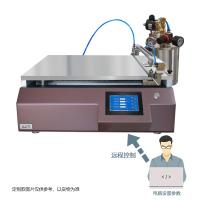

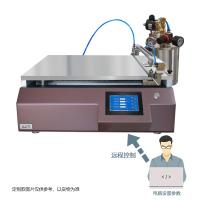

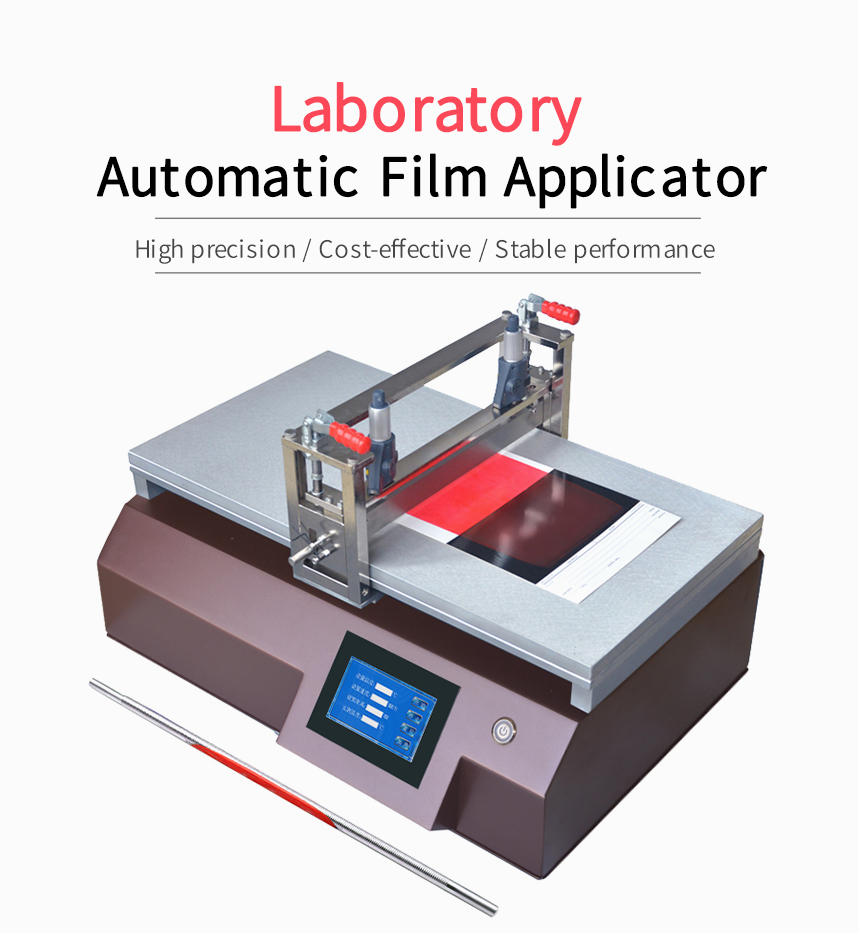

China TBJ-A3-DJ8 Automatic Film Applicator with automatic feeding system

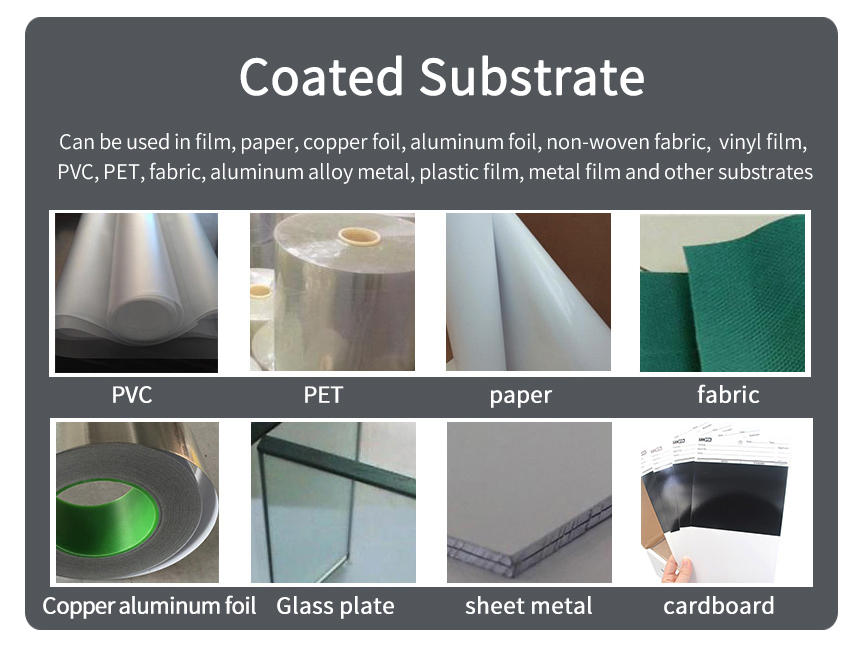

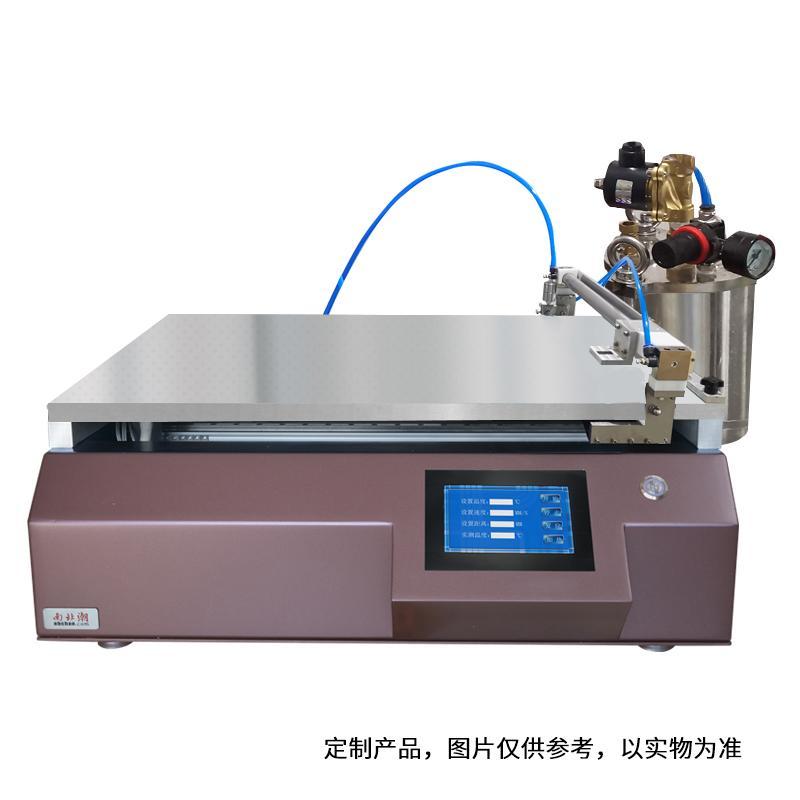

Bar + Vacuum chuck + automatic feeding system, using pneumatic feeding system, effective coating area 850mm * 1000mm, standard 3L volume barrel.

zy

zy-

HuiNuo TM3000/05 Bar & drawdown blade Cabinet Film Applicator Coating size 600 * 800mm

Login -

China Intelligent programmable Coater Heating rod Drawdown blade Film Coater TBJ-B4-DJ10

$ 5124.00 -

HUINUO TM3000 Automatic Film Applicator Mini with Wire rod and Adjustable drawdown blade

$ 2440.00 -

Domestic (CN) TBJ-B1-DJ6 Automatic Film Applicator Intelligent Programmable drawdown blade Coater Automatic feeding

$ 5597.00 -

HuiNuo TM3000Pro/27 Automatic Film Applicator bar drawdown blade Coater

$ 3071.00

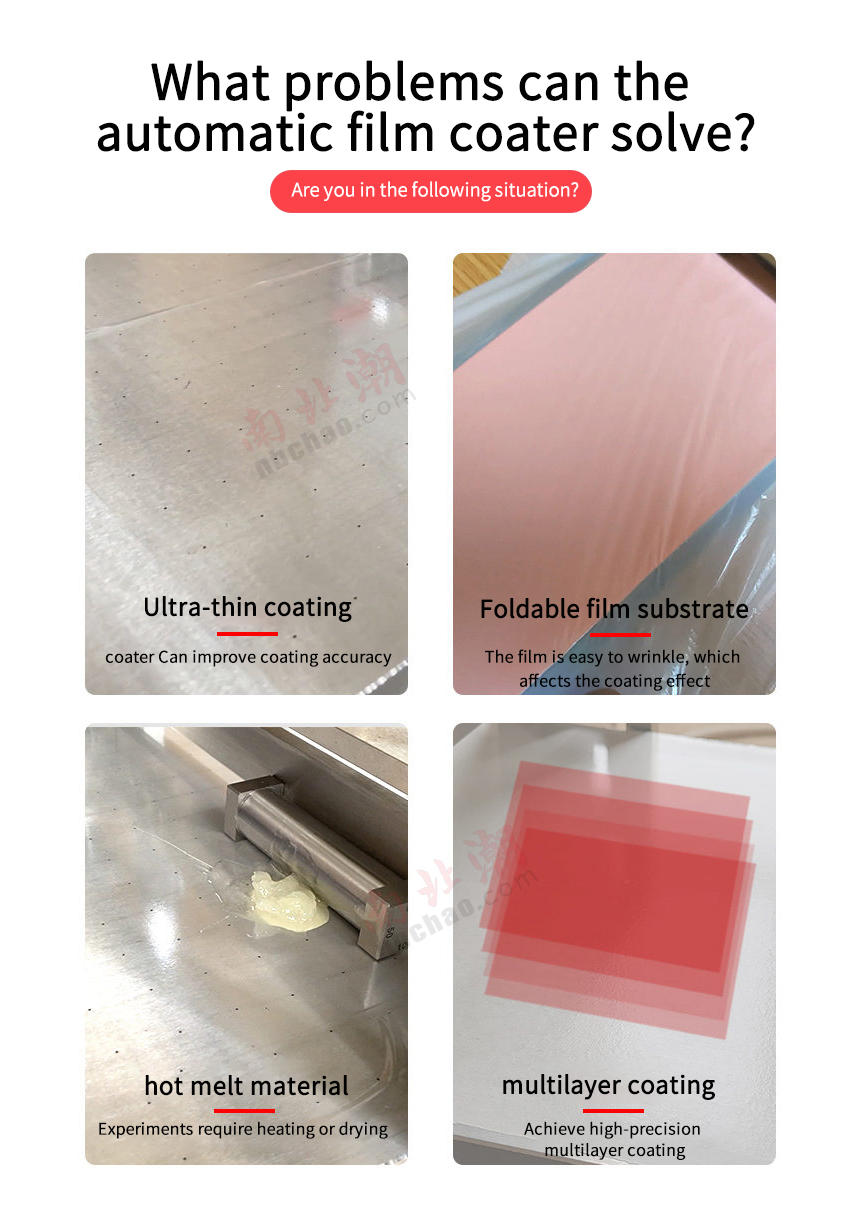

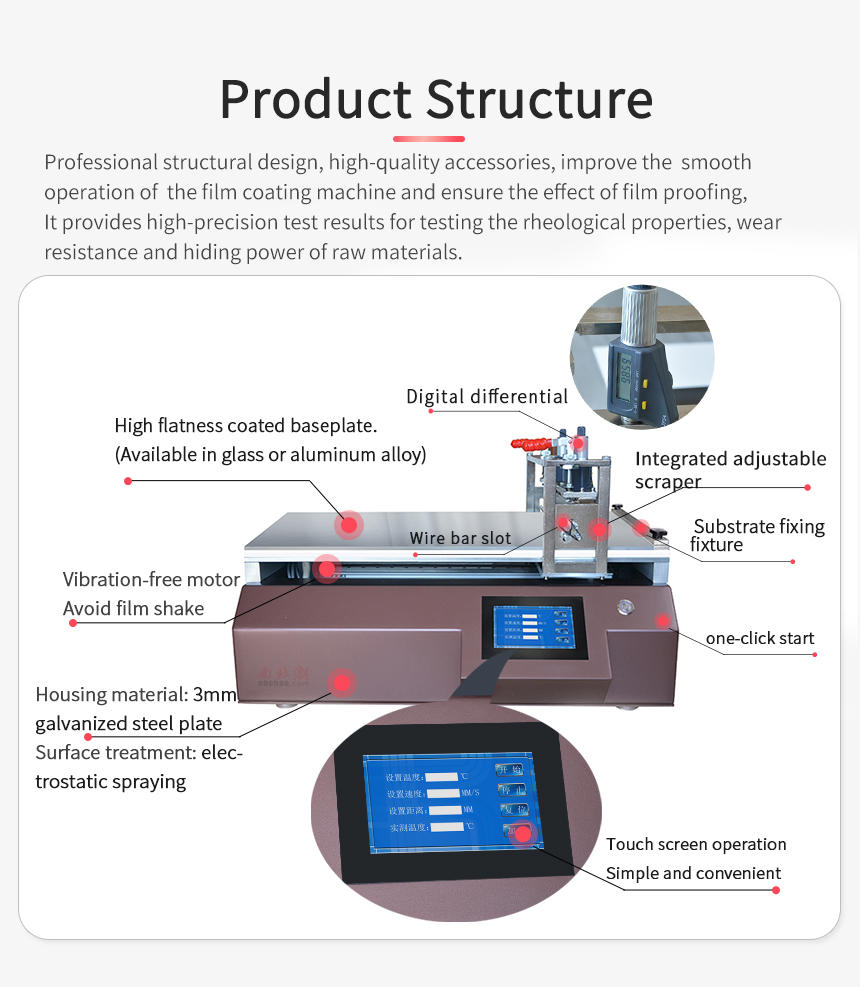

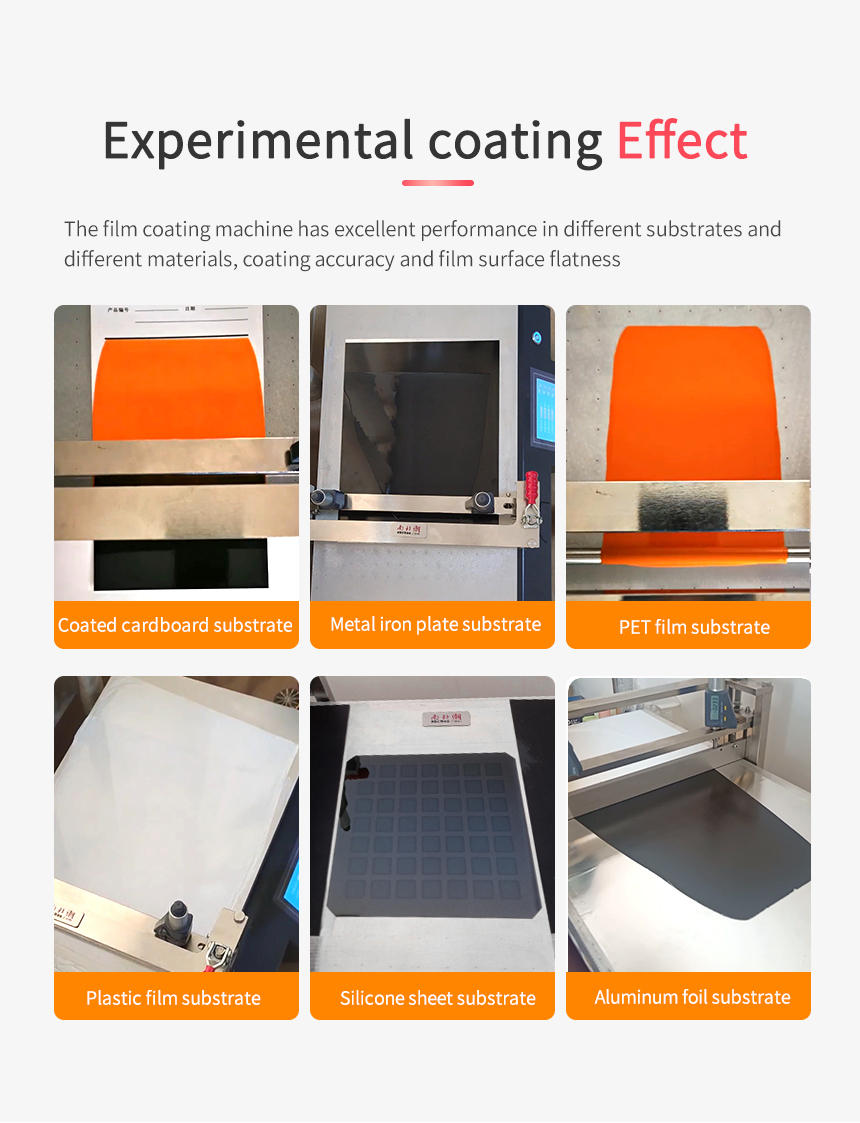

TBJ-A3-DJ8 desktop automatic coating machine with automatic feeding system is a wire rod scraper heating coating machine with an effective coating area of ââ850mm*1000mm. It comes standard with a 3L volume material barrel and a heating temperature of 180℃. It is often used in laboratories to make films, and is suitable for film making in coatings, inks, polymer materials, films, glues, pressure-sensitive adhesives and other industries.

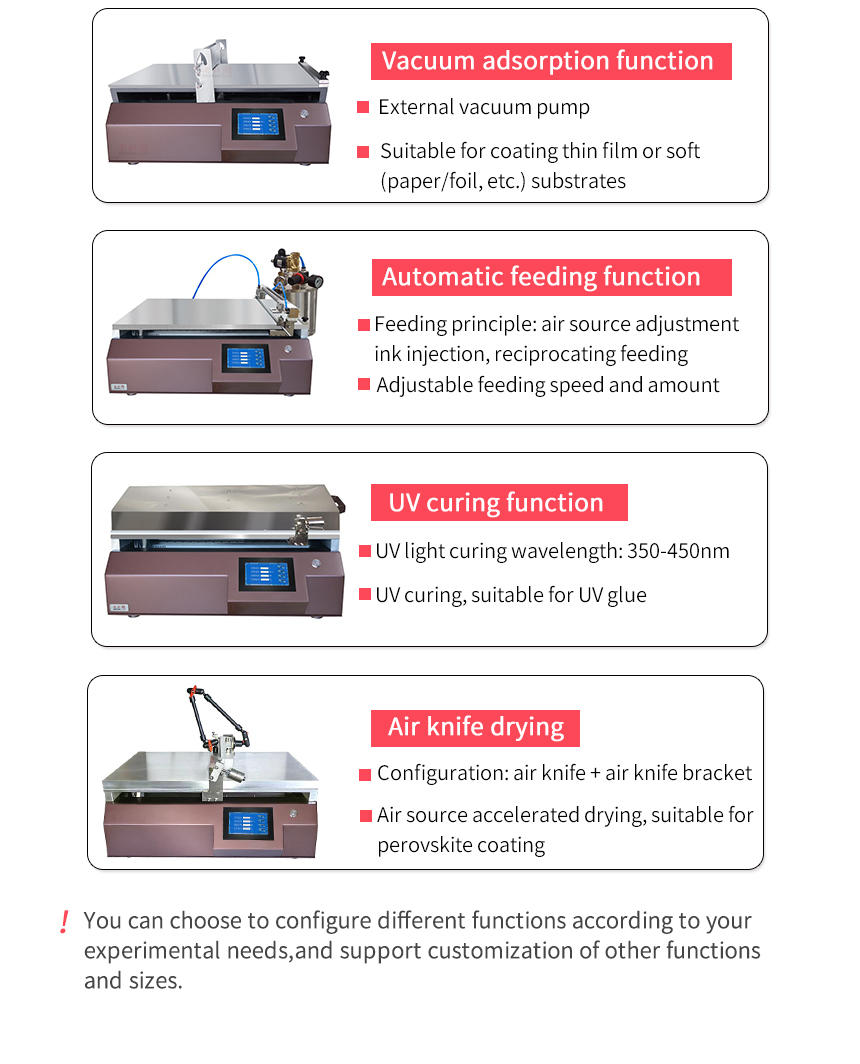

Optional

zy TBJ-A3-DJ8 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Spreader Accuracy | ±0.003mm |

| Spreader thickness range | 0~10mm |

| Coating speed | 5~ 180Mm/s (< 5mm/s can be customized) |

| Coating size | 850mm*1000mm |

| Spreader speed | Digital display, different speeds |

| Coating rod specification | Accuracy 0.001mm (Spreader thickness is determined according to the rod model) |

| Host Power | 220V 50Hz |

| Dimensions | Non-standard customization, subject to the actual order. |

| speed control | Infinitely variable speed |

| Bottom plate material | aluminum alloy |

| Spreader Accuracy | 0.001mm |

| Customizable function | Automatic inking system |

| Customizable function | Jet system device, UV solid inclusion device |

| Feeding principle | Air source pressure flows out |

| Feed Sport Mode | Reciprocating linear motion |

| Feeding back and forth traverse speed | 2-150mm/s |

| spit Volume | Adjustable (by adjusting the air pressure and the operating speed of the discharge port) |

| Shaft drive mode | Timer belt |

| Feeding system air source | 0.6Mpa, can be connected to the trachea of φ 8 (self-matching) |

| Power Voltage of feeding system | 220V,50Hz |

| Tank pressure | Maximum withstand 8Mpa |

| Material of feeding barrel | 304 stainless steel with a wall thickness of 4mm |

| Feeding drum configuration | Safety valve, pressure regulating valve, pressure gauge, relief valve |

| Optional | Leakage tank, substrate fixing fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

| Speed regulation Accuracy | 1mm/s |

| Heating temperature range | RT+~180℃ |

| Temperature Accuracy | ±3℃ |

| Feeding drum Volume | 3L |

zy TBJ-A3-DJ8 Automatic Film Applicator Packing list

Film Applicator X1, imported bar X2, automatic inking system x1, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

- Automatic Film Applicator Technology Introduction and Application

- Review of laboratory film coater technology and selection method

- Resin hot-melt adhesive coater technology depth analysis

- Comparison of Different Spreader Methods of Small Coating coater

- Laboratory proofing coater technology comparison and application review

- Vacuum Film Applicator Technology Analysis: Breaking the Boundary of Surface Coating

- EVA Resin coater technology and operation method detailed explanation

- Spreader Fitting Experiment Machine: Technical Principle, Application and Technical Characteristics

- The Film Applicator You Think Is Not What You Think

TBJ-A3-DJ8

TBJ-A3-DJ8