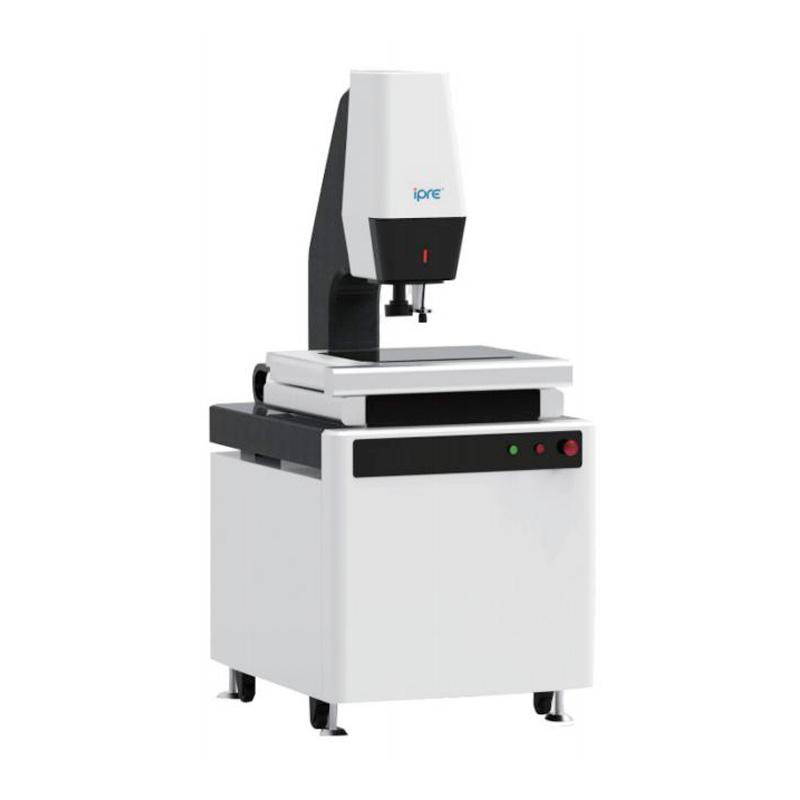

IPRE SC1813 One-button fast imager, measuring range 180mm

Image Sensors uses high definition 20 million pixel CCD, and the Gige Gigabit Ethernet network interface card (transmission rate: 1G/S) makes the imagery clear and the image quality delicate.

Ipre

Ipre-

IPRE SC3020 one-button image Measurement Instrument, measuring range 300mm

$ 16853.00 -

IPRE-Y Benchtop mirror adjustable luminance

$ 9946.00 -

IPRE IPRE YS2 Industrial Endoscope

$ 5705.00 -

IPRE PRRD2 industrial endoscope, depth of field range 10mm-70mm

$ 4618.00 -

IPRE SC1008 One-button fast imager, measuring range 100mm

$ 13203.00

Features

1. Host

Automatic image registration function eliminates the need to position workpieces and fixtures, and products can be placed casually to achieve automatic identification and measurement;

Can identify multiple measurement workpieces at the same time, measure them, and output the results;

The image sensor uses a high-definition 20-megapixel CCD, and the matching Gige Gigabit Ethernet card (transmission rate: 1G/S) makes the image clear and the image quality exquisite;

It adopts a bilateral telecentric lens, equipped with parallel telecentric transmitted light (transmission system), programmable four-zone annular shadowless epilight (epi-illumination system), coaxial epilight and low-angle shadowless epilight (optional light source).

2. Software system

Programming is simple, the software is calibrated through surface compensation, the repeatability of measuring standard parts can reach 0.001mm, and the accuracy of repeated measurement products can be guaranteed to be <0.005mm;

The software has powerful measurement functions. In addition to basic line drawing, distance, angle, radius and diameter measurement, it also adds the highest point, intersection point, contour scanning, electronic caliper, area, contour, longest distance, shortest distance, center functions such as distance.

Software features

| Basic measurement functions | Point, line, circle, multi-point line, multi-point circle, automatic circle, spline, arc, multi-segment circle, automatic R angle, contour scan |

| Annotation function | Alignment dimension, vertical dimension, angle dimension, radius/diameter dimension, area dimension, thread pitch diameter |

| Geometric tolerance | Straightness, roundness, symmetry, contour, etc. |

| virtual construct | Center line, bisector, tangent point, circle line tangent point, circle center, line center, highest point, lowest point |

| parameter settings | Font, color, recognition mode, tolerance size, operation permissions |

| Report function | SPC analysis report (CPK, CA, PPK, CP, PP value, process capability analysis, X control chart, R control chart) |

| Software customization | CAD import contour curve analysis, automated management links, APP management applications |

| Test quantity | 99 data/second |

| Template quantity | No limit |

| Drive mode | Programmable motor |

Ipre SC1813 One button fast Measurement InstrumentSpecifications

| LIST | VALUE |

|---|---|

| measurement | X eighty:180mm;Y eighty:130mm;Z eighty:40mm |

| Image Sensors | Haikang 20 million pixels |

| magnification | 0.88X |

| Display unit | 0.0001 |

| Measurement Accuracy | (±5.0+L/100mm) um |

| Repeatability (m) | ±3.0 |

| camera interface | Gigabit Ethernet (transmission rate: 1G/S) |

| lens | Double telecentric lens |

| lighting system | Transmission System Telecentric Light Transmission (Color: Green) |

| Auxiliary Light source (optional) | Coaxial Light source: Coaxial light drop (Color: White); Low Angle Surface Light source: Movable up and down programmable LED Light source (Color: White) |

| Software version | DISOFOO-S one-click dedicated software |

| Power | AC100-240V 50/60Hz |

| Camera Voltage | Output/rated load DC24V0.6A or less |

| Host Weight (Kg) | 305 |

| The maximum Weight of the workpiece to be tested (Kg) | 5 |

Ipre SC1813 One button fast Measurement Instrument Packing list

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Pendulum damping test method for the determination of film hardness

- How to measure Coating viscosity with ISO cup

- Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- Wet film thickness measurement tool and applicable method

- Understand gas concentration units and sensor types

- Impact strength testing: assessing the rapid deformation of films

- Optical inspection structure for color readers: D/8 D/0 45 °/0

- Swing bar hardness testing: a method for evaluating film hardness

- Apparent viscosity measurement

- Coated steel coatings - Determination of dry-film thickness

SC1813

SC1813

SC3020

SC3020

SC1008

SC1008