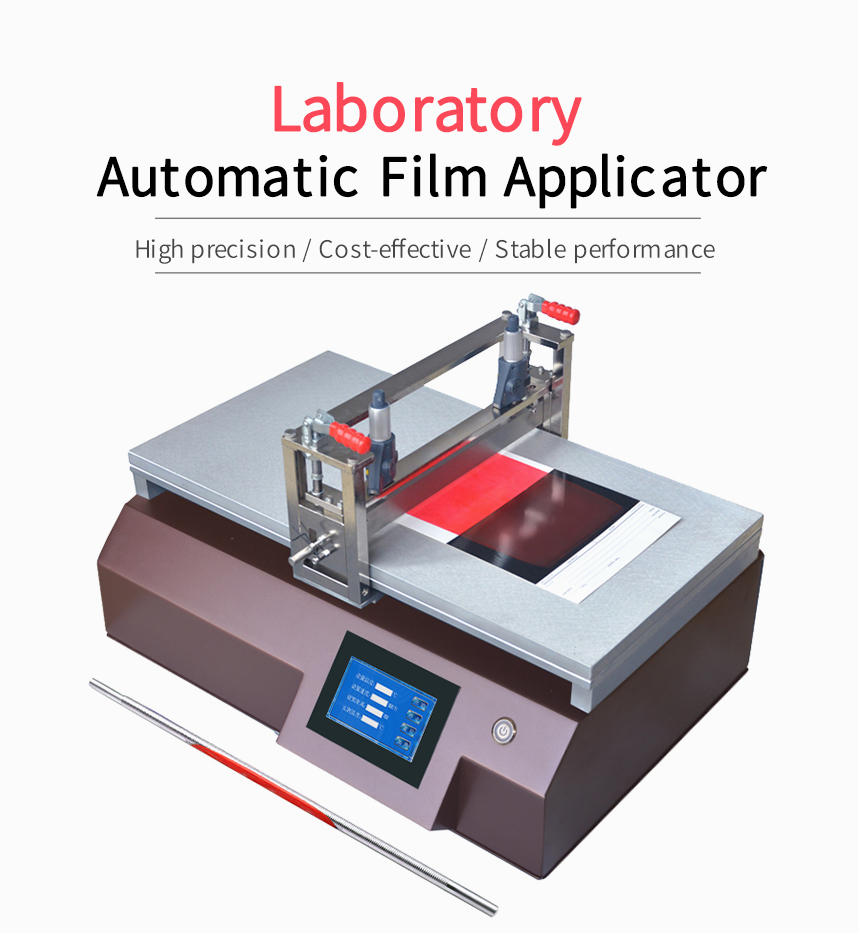

China TBJ-X1-DJ7UV UV curing Drawdown blade Film Applicator Vacuum chuck Coater

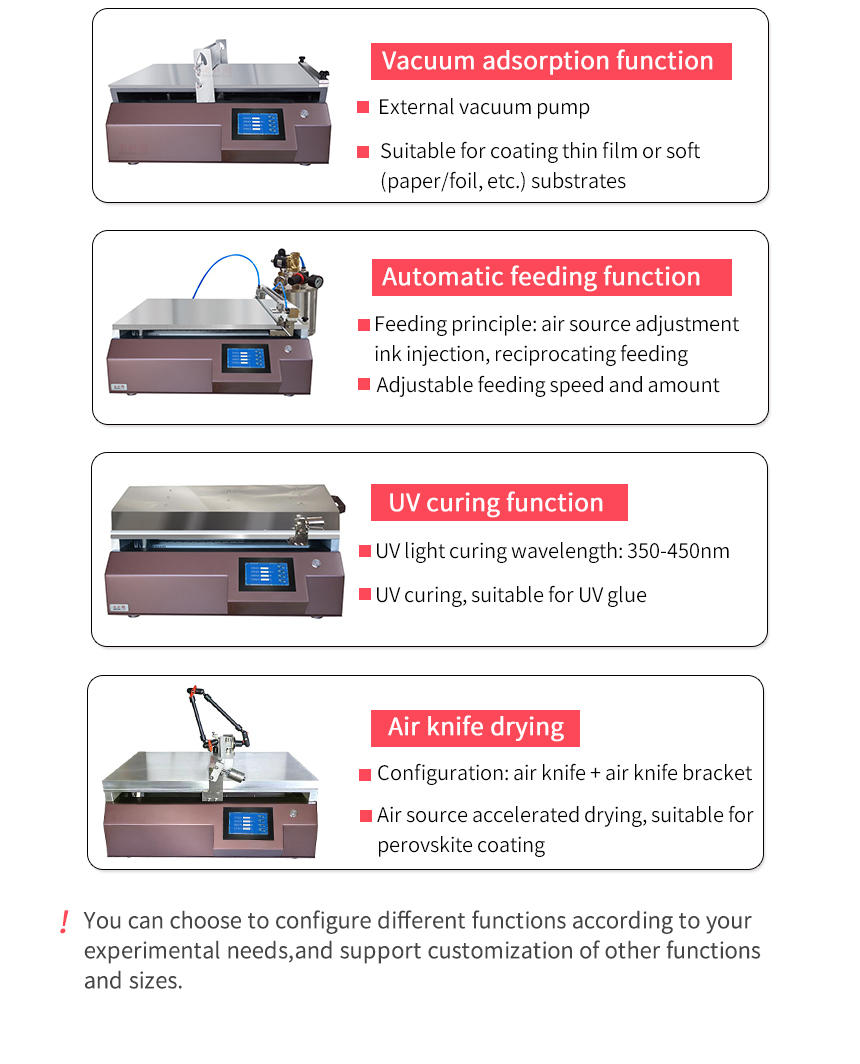

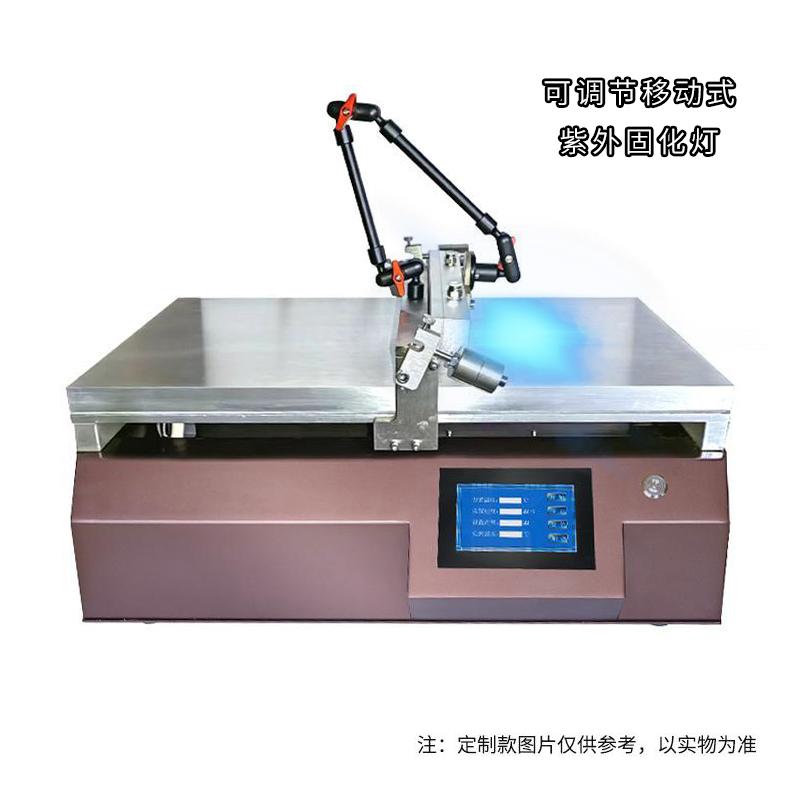

Vacuum chuck + Drawdown blade + Adjustable mobile UV ultraviolet curing lamp, UV Lamp is fixed on the Drawdown blade through the bracket and can be scraped while UV curing, the effective application width is 300mm, 800w UV Lamp.

zy

zy-

China TBJ-X3-DJ8 Automatic lame plating Vacuum chuck Film Applicator lame plating machine

$ 7649.00 -

China TBJ-X2-DJ1 Automatic Film Applicator Vacuum chuck drawdown Bar & blade Small Lab Film Applicator

$ 6229.00 -

China TBJ-B2-DJ6 Floor drawdown Bar & blade Coater Coating size 600 * 800mm

$ 7649.00 -

HuiNuo TM3300Pro/19 drawdown Bar & Blade heating vacuum adsorption Coater ECA 45 * 35cm

$ 6071.00 -

China TBJ-X3-DJ14 Multifunctional Automatic Feeding Film Applicator Drawdown blade Heated

$ 7649.00

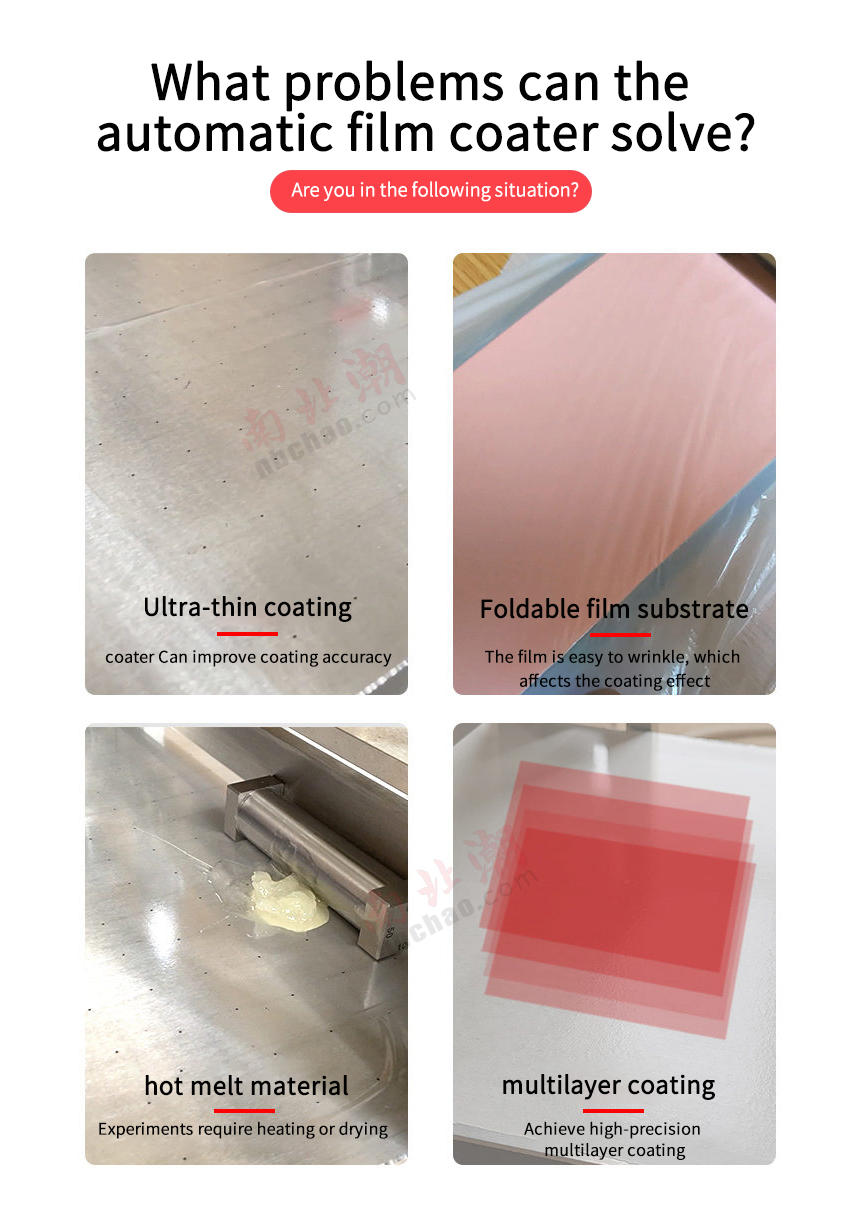

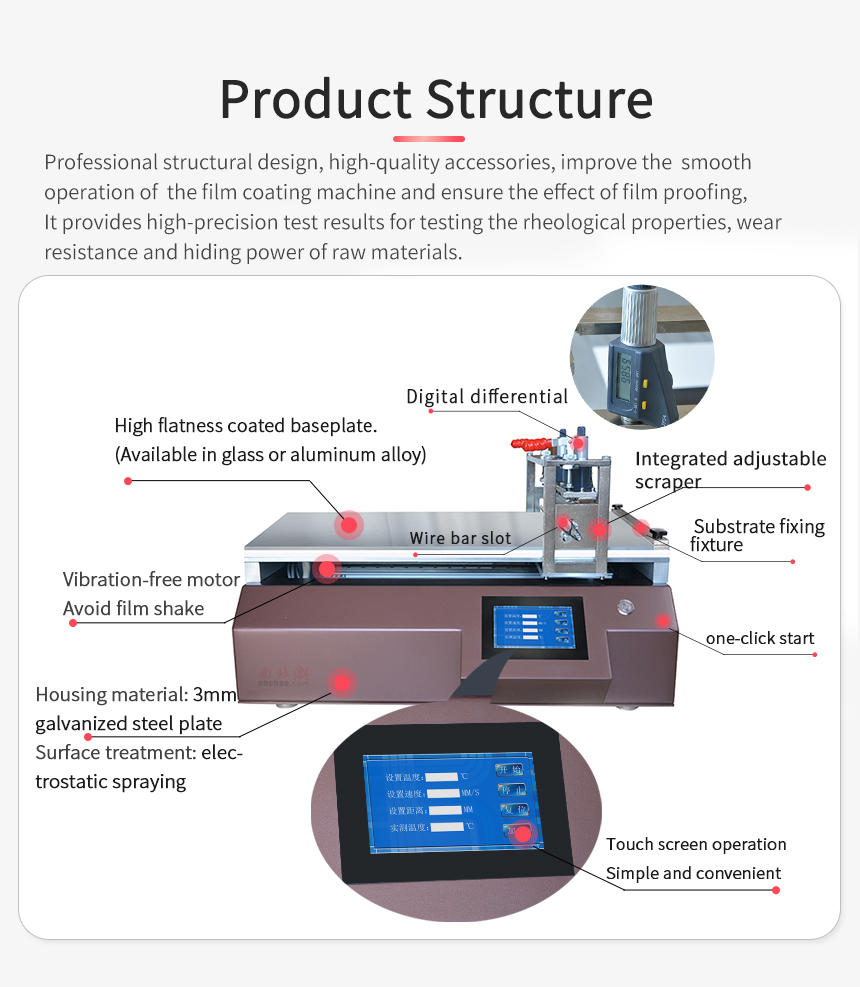

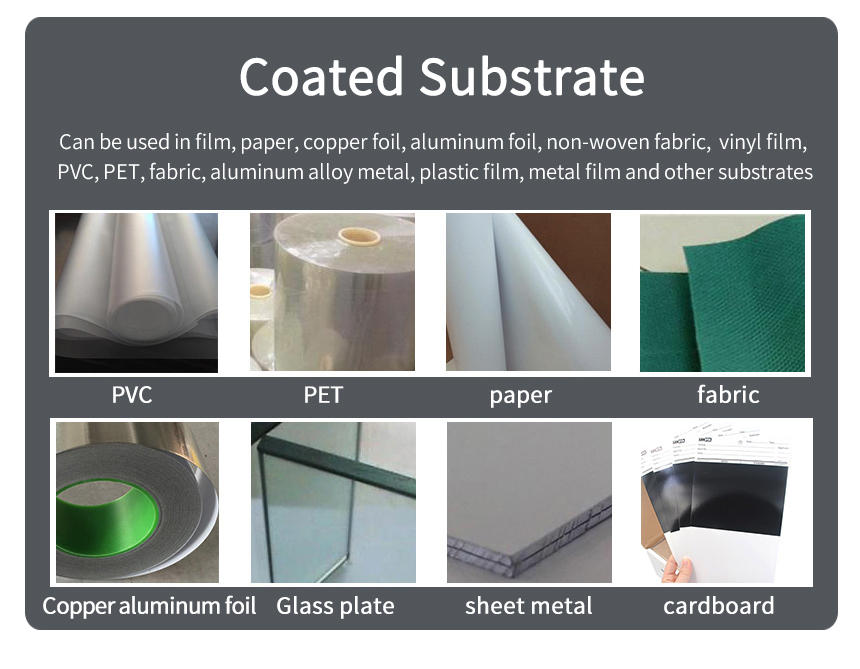

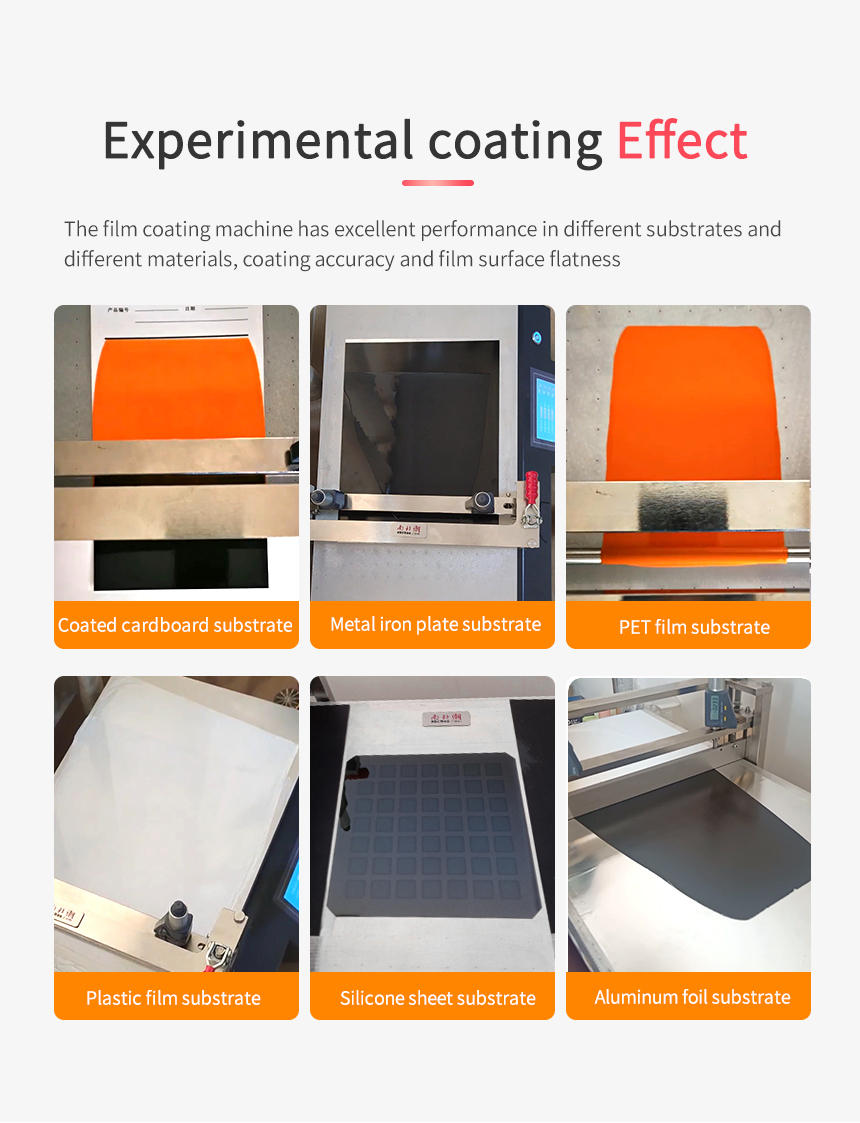

TBJ-X small coating testing machine for inspection all use imported accessories, and the price is cheap, has been favored by many multinational enterprise R&D institutions, many familiar universities and scientific research institutions at home and abroad. By controlling the speed and stable pressure to ensure the coating and gluing effect, and ensure the uniformity and stability of the coating and gluing.

TBJ-X1-DJ7UV ultraviolet curing automatic coating machine is a scraper type coating machine with vacuum adsorption, using a power of 800w ultraviolet lamp, the ultraviolet lamp is fixed on the scraper through the bracket, and the coating film is cured by ultraviolet light at the same time as the scraping of the scraper, which is suitable for UV glue, light-curing liquid and other coating films.

Optional

zy TBJ-X1-DJ7UV Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating Method | Drawdown blade + UV curing |

| Drawdown blade type | Drawdown blade |

| Drawdown blade material | 304 stainless steel |

| Drawdown blade Spreader Accuracy | ±0.003mm |

| Drawdown blade Coating thickness range | 0~ 10Mm adjustable |

| Coating Speed | 5~ 200Mm/s (< 5mm/s can be customized) |

| Effective coating Area | 400 * 300Mm (can be customized) |

| Spreader Itinerary | Digital arbitrary setting within the range of 1~ 400mm |

| Vacuum Area | 400 * 300Mm (can be customized) |

| Vacuum aperture diameter | Φ1.2mm |

| Vacuum hole pitch | 20*20mm |

| Vacuum pump size | 380*180*280mm |

| Host power supply | 220V 50Hz |

| Dimension | 630*410*520mm |

| speed control | Infinitely variable speed |

| Coating table material | aluminum alloy |

| UV curing area | 400*300mm |

| UV light main peak wave | 365nm |

| UV Light Power | 800W |

| UV light curing wavelength | 350~450nm |

| UV UV Lamp Spacing | 18*18mm |

| Substrate clamping method | Vacuum chuck |

| Control mode | Touch screen control |

| Optional Accessories | Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

| customizable function | Automatic lame plating device, automatic inking system, air knife drying, remote control, upper infrared heating, double extrusion Spreader |

zy TBJ-X1-DJ7UV Automatic Film Applicator Packing list

Film Applicator X1, External vacuum pump (oil pump) X1, Drawdown blade X1, UV light curing device x1 set, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Coating prepative handmade experts - Lab drawdown blade Film Applicator

- Ultrasonic Film thickness measurement by UV curing Coating on rigid wooden boards

- Why is the curing speed of UV curing Printing ink so fast? How to ensure a reasonable speed?

- Application of laboratory coater in LED fluorescent film Spreader

- Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- How to cure UV ink?

- Preparation and performance of high Gloss UV curing waterborne white topcoat

- Experimental Application and performance Test of Automatic Film Applicator for RTV Silicone Glue on Aluminum Panel

- Features of UV Curing Coatings

TBJ-X1-DJ7UV

TBJ-X1-DJ7UV