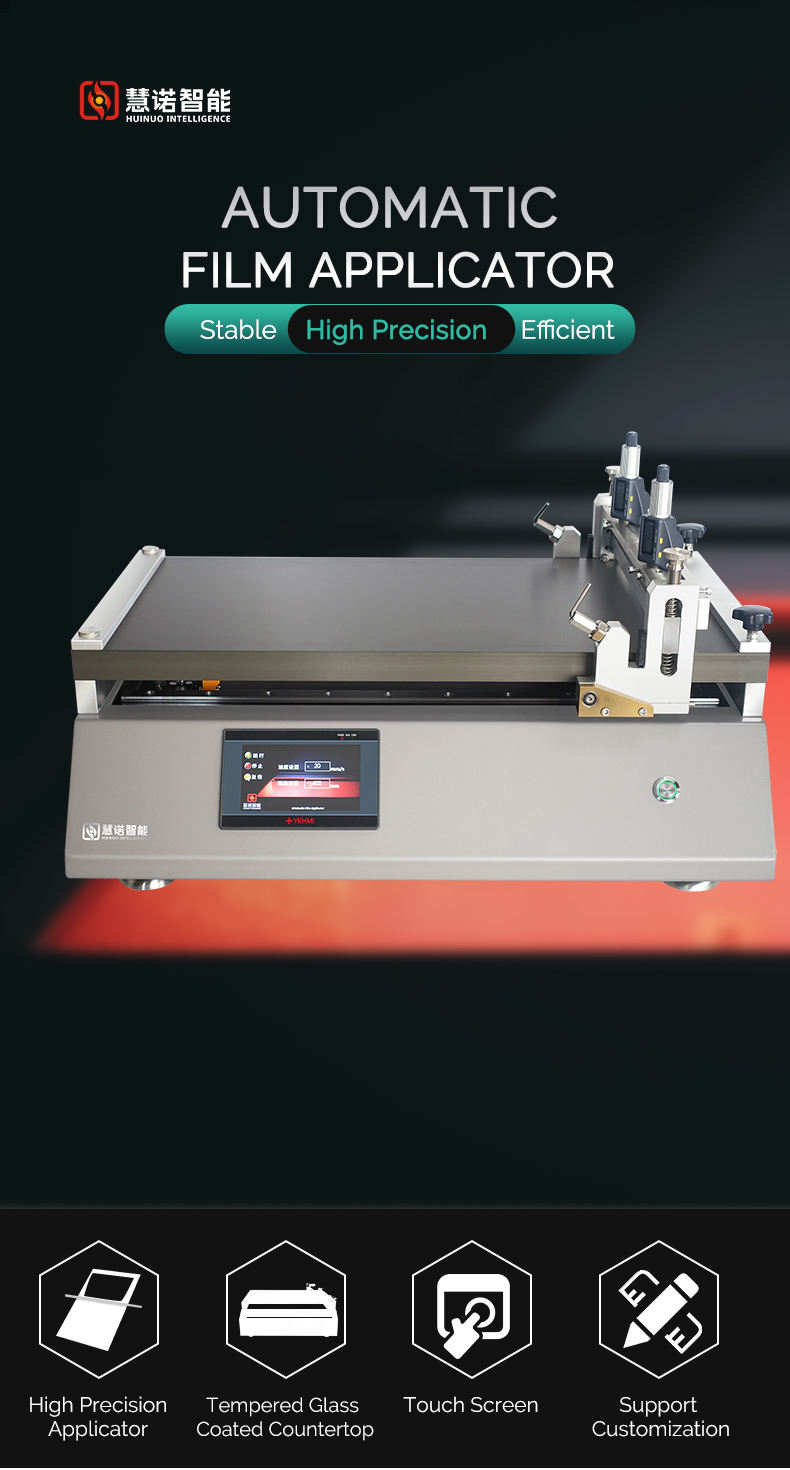

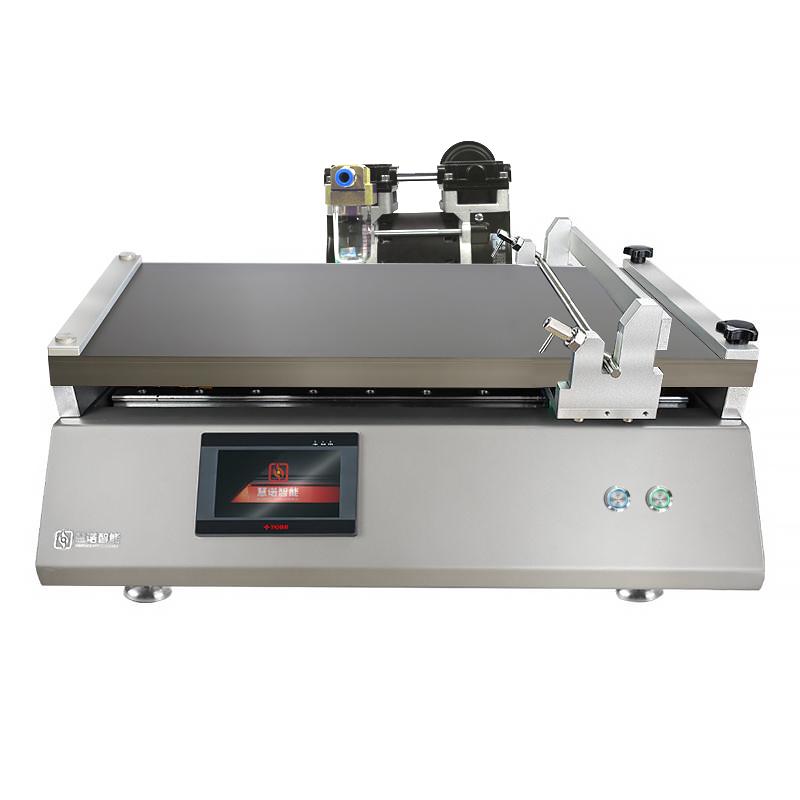

TM1300pro High-precision Laboratory Wire Bar Coater with Heated Vacuum Table

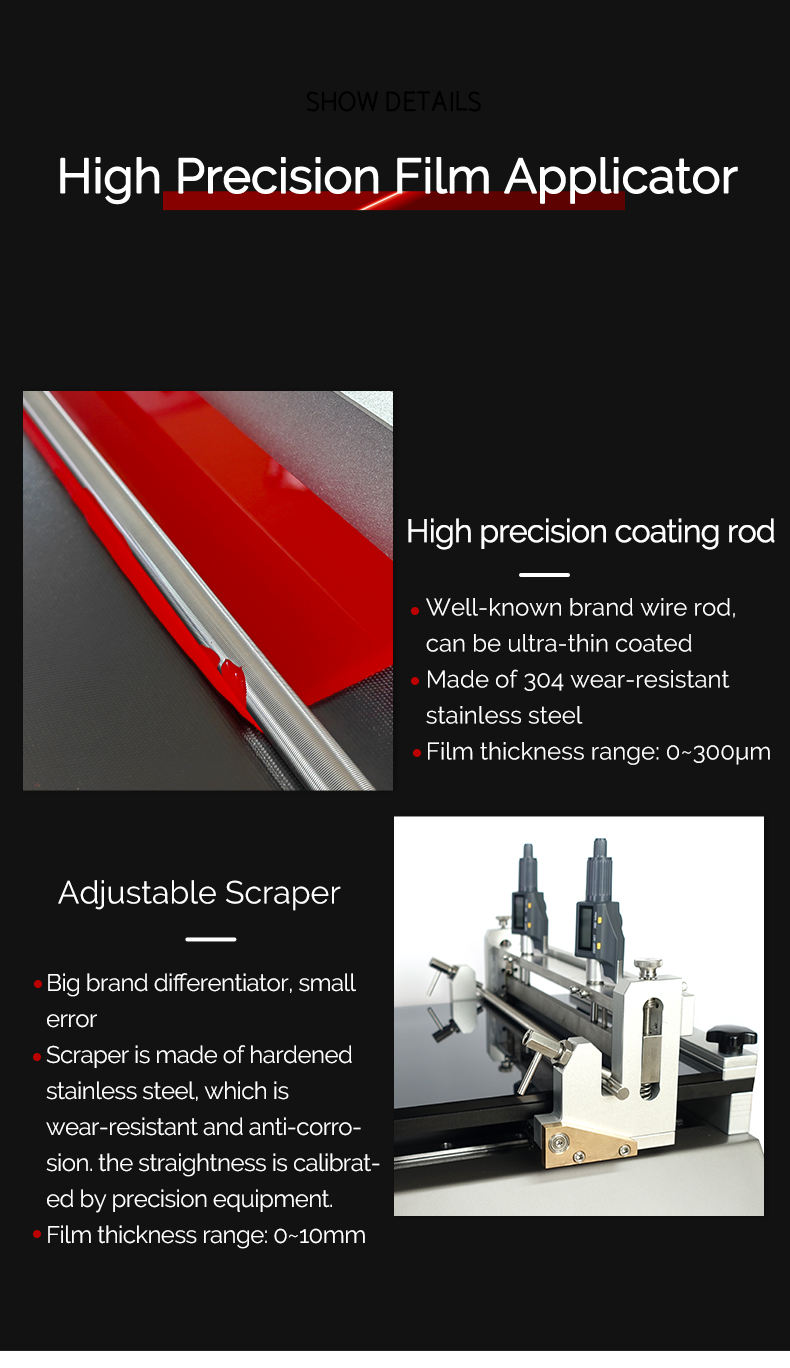

Wire rod Spreader, with heating function, servo motor, simple wire rod groove design, wire rod installation is simple, Smoothness hardening treatment aluminum alloy baseplate, wear resistance and scratch resistance.

-

China Perovskite Experimental Film Applicator TBJ-X3-ABO2 with imported bar with air knife + air knife double bracket

$ 5439.00 -

HuiNuo TM3300/13 drawdown Bar & Blade heating vacuum adsorption Coater customized 500 * 600mm

$ 7176.00 -

HuiNuo TM3100AK/02 Perovskite Laboratory Film Applicator drawdown Bar & blade heating Coater

$ 4176.00 -

HUINUO TM2200Pro/02 drawdown blade vacuum adsorption Small Film Applicator ECA 500 * 600mm

$ 6071.00 -

Huino TM3300Pro/45 Automatic Film Applicator metering rod & doctor blade Spreader Heating vacuum adsorption Effective Spreader area 100 * 60cm

$ 17437.00

HuiNuo TM1300pro Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

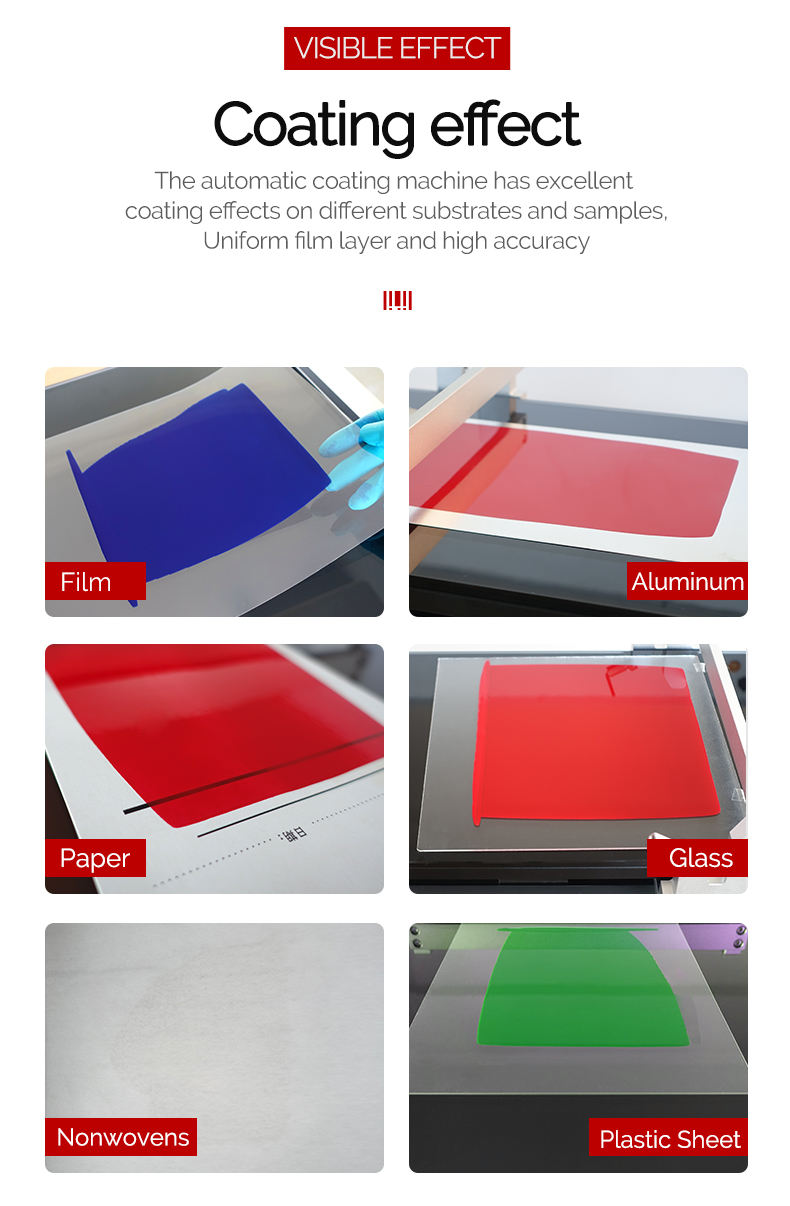

| Coating method | Rod |

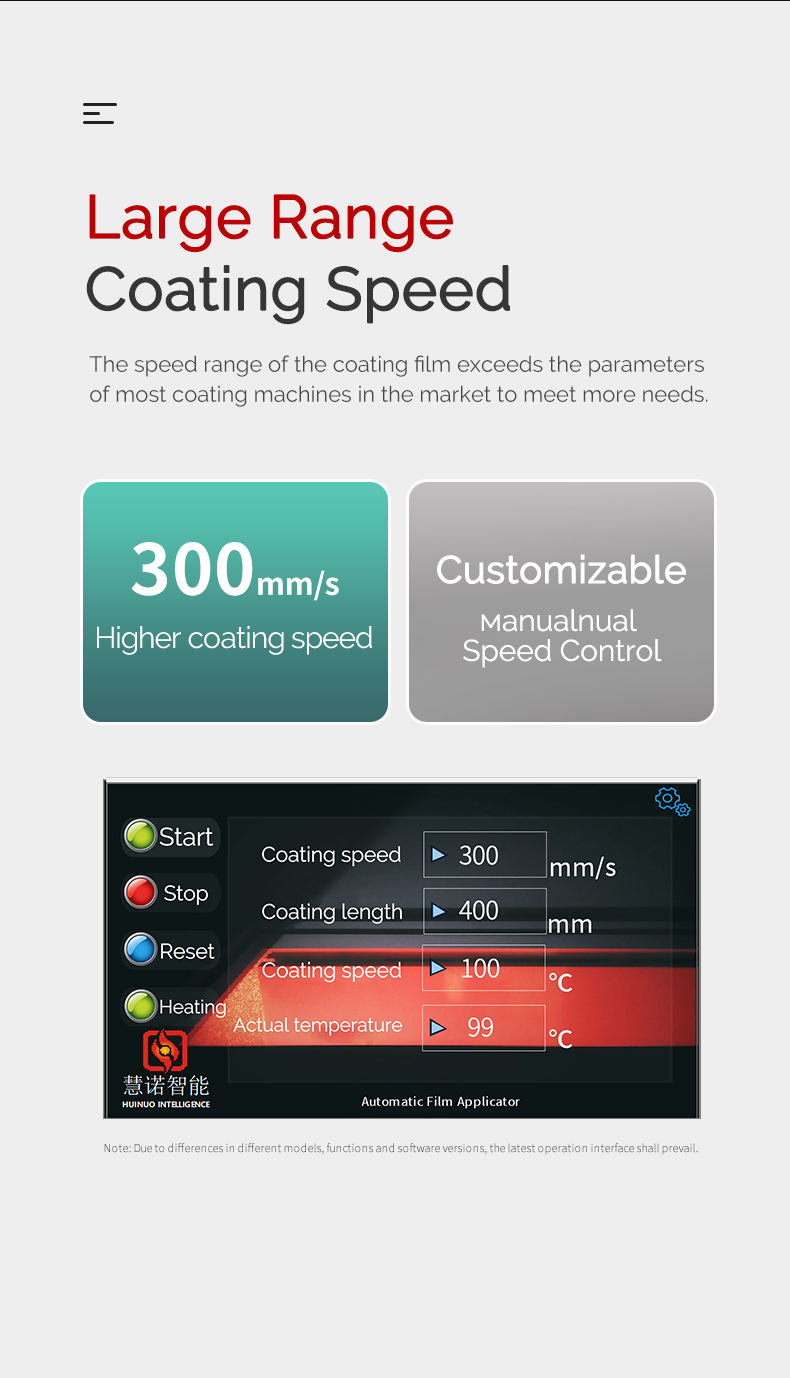

| Coating speed | 1~ 300Mm/s stepless speed regulation (can be customized) |

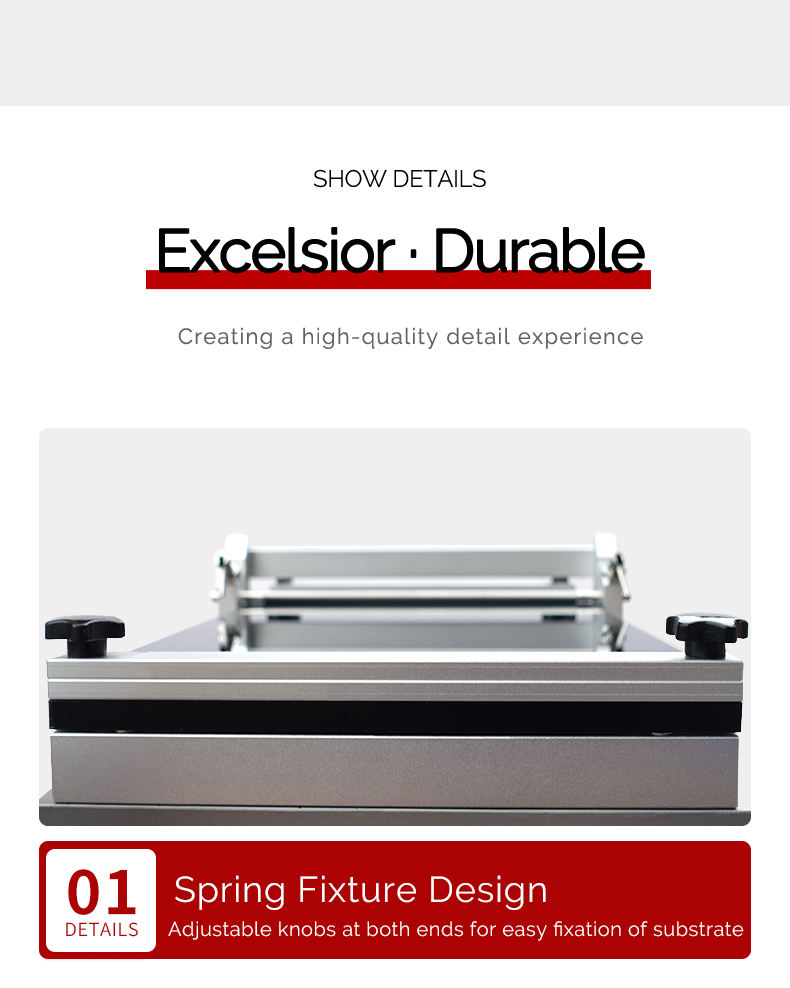

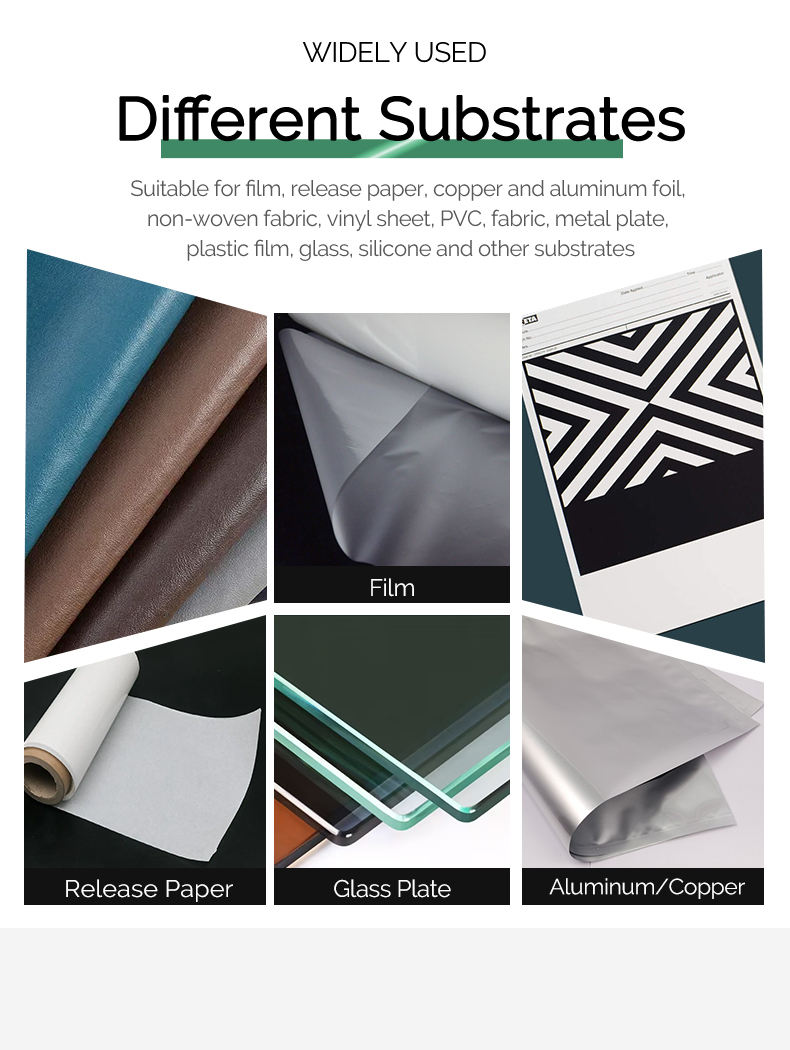

| Substrate clamping method | Vacuum adsorption + fixture |

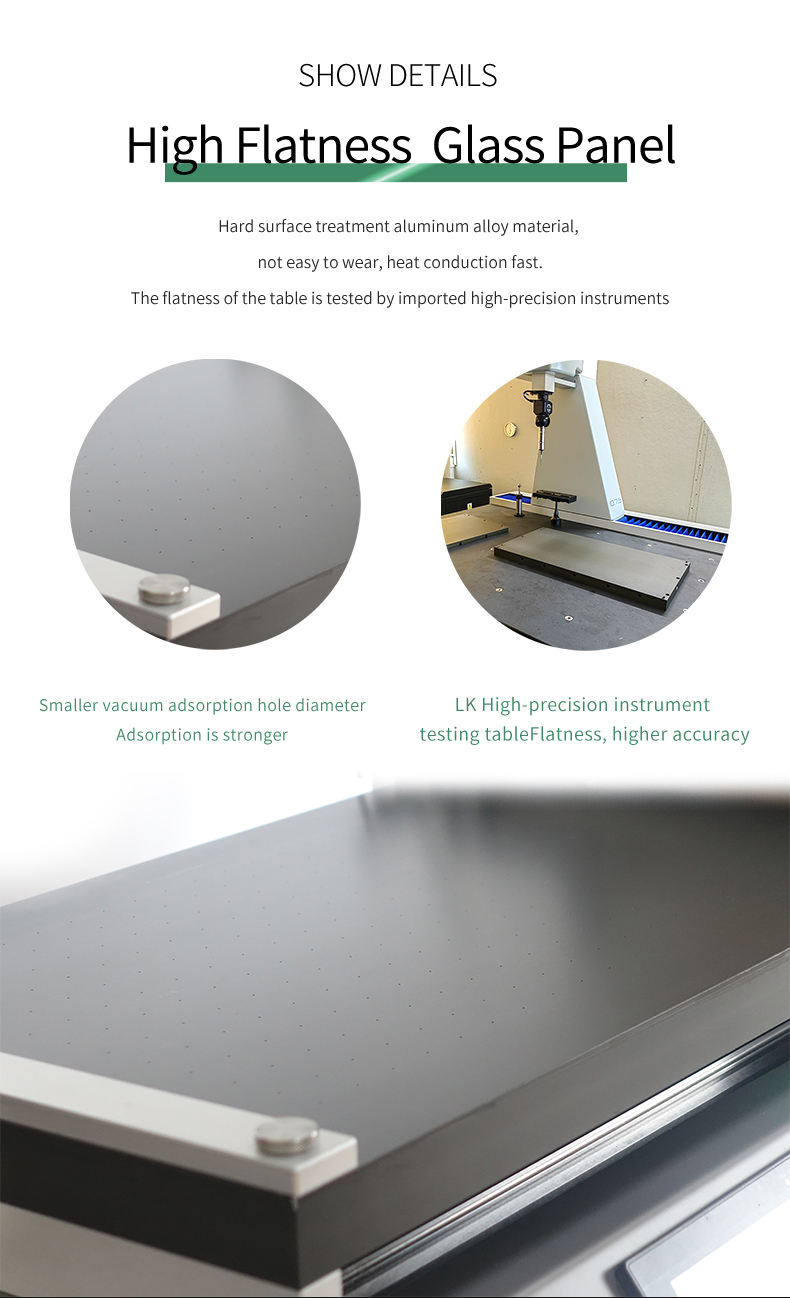

| Coating table material | Surface hard treatment aluminum alloy |

| Coating table size | 600*300mm |

| Effective coating Area | 400 * 300Mm (can be customized) |

| Mayer Rod Thickness Range | Different bar numbers have different thicknesses, with high-precision imported bars |

| Mayer Rod Accuracy | ±0.001mm |

| Vacuum Area | 400 * 300Mm (can be customized) |

| vacuum aperture | Φ0.8mm |

| Vacuum hole spacing | 20*20mm |

| Pumping Speed | 5.4m3/h |

| Ultimate Vacuum | 50KPa |

| Vacuum Pump Power | 180W |

| Vacuum pump Weight | 7.1kg |

| Heating mode | Mica sheet heating (optional graphene heating, faster thermal conductivity) |

| Heating Temperature range | RT +~ 180 ℃ (higher temperature can be customized) |

| Temperature Uniformity | ±1℃ |

| Drive motor | Servo motor |

| Operating language | Chinese (can be customized in English) |

| Display | Color LCD touch screen |

| Host Power Supply | 220V/50HZ (can be customized 110V/60HZ) |

| Power | 2000W |

HuiNuo TM1300pro Automatic Film Applicator Packing list

Whole machine X1, manual X1, fixture X1, doctor blade x1, imported wire rod X1, certificate X1, vacuum pump X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

HuiNuo

HuiNuo TM1300pro

TM1300pro

TM1300

TM1300

TM2300

TM2300