Japanese OSP L60 Spreader handle, used with OSP L60 series short stick

Use with OSP L60 series short rods

OSP

OSPOSP L60 handle

This handle is a handle for OSP L60 series short bars. The handle is a new process specially designed by OSP to reduce the problem of uneven coating caused by uneven manual pressure when scraping the film by a specific weight.

Note: The price is only a single handle price, excluding the scraper, please purchase the coating set if you need the scraper,The handles have an oxide and electroplating layer and cannot be directly soaked in corrosive solvents for cleaning.

OSP scraper L60 model comparison table

Bar number (click) | Wet film thickness | Stick number | Wet film thickness | Stick number | Wet film thickness | Stick number | Wet film thickness |

| OSP-00/60 | 0μm | OSP-09/60 | 9μm | OSP-30 /60 | 30μm | OSP-100/60 | 100μm |

| OSP-1.5/60 | 1.5μm | OSP-10/60 | 10μm | OSP-35/60 | 35μm | OSP-120/60 | 120μm |

| OSP-02/60 | 2μm | OSP-12/60 | 12μm | OSP-40/60 | 40μm | OSP-150/60 | 150μm |

| OSP-03/60 | 3μm | OSP-13/60 | 13μm | OSP-42/60 | 42μm | ||

| OSP-04/60 | 4μm | OSP-15/60 | 15μm | OSP-47/60 | 47μm | ||

| OSP-05/60 | 5μm | OSP-17/60 | 17μm | OSP-50/60 | 50μm | ||

| OSP-06/60 | 6μm | OSP-18/60 | 18μm | OSP-52/60 | 52μm | ||

| OSP-07/60 | 7μm | OSP-22/60 | 22μm | OSP-60/60 | 60μm | ||

| OSP-08/60 | 8μm | OSP-25/60 | 25μm | OSP-80/60 | 80μm |

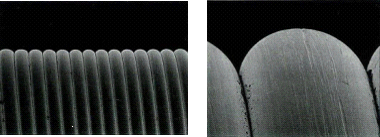

OSP scraper compared with traditional stainless steel wire rod

The traditional stainless steel wire rod is coated by winding a thin steel wire on the surface of the steel rod, and the thin steel wire on the surface is easy to loosen and break, and it is not easy to clean, and it cannot be coated with ultra-thin film.

Stainless steel wire rodTraditional stainless steel wire rod is insufficient:

★ The steel wire is easy to loosen and break

★ Not easy to clean

★ Ultra-thin film coating is not possible

Is there a product that can replace the wire scraper?

After several improvements, OSP finally succeeded in developing the D-BAR. It was officially launched into the market in 2001.

Advantages of OSP scraper:

In order to solve the above problems, OSP has developed a new extruded stainless steel scraper. OSP stainless steel scraper uses precision mold and cold extrusion technology to process a concave and convex wavy curve on the surface of the steel bar, which has the same coating effect as the traditional stainless steel wire rod. However, because there is no thin steel wire wound on its surface, there is no worry about the steel wire loosening and breaking. Moreover, the curved lubrication of the surface is smooth, making it very easy to clean. The most commendable thing is that the OSP stainless steel scraper breaks through the limit of the traditional stainless steel wire rod and can coat the wet film with a thickness of only 2um, which solves the problem of ultra-thin film coating in one fell swoop.

OSP stainless steel wire rod

★ There is no worry about the wire being loose and broken

★ Very easy to clean

★ Ultra-thin film coating is possible

It won't come loose, it won't break

The principle of plastic deformation of metal is used to roll various mountain shapes on the surface of the steel rod.

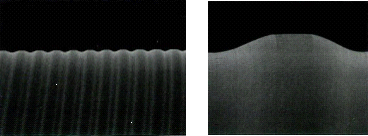

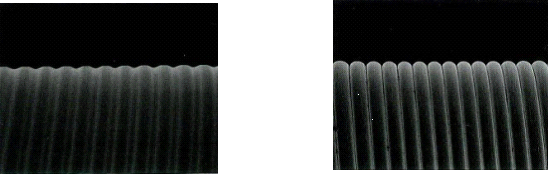

Comparison of cleaning results:

OSP Scraper Conventional filament wound type wire rod applicator

Coating solution: water-based synthetic resin paint

Cleaning method: Soak in alcohol for 24 hours, then wipe with a cloth.

An easy-to-clean, non-clogging surface shape

OSP wire bar applicator Wire scraper

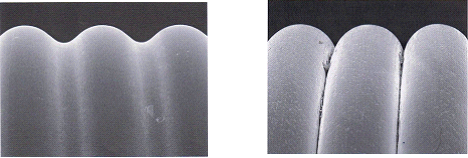

You can choose a good mountain type according to the substrate and coating solution

Standard mountain type (S type)

Standard mountain type (S type)

It can solve various problems in coating processing

A combination of left and right spiral directions

Prevent the mixing of air bubbles and reduce the loss of substrate caused by air bubble mixing.

Square eye lines

Mainly used in calendering rollers

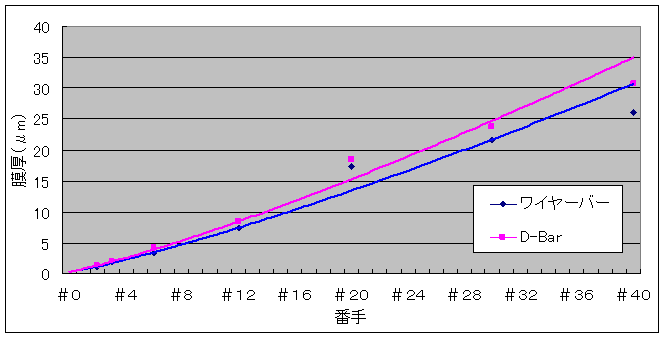

Coating weight comparison:

Difference in coating weight: The bottom of the D-Bar mountain type is wider than that of a conventional Steel Wire Drawdown Rod, so in general, the coating weight of the D-Bar is larger.

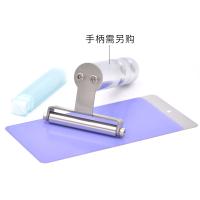

OSP scraper L60 series handle real shot

Schematic diagram of L60 doctor blade coating

OSP L60 handleSpecifications

| LIST | VALUE |

|---|---|

| Adaptive rod | OSP 60mm long wire rod |

| Handle material | Stainless Steel + Hard Chromium Eletroplating |

| Fixture material | stainless steel |

| Screw material | stainless steel |

| Precautions | Can not be directly soaked in corrosion solvent cleaning |

OSP L60 handle Packing list

L60 handle x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- The experimental case of OSP Mayer Rods at inks Moulding [with video]

- What problems should I pay attention to when buying a wire rod applicator?

- Nanbei Chao technical engineer tells you: What are often asked when buying a wire rod?

- Frequently Asked Questions for Inventory 2022 Lines, Issue 1

- What wire rod applicator have users in the aluminum profile industry bought?

- Preparation of Ultrafine Silver Nanowire Transparent Conductive Films by Coating Machine + Wire Rod

- What kind of bar applicator have customers in the adhesive industry bought?

- Preparation of fluorescent anti-counterfeiting gravure ink with ink proofing machine

- What are the models of popular bar applicators?

- Which wire rod applicators have the printing industry purchased?

L60

L60

OSP-150/60

OSP-150/60