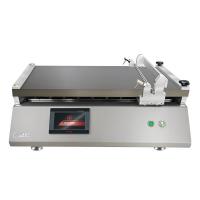

China TBJ-A3-DJ7 Automatic Film Applicator with automatic feeding system

Bar + Vacuum chuck + automatic feeding system, using pneumatic feeding system, effective coating area 850mm * 1000mm, standard 3L volume barrel.

zy

zy-

Domestic (CN) TBJ-B3-DJ4 Automatic Film Applicator Heating type Removable drawdown blade Automatic Film Applicator

$ 8755.00 -

HuiNuo TM3200Pro/15D Automatic Film Applicator bar drawdown blade Coater ECA 100 * 70cm

$ 12070.00 -

HuiNuo TM3000/15 bar drawdown blade Coater ECA 100 * 60cm stepper motor

Login -

China bar Vacuum chuck Coater TBJ-A3-XB with imported bar

$ 2440.00 -

HuiNuo TM3300/17 drawdown Bar & blade heating vacuum adsorption Coater ECA 140 * 120cm

$ 23752.00

TBJ-A3-DJ7 floor-standing automatic coating machine with automatic feeding system is a wire rod scraper heating coating machine with an effective coating area of ââ850mm*1000mm. It comes standard with a 3L volume material barrel and a heating temperature of 180℃. It is often used in laboratories to make films, and is suitable for film making in coatings, inks, polymer materials, films, glues, pressure-sensitive adhesives and other industries.

Optional

zy TBJ-A3-DJ7 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Spreader Accuracy | ±0.003mm |

| Spreader thickness range | 0~10mm |

| Coating speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Coating size | 850mm*1000mm |

| Spreader speed | Digital display, different speeds |

| Coating rod specification | Accuracy 0.001mm (Spreader thickness is determined according to the rod model) |

| Host Power | 220V 50Hz |

| Dimensions | Non-standard customization, subject to the actual order. |

| speed control | Infinitely variable speed |

| Bottom plate material | aluminum alloy |

| Spreader Accuracy | 0.001mm |

| Customizable function | Automatic inking system |

| Customizable function | Jet system device, UV solid inclusion device |

| Feeding principle | Air source pressure flows out |

| Feed Sport Mode | Reciprocating linear motion |

| Feeding back and forth traverse speed | 2-150mm/s |

| spit Volume | Adjustable (by adjusting the air pressure and the operating speed of the discharge port) |

| Shaft drive mode | Timer belt |

| Feeding system air source | 0.6Mpa, can be connected to the trachea of φ 8 (self-matching) |

| Power Voltage of feeding system | 220V,50Hz |

| Tank pressure | Maximum withstand 8Mpa |

| Material of feeding barrel | 304 stainless steel with a wall thickness of 4mm |

| Feeding drum configuration | Safety valve, pressure regulating valve, pressure gauge, relief valve |

| Optional | Leakage tank, substrate fixing fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

| Speed regulation Accuracy | 1mm/s |

| Heating temperature range | RT+~180℃ |

| Temperature Accuracy | ±3℃ |

| Feeding drum Volume | 3L |

zy TBJ-A3-DJ7 Automatic Film Applicator Packing list

Film Applicator X1, imported bar X2, automatic inking system x1, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Scraping machine selection case: film substrate large size high accuracy scraping solution

- Application and Advantages of Coater in Antipyretic Sticker prepative

- Comparison of Different Spreader Methods of Small Coating coater

- Automatic Film Applicator in preparatory self-healing acrylic coatings

- Application and Technical Advantage Analysis of Coater in LR Film

- Review of laboratory film coater technology and selection method

- Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

- Tape laboratory coater technology and film accuracy optimization elements analysis

- Fiberglass hot-melt adhesive coater technical analysis and operation guide

- Application and Technological Innovation of Coater Scratching Hot-melt Adhesive on PET Film

TBJ-A3-DJ7

TBJ-A3-DJ7