Oven coil composite Coater with unwinding + scraping + drying + covering + winding function

With unwinding, scraping, drying, overlaying, winding functions, high-precision servo motor, with slot-die Spreader device, application width 300mm, compound speed 1-10m/min.

Factory

Factory-

Miniature Coil Coating Tester, Heating Coil Applicator TBJ-JTH-DJ1 Automatic Winding and Unwinding

$ 10333.00 -

Pharmaceutical Patch Coater Rxg-01/300uvcx pro Spreader cutting Coater

$ 23752.00 -

Oven coil composite coating machine Rxfay-01/400 tape unwinding + slot-die/gravure printing + drying + coating + winding function

$ 39539.00 -

UV UV curing coil coating machine Rxg-01/600uv automatic film laminating machine

$ 20595.00 -

Factory direct sales Rgdjy-02/350dcpro immersion coil Automatic Film Applicator wet film thickness 0.005-3mm Continuous experimental Automatic Film Applicator

$ 28488.00

Introduction

The oven coil composite coating machine is suitable for coating non-elastic materials such as paper, film, aluminum foil, plastic, non-woven fabrics, etc. It has the functions of unwinding, scraping, drying, laminating, and rewinding. It is an automatic composite coating machine for oven coils, using slit coating.

product structure

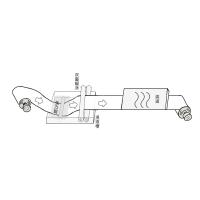

The oven coil composite coating machine is a multi-functional composite equipment with the functions of unwinding, scraping, drying, laminating and rewinding. The following is an introduction to the main structure of the device:

Unwinding device: The unwinding device is located at the starting end of the equipment and is used to place the substrate reel to be compounded. It usually includes components such as reel supports, tensioning devices and rollers to ensure stable conveying and tensioning of the substrate.

Blade coating system: The blade coating system is a key component in the coating process. It uses slit coating technology to evenly coat molten polyethylene plastic on the surface of the substrate. The system includes a coating roller, a coating tank, a blade and a roller, etc., which can achieve precise coating control.

Drying system: The drying system is located after the doctor blade coating system and is used to solidify the polyethylene plastic coated on the surface of the substrate to improve the quality and stability of the composite film. Drying systems usually use electric heating or hot air circulation, and the temperature and drying time can be adjusted as needed.

Composite device: The composite device is a key component that combines the coating on the surface of the substrate with another layer of substrate. It usually includes composite rubber rollers, pressure rollers and heating devices to ensure the firmness and uniformity of the composite film. The heating temperature of the composite rubber roller can reach 200°C to ensure good adhesion of the composite film.

Rewinding device: The rewinding device is located at the end of the equipment and is used to collect the completed film rolls. It usually includes components such as a winding device, a tensioning device and a winding reel, which can achieve stable collection and tensioning of film rolls and facilitate subsequent packaging and transportation.

Factory NBC-DJ7-300 Oven Slot-die Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating method | Slot-die Spreader |

| compound velocity | 1-10M/min (slow compounding speed, servo control, adjustable above 0.1m/min) |

| WFT | 0.005-3mm |

| Device size | Approx. Length 1800X Width 800X Height 1600mm |

| maximum discharge | 300mm |

| Maximum charge | 300mm |

| Coating size | Max.300mm |

| Drying Temperature range | Room temperature -200 ℃ |

| Drying tunnel length | 1m |

| Drying Power | 1KW |

| Power | 220V/2.5KW |

| Composite rubber roller | Heating temperature: room temperature~ 200 ℃ |

| Composite Accuracy | 0.5mm |

| motor | Servo motor |

Factory NBC-DJ7-300 Oven Slot-die Film Applicator Packing list

Machine x1, Manual x1, Encasement List x1, Certificate of Conformity x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle, application and selection of Electric Oven

- Principle and method of mold positioning for slit coating

- Adhesive Application Case of Coil Coater and Spreader Technology Introduction

- Technical Principle, Application and Selection of PT Film Roll-to-Roll Film Applicator

- Application of Slot die coaters in Lithium Battery Coating

- Selection method and maintenance technology of waterproofing membrane coater

- Technical Research and Practice of Application Case of Coil Coater in Butyl Rubber Spreader

- Epoxy coil coater technology and selection method

- Comparison and Difference Between Offset Press and Film Applicator

- Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

NBC-DJ7-300

NBC-DJ7-300