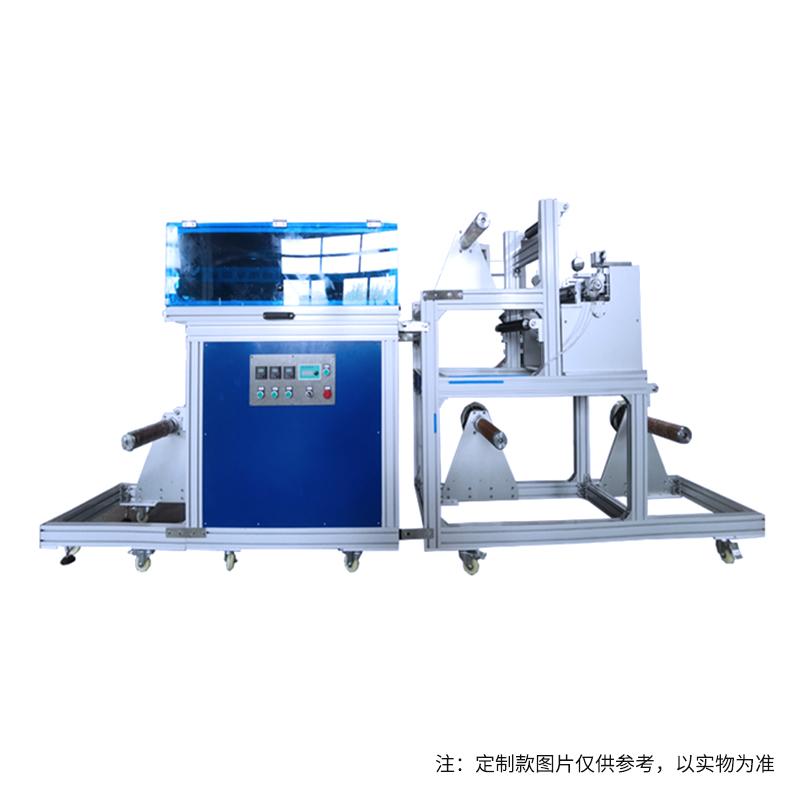

NBC-ZYTJ300 special Coater Spreader compound slitting integration

Coating + compounding + cutting, the product size error is less than 2%, roll coating process, thickness range 0~3mm, special and patch Spreader.

Factory

Factory-

HuiNuo JTM-300UV/0.6 Small continuous Coater UV UV curing Full electric control 0.01mm Spreader thickness

$ 9544.00 -

CHINA Small hot-melt adhesive Continuous Film Applicator NBC-6025H Continuous Coater, baseplate heating + drawdown blade heating

$ 5281.00 -

Factory Direct Rva-04/300 Micro Concave Roll Film Applicator 300mm Effective Spreader Width

$ 23752.00 -

Rxg-01/500sc sheet continuous automatic glue injection machine, spray coating machine

$ 39539.00 -

CHINA Micro Coil Automatic Spraying and Coating Machine TBJ-JCPT-DJ1 Customized

$ 19016.00

Features

1. The coating, compounding, and cutting processes in production are all automatically handled by the equipment. The operation is simple and convenient, and materials are added automatically. (The cutting size can be customized in advance)

2. Most of the equipment used are high-precision parts, which can ensure that the product size error is less than 2%, the patch position error is less than 3%, and the yield rate is as high as 99%;

3. The equipment operates basically without noise, which can improve the Operating Environment;

4. The power of the equipment comes from a high-performance speed-regulating motor, and the efficiency can reach 70~100 pieces/minute (product width 5OMM, effective coating width 300mm). The smaller the product size, the higher the efficiency;

5. Equipment reduces maintenance costs.

Factory NBC-ZYTJ300a Special coater for patchSpecifications

| LIST | VALUE |

|---|---|

| Coating method | Roller coating |

| Thickness range | 0-3mm |

| Accuracy | ±0.005mm |

| Device size | 2500*800*1750mm |

| Motor efficiency | 70~100 tablets/min |

| Effective application width | 300mm |

| dimensional error | Less than 2% |

| patch position error | Less than 3% |

| yield | 99% |

| Coating size | Max.300mm |

Factory NBC-ZYTJ300a Special coater for patch Packing list

machine x1, manual x1, certificate x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Laboratory automatic coating machine selection considerations

- Moulding application of small coater in high gloss film

- Comparison of Different Spreader Methods of Small Coating coater

- Teach you to choose the right laboratory wire rod coater

- Tape laboratory coater technology and film accuracy optimization elements analysis

- Application of Slot die coaters in Lithium Battery Coating

- Application and Technical Advantage Analysis of Coater in LR Film

- Application of laboratory coater on release paper with glue [video demonstration]

- Selection and operation process of polymer structure glue coater

- Application, Characteristics and Selection Method of doctor blade coater

NBC-ZYTJ300a

NBC-ZYTJ300a