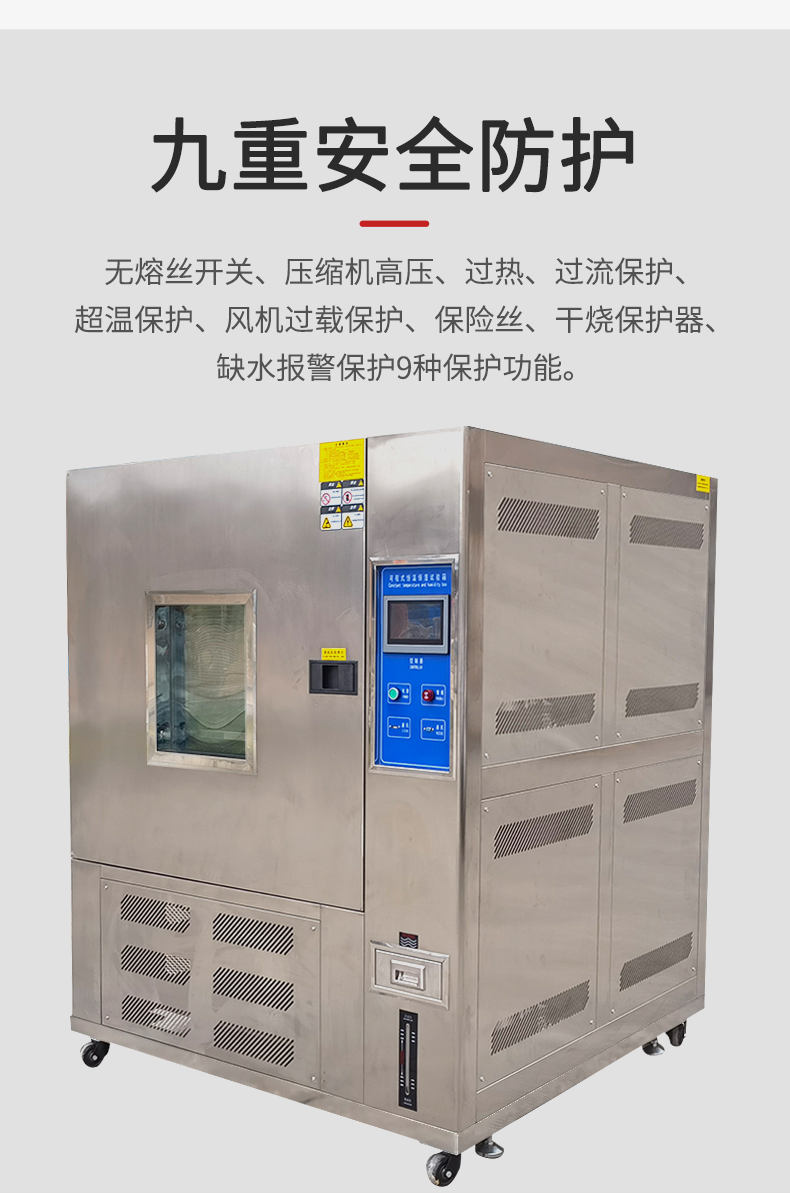

8. The instrument has a comprehensive protection system, including power overload protection, leakage protection, control loop overload, short circuit protection, compressor protection, grounding protection, over-temperature protection, alarm audible prompts, etc. When any abnormal situation occurs, the fault will be automatically displayed on the screen immediately. Point out the reason and automatically shut down.

Factory NBC-225L-20 (paint plate) Programmable Constant Temperature & Humidity Test ChamberSpecifications

| LIST | VALUE |

|---|---|

| Interior Volume | 225L |

| Temperature range | -20~150℃ |

| Temperature Fluctuation | ±0.5-1℃ |

| Temperature Uniformity | ±1.5-2℃ |

| Humidity control range | 20~98%R.H |

| Humidity Deviation | ±1~2% |

| Humidity Uniformity | ±1-3.0%R.H |

| Heating rate | 3 ℃/min nonlinear no-load |

| Cooling rate | 1 ℃/min (no-load nonlinear) |

| Interior size | 600*500*750mm |

| Dimensions | 1120*1050*1620mm |

| Total Weight | ≈218KG |

| Power | 220V/50HZ |

| Permissible Voltage Variation | ±10% |

| Maximum Power | 6kw |

| Inner box material | Mirror stainless steel plate (SUS #304) |

| Enclosure Material | Painted panel |

| Ambient Temperature | 0~30℃ |

| Specification Environment | 5~25℃ |

| Environmental requirements | Miscellaneous items cannot be placed within 60CM |

Factory NBC-225L-20 (paint plate) Programmable Constant Temperature & Humidity Test Chamber Packing list

machine X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of Humidity Chamber in humidity resistance test of photovoltaic backplane adhesive

- Common faults and solutions of Humidity Chamber

- Application of Humidity Chamber in building materials and flooring industry

- Correct operation steps of constant temperature and humidity Test Chamber [video explanation]

- Application of Constant Temperature and Humidity Test Chamber

- How is the Humidity Chamber used in the material humidity resistance test?

- Foam humidity resistance test

- Application of Humidity Chamber in humidity resistance test of hot-melt adhesive

- Application of Humidity Chamber in moisture and heat resistance of grease

- Application of Humidity Chamber in bearing moisture and heat resistance

- ActiveIEC

- ActiveIEC

- ActiveASTM

- IncomingGB/T 42125.4-2024

- ActiveGB/T 2423.34-2024

- ActiveJJF 1564-2016

- ActiveJJF 1270-2010

- ActiveJJF 1101-2019

- 2058-2023

- ActiveHG/T 5173-2017

- ActiveQX/T 16-2020

- ActiveJG/T 25-2017

- ActiveGB/T 31467-2023

- ActiveGB/T 43489-2023

- ActiveGB/T 4893.8-2023

- AbolishGB/T 2423.34-2012

- ActiveGB/T 2423.50-2012

- ActiveGB/T 32065.6-2015

- ActiveQC/T 484-1999

NBC-225L-20 (paint plate)

NBC-225L-20 (paint plate)