Pharmaceutical Patch Coater Rxg-01/300uvcx pro Spreader cutting Coater

Process: unwinding - Spreader - film laminating - slitting, material roll diameter 3 inches, servo system, hob type cross cutting, effective application width 300mm.

Factory

Factory-

CHINA NBC-XF500 pet slot die roll to roll Film Applicator Spreader Width 500mm

$ 60062.00 -

CHINA Twin roll extrusion Coater TBJ-SDJY-DJ formed Automatic Film Applicator

$ 4018.00 -

Rgd-00/400cs hot-melt adhesive coating and cutting machine, Coil Automatic Film Applicator

$ 36382.00 -

CHINA immersion coil drying air-cooled slitting machine Rdc-01/500cs dipping coating machine

$ 34803.00 -

CHINA Automatic immersion coil Coater Rjy-01/500dc double roll extrusion

Login

Introduction

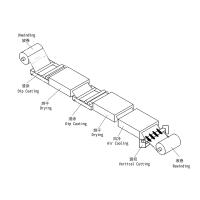

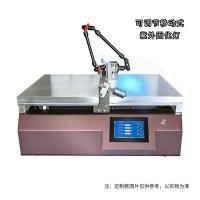

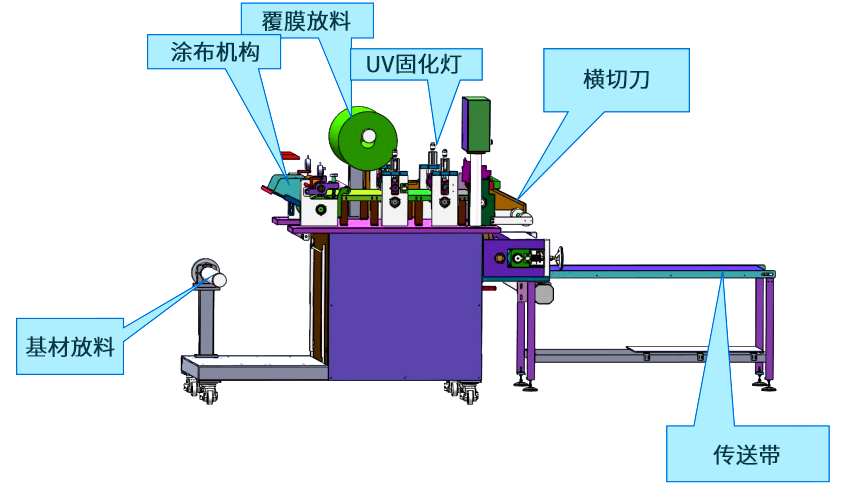

The special pilot film coating machine for pharmaceutical patches is an automatic coil coating machine integrating coating, cutting, drying and unwinding, which is suitable for plastering, pharmaceutical patches and hydrogel film coating.It is often used in medical, cosmetic, sanitary products and other fields. This coater is equipped with a slitting function and supports UV curing.

Product structure diagram

Factory Rxg-01/300uvcx pro Spreader cutting machineSpecifications

| LIST | VALUE |

|---|---|

| production speed | 0-5m/min |

| Effective application width | ≤300mm |

| Coil diameter | 3 inches. |

| Power | 1.4KW |

| Power supply Voltage | Three-phase 220V |

| Motor type | Control system |

| cross-cutting | Hob type (servo system) |

| unroll | With tension control |

| Control mode | Touch screen (Kunlun Tongtai) |

| Vertical cutter installation | 3 |

| Toolbox | 1 (with: Thickness gauge, screw driver, tracheal interface 1) |

| inflated shaft | 2 |

| Spreader process | Unwinding → Spreader → film laminating → slitting |

Factory Rxg-01/300uvcx pro Spreader cutting machine Packing list

Host x1, Manual x1, Encasement List x1, Certificate of Conformity x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Discuss the key technologies of small roll-to-roll coater: Spreader head, roller, drive and drying

- Overview and comparative analysis of roll-to-roll coater and double-sided coater technology

- Technical introduction of PU film coater

- Analysis on the Technology of Spreader

- Comparative Analysis of Small Spreader and Traditional Roll-to-Roll Coater

- Small roll-to-roll coaters: an in-depth analysis and maintenance guide for common failures and solutions

- Overview and skills of laboratory roll-to-roll coater technology

- Deep analysis of tension control principle of coater coil

- Automatic Film Applicator technology analysis

- Application of Coil Coater Spreader on Non-woven Fabric

Rxg-01/300uvcx pro

Rxg-01/300uvcx pro

NBC-ZYTJ500

NBC-ZYTJ500