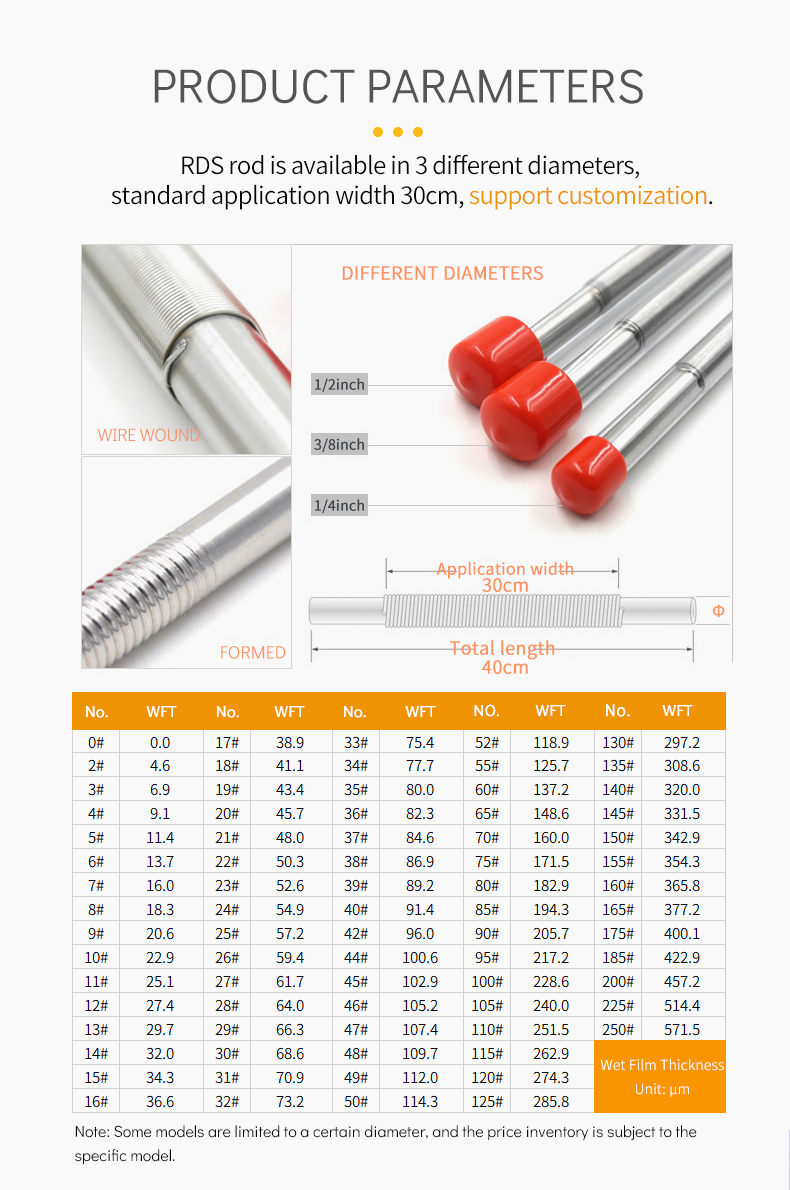

RDS 10 #1/4 "paint rod Applicator film thickness 22.9μm rod diameter 6.35mm

Using formed molding technology, the rod diameter is 6.35mm, and the film can be 22.9μm. It has the characteristics of continuous wire and easy cleaning.

RDS

RDSProduct description

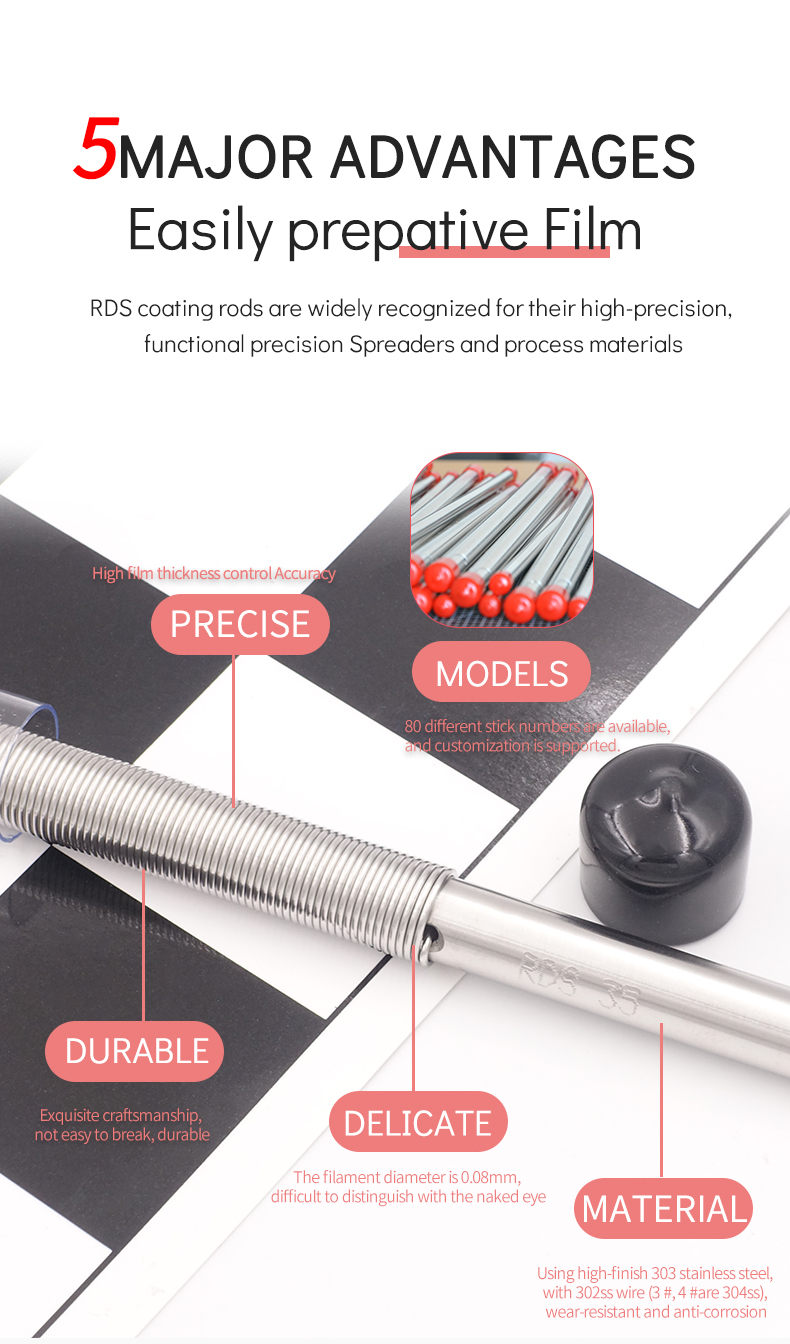

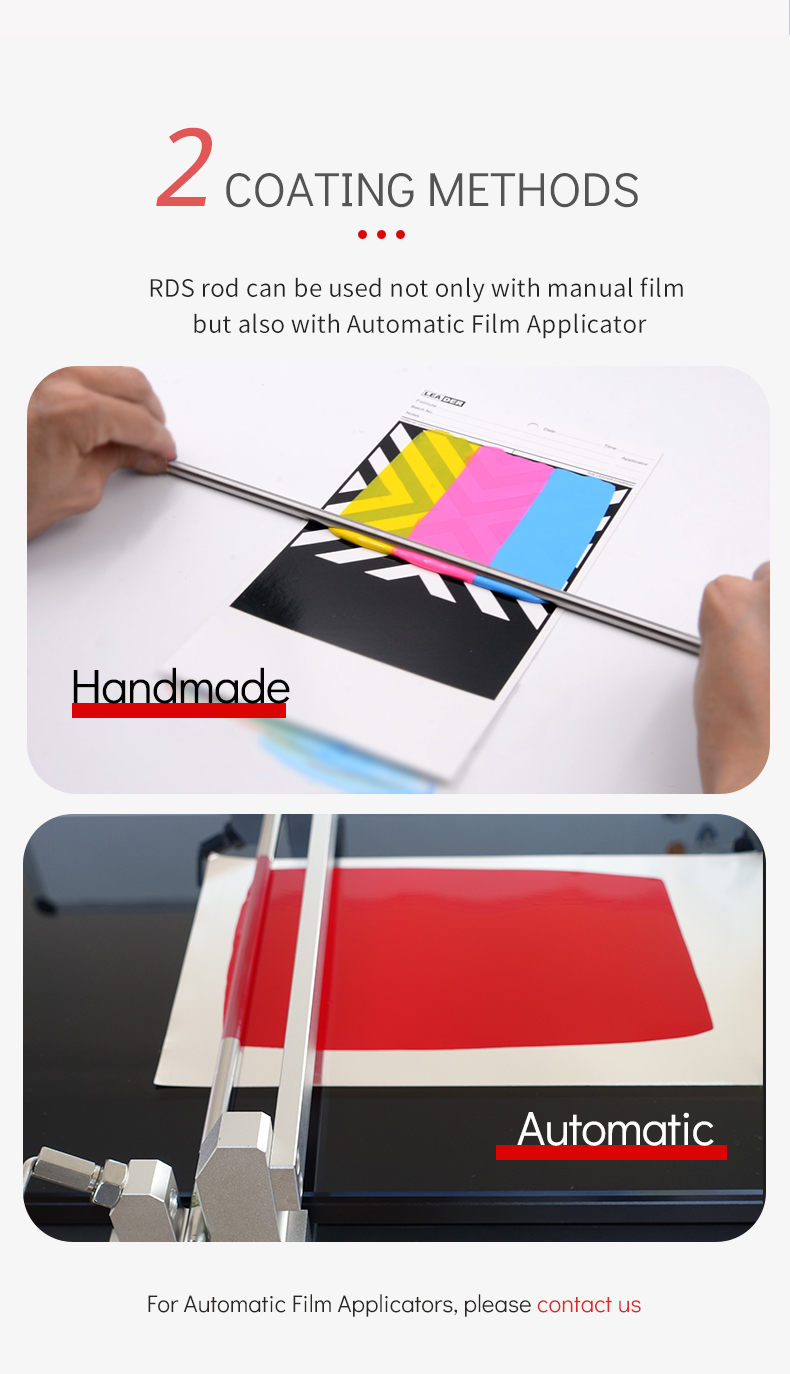

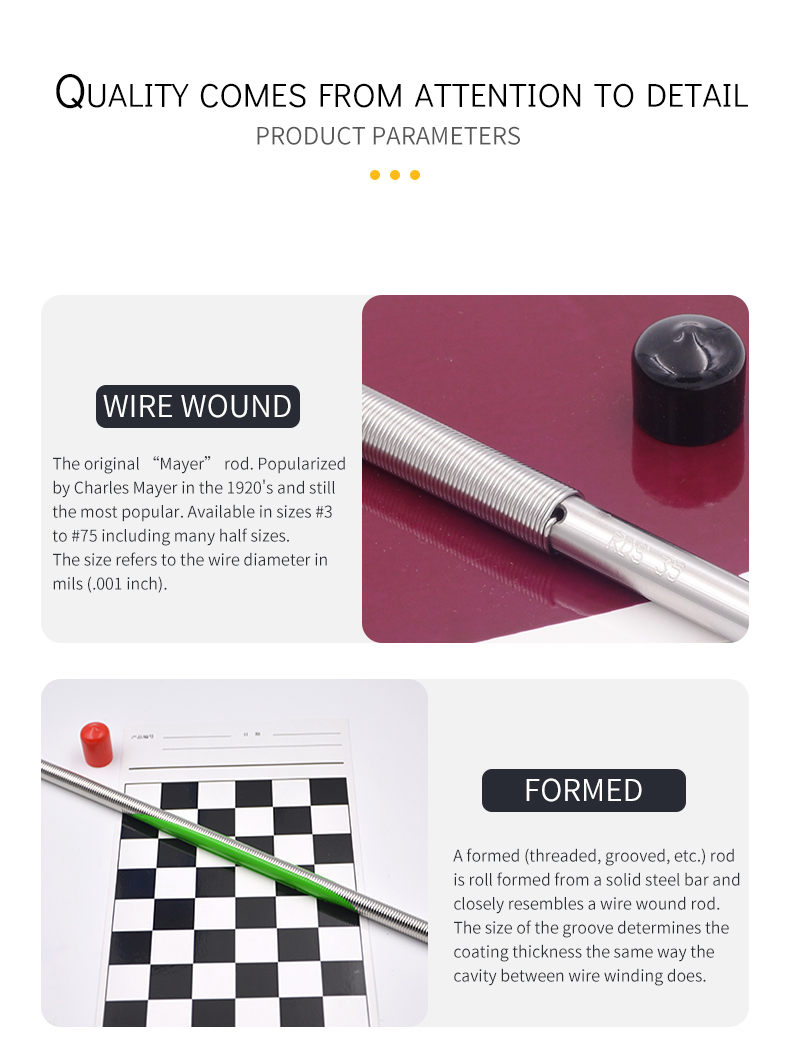

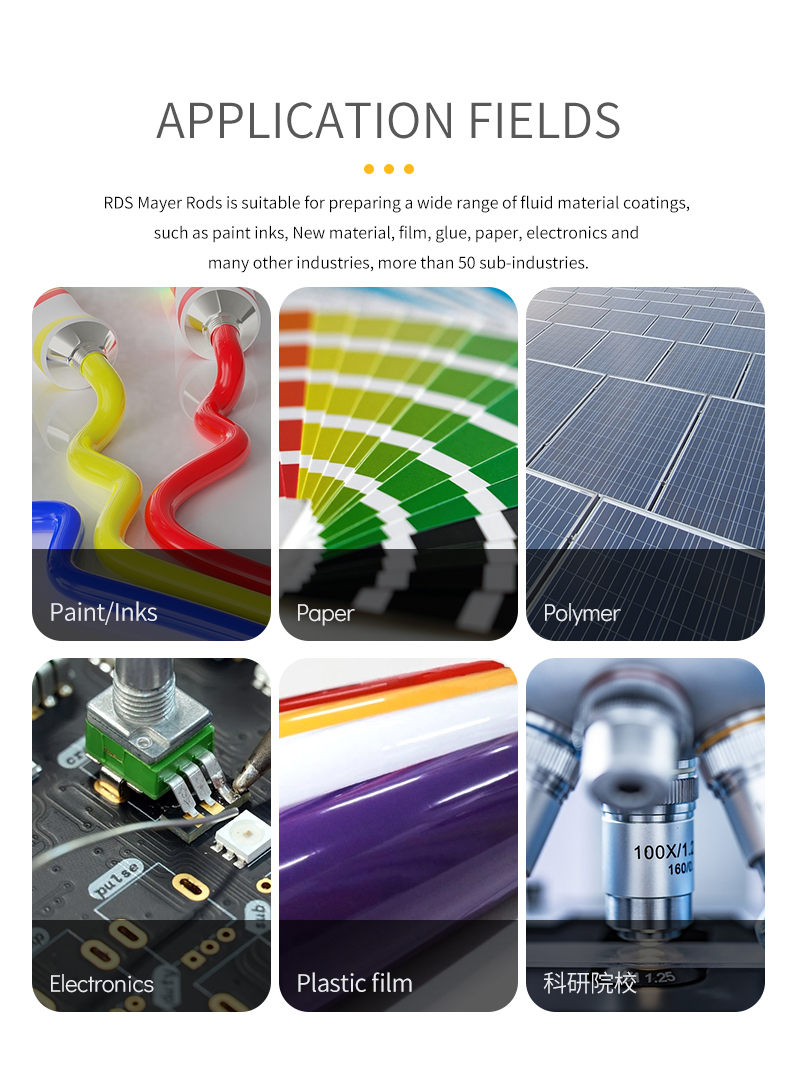

The wet film thickness of the U.S. RDS#10 squeegee rod coating is 22.9 microns, which is divided into two types: wire-wound rods and forming rods. The forming rods are processed on a steel rod through a special extrusion process to have continuous grooves. The advanced coating rod has the advantages of continuous silk and easy cleaning, and is deeply loved by some users in the industry. In addition, the wire winding rod is developed according to the traditional Meyer rod testing principle, and it will be more widely used in the industry. RDS forming rods and wire winding rods of the same type have the same thickness and precision of the coating film, and the difference lies in the coating amount.

RDS 10# 1/4“ Applicator rod 1/4 "Specifications

| LIST | VALUE |

|---|---|

| Production process | formed |

| WFT | 22.9μm |

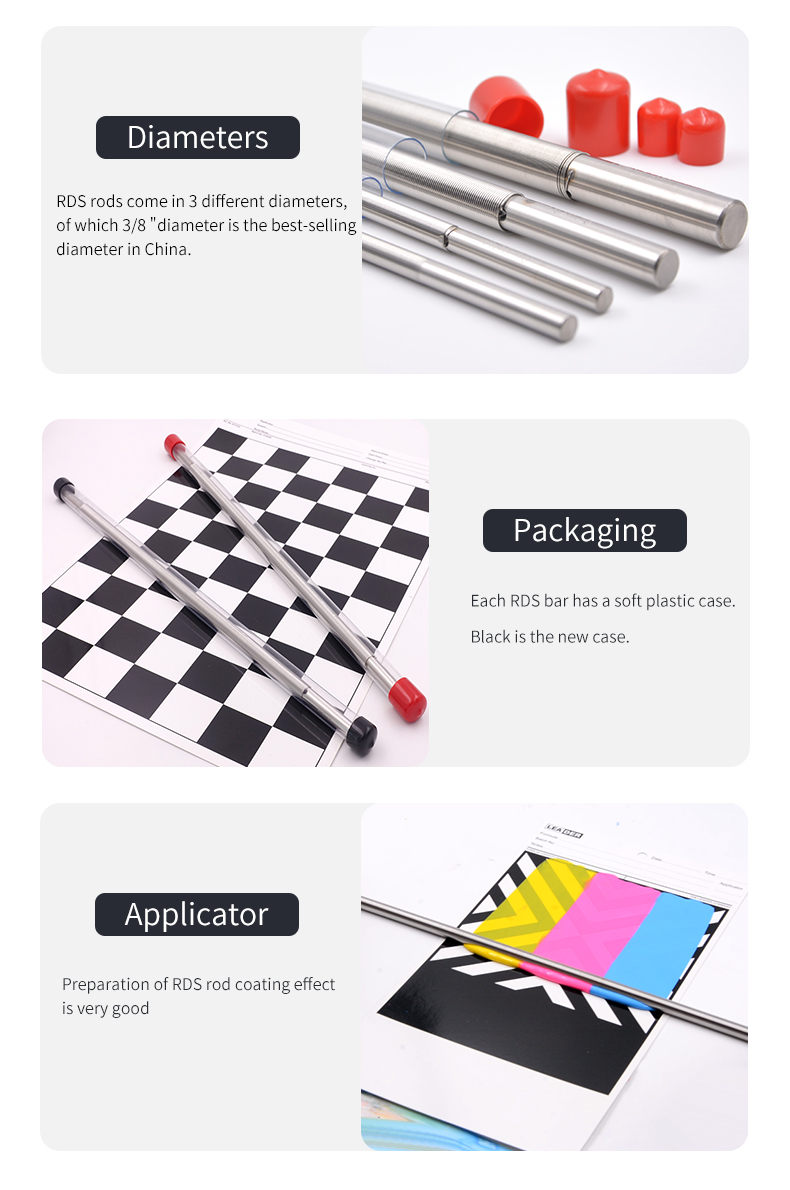

| diameter | 6.35mm |

| Total length | 400mm |

| application width | 300mm |

| Grip Width | 50+50mm |

| material | stainless steel |

RDS 10# 1/4“ Applicator rod 1/4 " Packing list

Stainless Steel Rod X1 Transparent Encasement Hose X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Bar Spreader Technology: Principles, Applications and Advantages over Miscellaneous coating methods

- Application of Mayer Rods in composite coating prepative

- ActiveGB/T 22374-2018

- ActiveGB/T 1727-2021

- ActiveGB/T 7044-2022

- ActiveGB/T 23997-2009

- ActiveHG/T 20720-2020

- ActiveHG/T 5370-2018

- ActiveHG/T 3951-2007

- ActiveHG/T 3948-2007

- AbolishGB/T 13217.1-2009

- ActiveASTM D823-2018

- AbolishGB/T 9270-1988

10# 1/4“

10# 1/4“

10# 3/8"

10# 3/8"

10# 3/8"

10# 3/8"