China NBC-9015 battery explosion-proof box, battery explosion-proof test chamber

Battery charging and discharging safety test, the size of each layer test box is 500 * 500 * 500mm, the outer box of 3mm thick A3 steel plate is made of SUS #201 stainless steel.

Factory

Factory-

Huida HD-2028 Flexibility Tester, testing of thin leather such as uppers, clothing, bags, etc

$ 1398.00 -

CHINA NBC-5645 Mobile phone soft pressure testing machine, soft pressure life Tester

$ 1055.00 -

SuJie FKC-I planktonic bacteria sampling capacity 100~6000L

$ 1625.00 -

HORIZON ZPY-01 axis deviation Tester, plastic bottle, glass bottle, verticality Tester

$ 1084.00 -

YUZHOU MY-1 Light spectrum belt grinding prototype, stainless steel shell, belt adjustment device

Login

Introduction

A battery explosion-proof box is a device specially designed for the safe storage and testing of batteries, especially for handling and testing batteries that may be at risk of explosion, such as lithium-ion batteries. Battery explosion-proof boxes are designed to provide a safe environment for storing or testing batteries that may present risks such as leakage, overheating, internal short circuits, or chemical instability. The box body is made of strong materials, such as steel or special alloys, which can withstand high pressure and high temperature and prevent flames and explosion shock waves from causing damage to the surrounding environment. During battery testing and transportation, explosion-proof boxes serve as an emergency response tool to reduce the risk of battery failure. Suitable for many types and sizes of batteries, including mobile phone batteries, laptop batteries, electric vehicle battery packs, etc.

use

The battery explosion-proof box is mainly used for personal safety protection in battery safety performance testing. During overcharge and over-discharge, charge and discharge tests and other tests, the battery is placed in the explosion-proof box and connected to an external charge and discharge Tester. Protect operators and instruments.

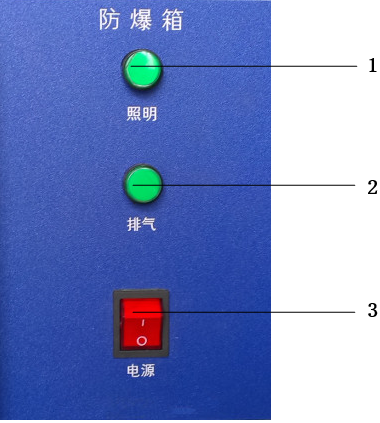

Panel instructions

Instrument installation

Operating environment requirements: room temperature within the range of 10℃-40℃; ambient humidity within 30%-80%

Operating power requirements: The machine power supply is 220V power supply

Others: The machine needs to be installed and positioned on a level and strong platform.

Steps

Confirm the power supply Voltage of the whole machine;

Open the explosion-proof box door and place the test sample in the explosion-proof box.

Turn on the power switch and turn on the lighting and exhaust systems if necessary.

After the test is completed, turn off the lighting system, exhaust system and power supply.

Factory NBC-9015 Battery explosion-proof boxSpecifications

| LIST | VALUE |

|---|---|

| Test box size per floor | 500 * 500 * 500Mm (length * width * height) |

| Enclosure Material | 3MM thick A3 steel plate and treated with paint |

| Inner box material | SUS #201 Stainless Steel |

| Power Supply | AC220V ,A ,50HZ |

| material | steel plate |

| principle | By means of solid box, pressure relief device, temperature and pressure control, etc., the battery can be prevented from exploding. |

| function | Isolation battery, explosion-proof pressure relief, cooling and heat dissipation, monitoring and alarming to ensure safety. |

Factory NBC-9015 Battery explosion-proof box Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

NBC-9015

NBC-9015