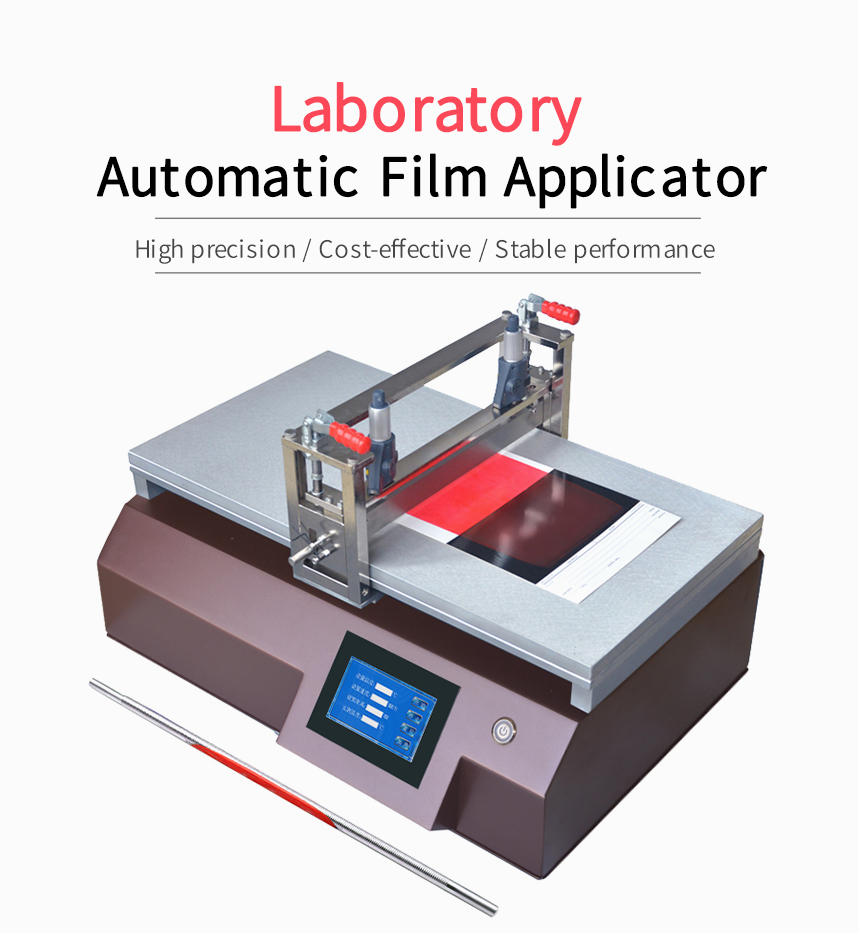

China Perovskite Experimental Film Applicator TBJ-B4-ABO drawdown Bar & blade heating + air knife + air knife bracket

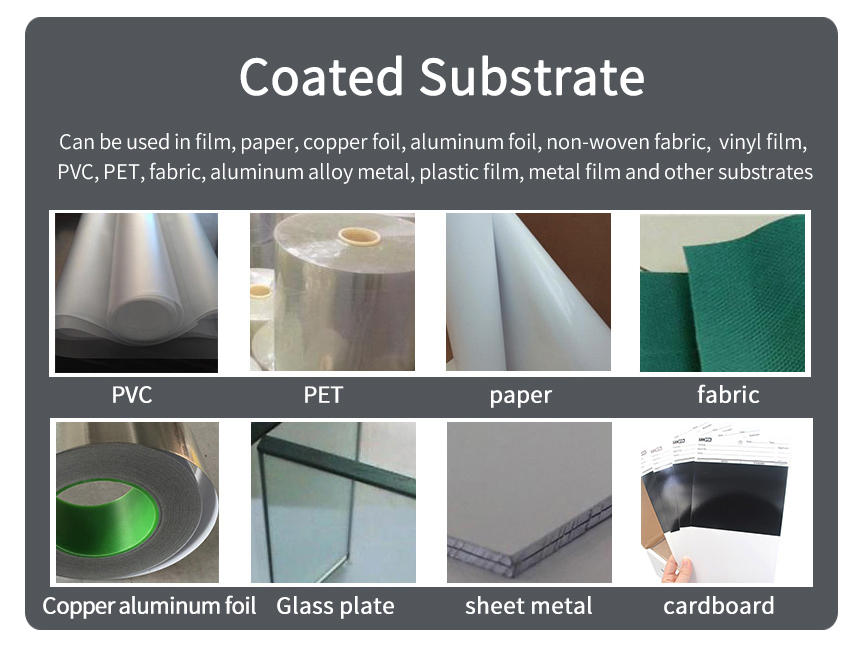

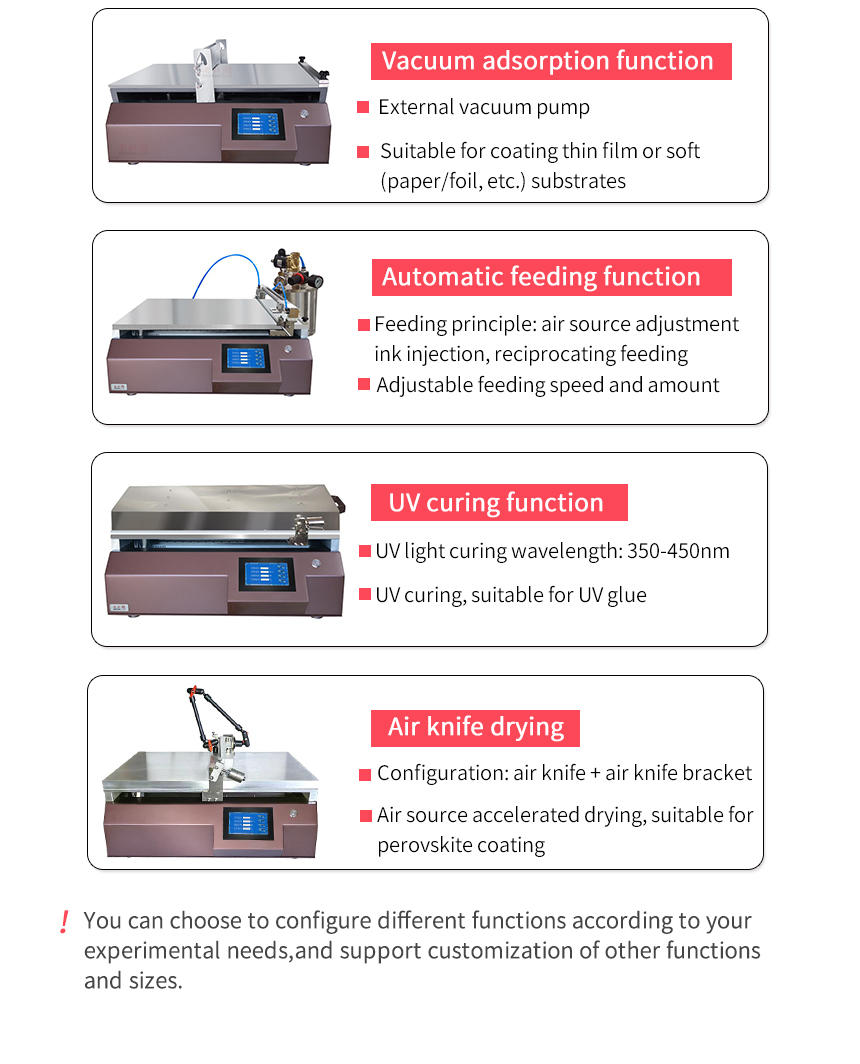

Drawdown Bar & blade heating + wind knife + wind knife bracket, suitable for perovskite Moulding proofing; Smoothness aluminum alloy baseplate, film size is 300 * 400mm, heating temperature up to 180 ℃.

zy

zy-

China Vacuum chuck drawdown Bar & blade Automatic Film Applicator TBJ-X3-XB with imported bar

$ 4176.00 -

HuiNuo TM1000Pro/500g Automatic Film Applicator bar Coater High Accuracy film applicator

$ 2250.00 -

HuiNuo TM3200/07 drawdown Bar & Blade vacuum adsorption Coater 50 * 70cm

$ 6387.00 -

HuiNuo TM2000Pro/06 Automatic Film Applicator drawdown blade Coater width 60 * 30cm customized model

$ 4808.00 -

HUINUO TM3300/03 metering rod & drawdown blade heating vacuum adsorption Film Applicator Standard 3 wire rods

$ 5124.00

Optional

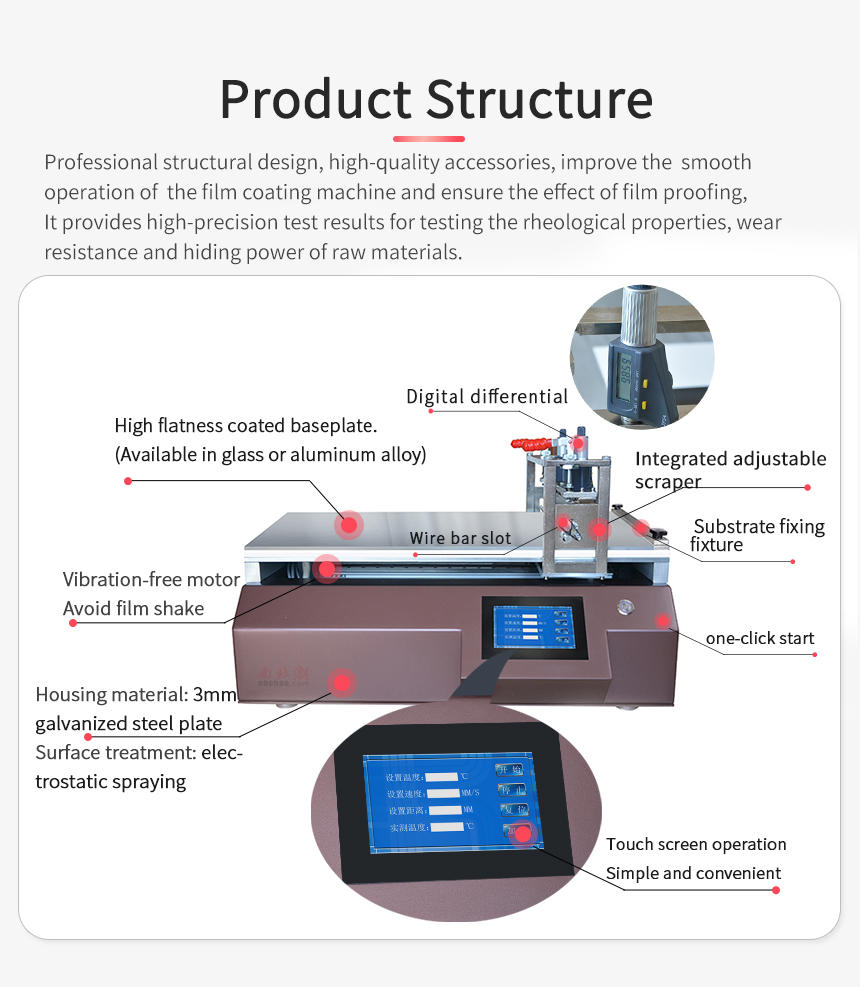

zy TBJ-B4-ABO Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Drawdown blade Accuracy | ±0.003mm |

| Drawdown blade Film thickness range | 0.2~ 10Mm drawdown blade can be lifted |

| Coating speed | 2~180mm/s |

| Coating size | 300*400mm |

| Mayer Rod Accuracy | ±0.001mm |

| Spreader Stick Specifications | 1-571.5 μm (Spreader Film thickness according to bar type) |

| Heating temperature range | RT+~180℃ |

| Drawdown blade length | 400mm |

| Host Power Supply | 220V 50Hz 1700W |

| Dimensions | 626*410*520mm |

| Temperature Uniformity | ±3℃ |

| Weight | Net Weight 65KG |

| speed control | Infinitely variable speed |

| Coating table material | aluminum alloy |

| optional accessories | Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, Silicone pad and Weight (for applications with uneven film thickness of Spreader substrate), film width control baffle |

| customizable function | Jet system device, UV solid inclusion device, automatic inking system |

| Mayer Rod Accuracy | ±0.001mm |

| Air knife gap | 0.05mm |

| Air knife Accuracy | ±0.002mm |

| Coating method | Bar + drawdown blade + air knife |

zy TBJ-B4-ABO Automatic Film Applicator Packing list

Film Applicator X1, Imported bar X1, Drawdown blade X1, Air knife x1, Air knife bracket x1, Product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Application of SWIRL/spin Film Applicator in the preparation of metal halide perovskite composite films

- Advantages of drawdown blade method in preparation of perovskite solar cells

- Application of Coating Machine in Perovskite Coating

- Comparison and Difference Between Offset Press and Film Applicator

- Preparation process of perovskite thin films

- Comparative analysis of coater rod type and doctor blade type

- Bar & casting knife heating Film Applicator Application of Water Treatment Film on Non-woven Fabric

- Perovskite Spreader Technology: Preparative Efficient Solar Cell Thin Film

- Application and Advantages of Coater in Antipyretic Sticker prepative

- Perovskite solar cell preparatory method using solvent immersion resistant applicator

TBJ-B4-ABO

TBJ-B4-ABO

TBJ-X3-ABO3

TBJ-X3-ABO3

TBJ-X4-ABO3

TBJ-X4-ABO3

TBJ-X3-ABO2

TBJ-X3-ABO2

TBJ-X3-ABO

TBJ-X3-ABO