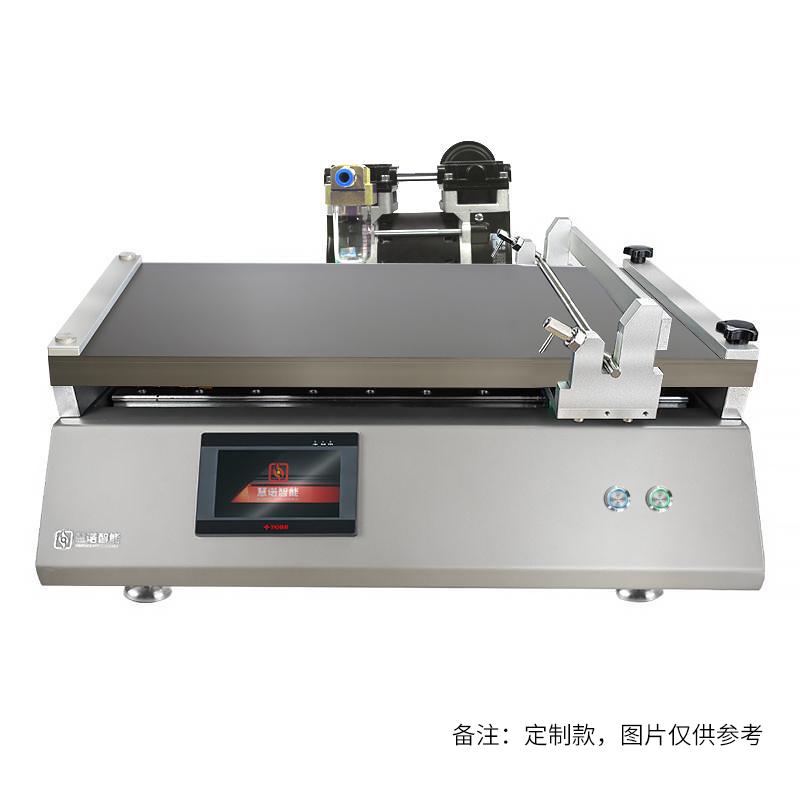

HuiNuo TM 2300/02 drawdown blade heating vacuum adsorption Automatic Scraping Machine Electric scraping equipment

Adjustable drawdown blade + heating + vacuum adsorption function, clamshell drawdown blade design, simple and fast cleaning, drawdown blade accuracy +/- 0.003mm, heating table is made of micro-porous ceramic material, Heating Temperature range RT +~ 180 ℃.

HuiNuo

HuiNuo-

CHINA TBJ-X2-DJ19 Cabinet smart multifunctional Film Applicator Coating size 600 * 1000mm

$ 47432.00 -

TM1300pro High-precision Laboratory Wire Bar Coater with Heated Vacuum Table

$ 4018.00 -

China TBJ-X3-DJ23 Experimental Automatic Film Applicator with Automatic Feeding System

$ 8281.00 -

China Bar Coater TBJ-A1-DJ4 Draw-Down Applicator customized film area 450 * 500mm

$ 2440.00 -

China Vacuum chuck Coater TBJ-GDO-JKXB drawdown Bar & blade Film Applicator

$ 2677.00

Overview

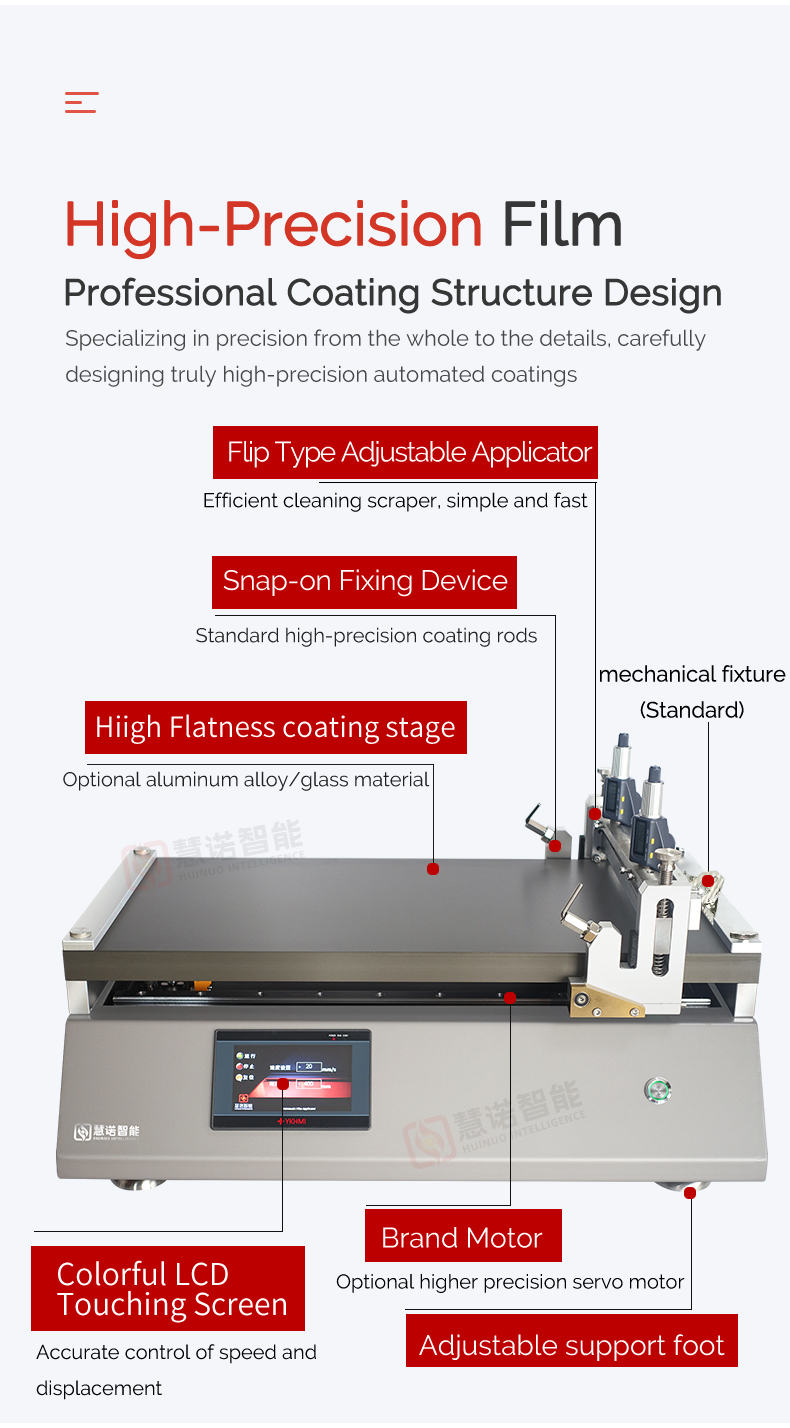

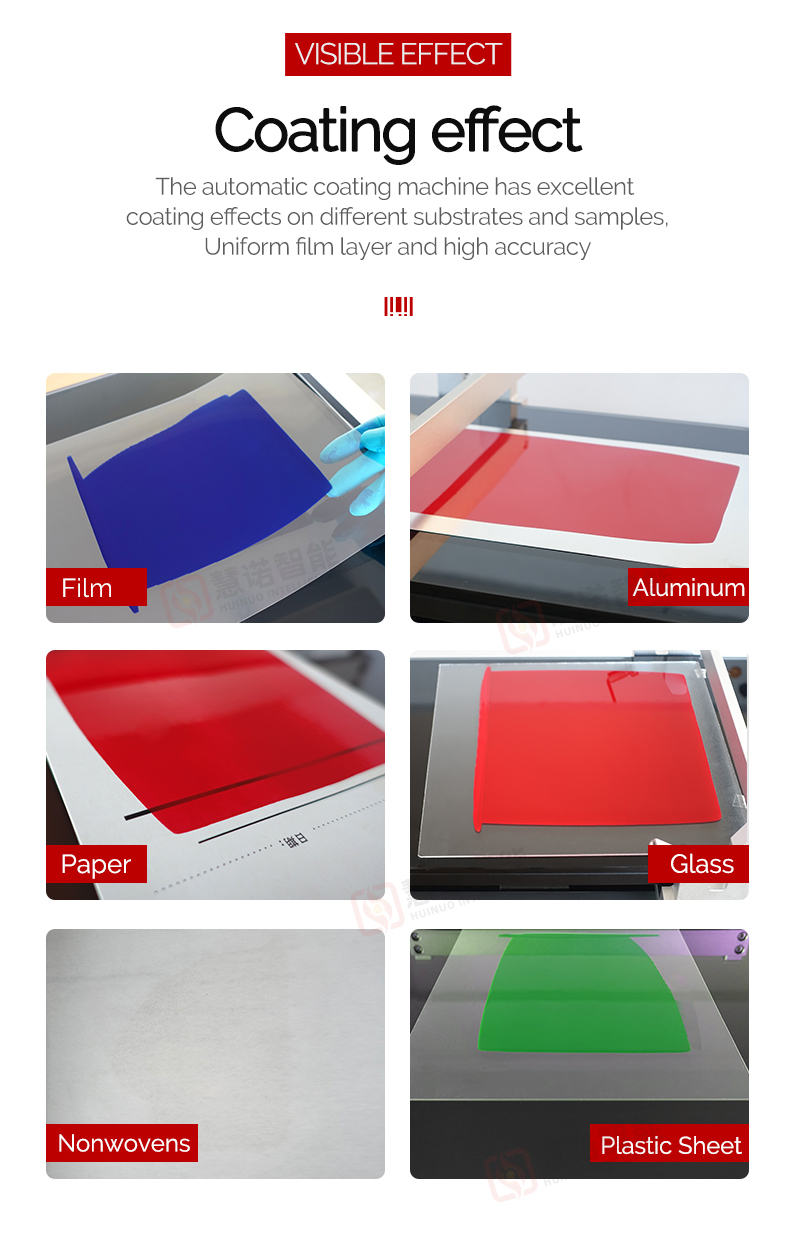

The automatic film coating machine is a device used to coat the film in the laboratory, replacing the manual coating film, and the coating film is carried out automatically, so as to improve the accuracy and efficiency of the coating film. The working principle of the experimental automatic film coater is to evenly coat the sample on the substrate by controlling the coating head and coating parameters to form the desired film.

This film coating machine is a scraper-type automatic coating machine, with heating and vacuum adsorption functions, the new type of wire rod installation method and clamshell scraper head greatly improve the coating efficiency, easy to clean, support speed control and coating length adjustment, suitable for high-precision automatic coating in the laboratory, in the university research institute, new materials, lithium battery, glue, resin and other laboratories for film proofing.

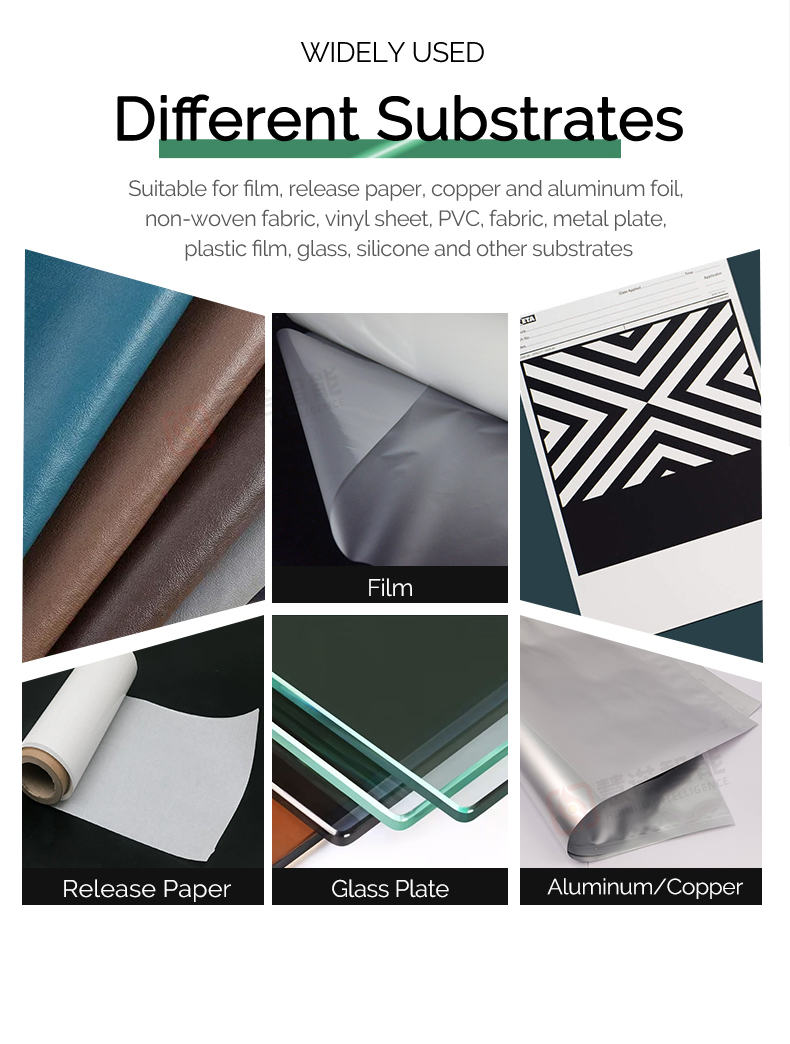

Application

The film coating machine is suitable for coating and sample preparation of coatings, inks, paints, slurries, lithium batteries, pressure-sensitive adhesives, resins, glues, polymer materials, chemicals, etc., and can be scraped on films, release liners, aluminum foils, copper foils, and tissue paper.

Features

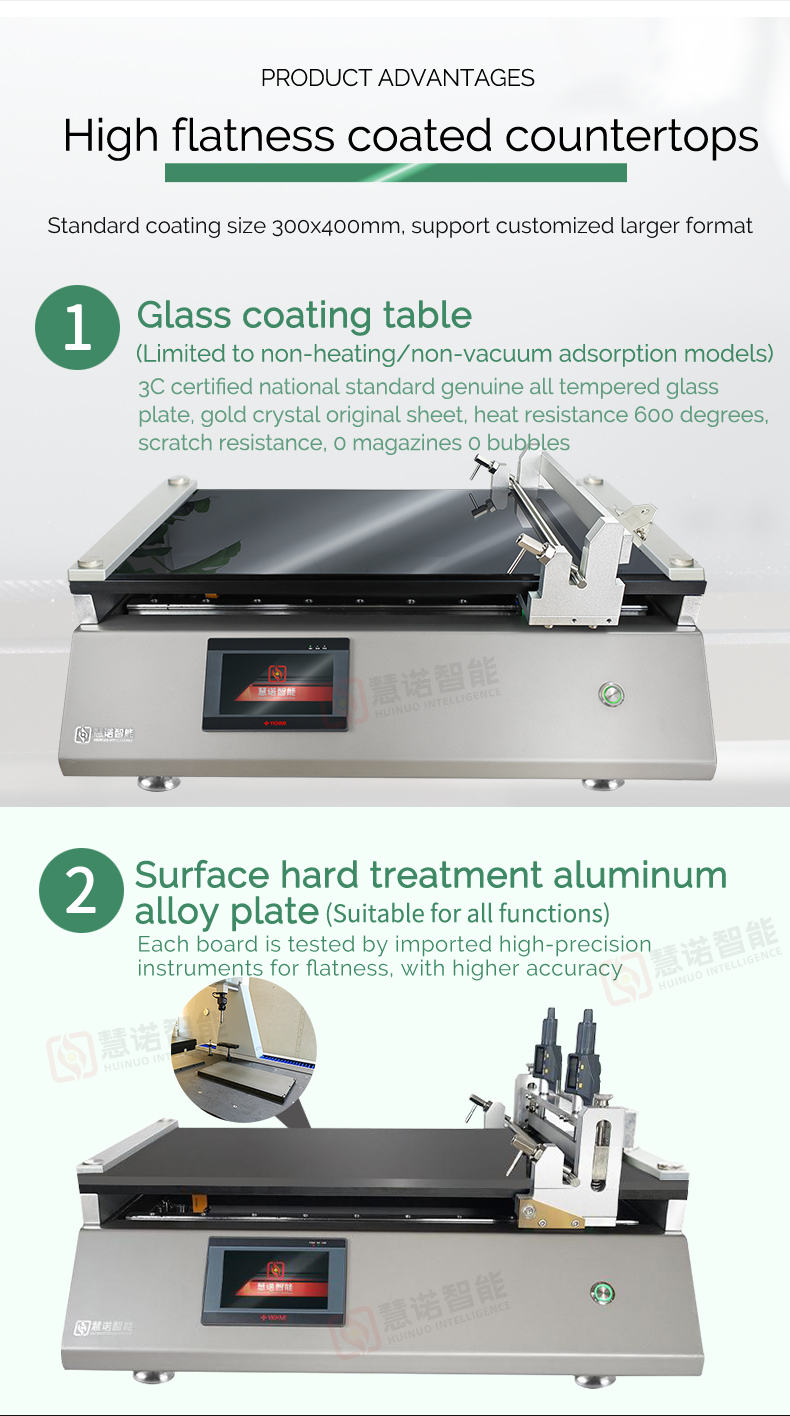

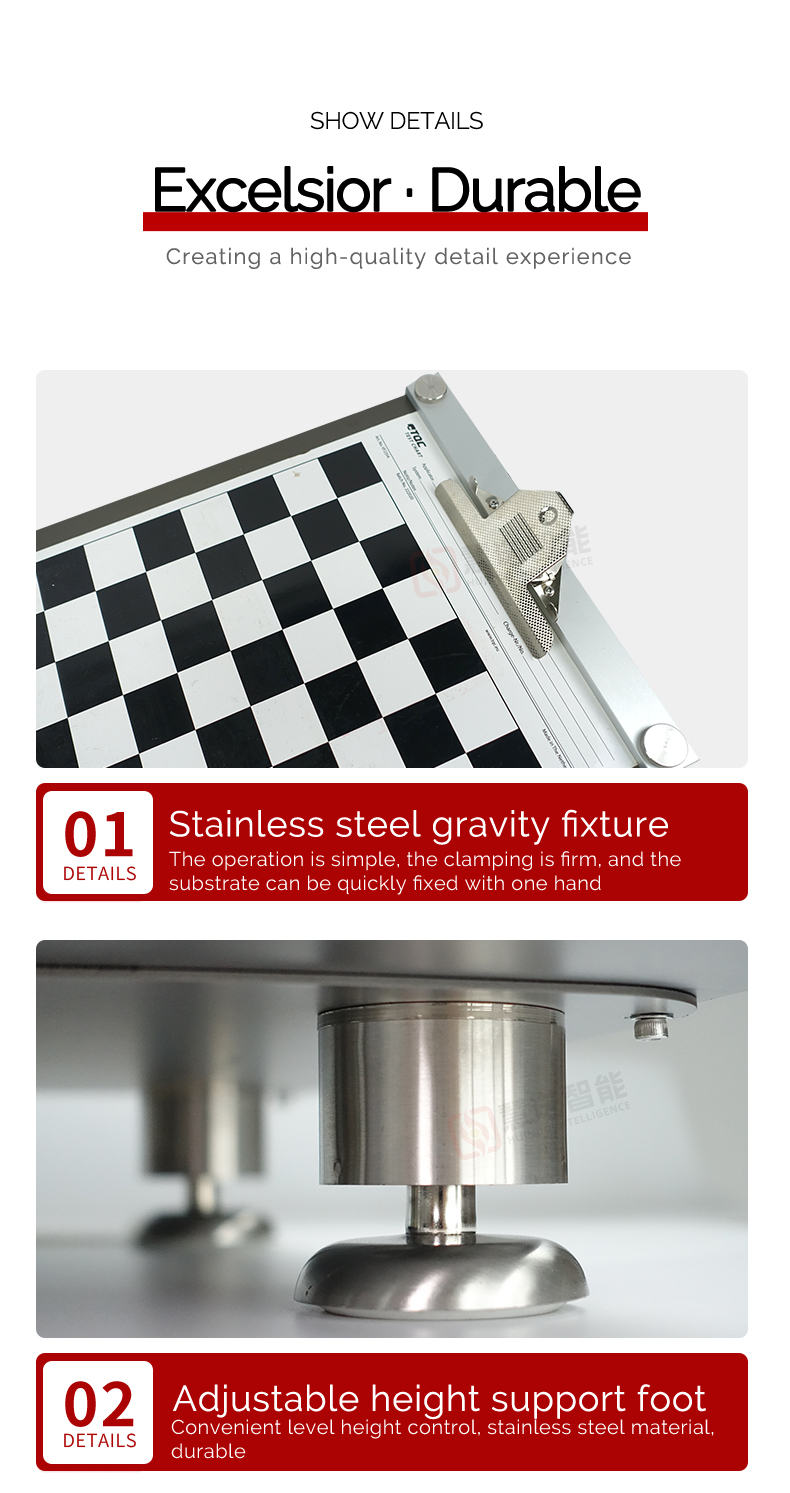

1) The surface is hard treated aluminum alloy table, with high hardness and wear-resistant, and the flatness of the table is tested by imported high-precision instruments.

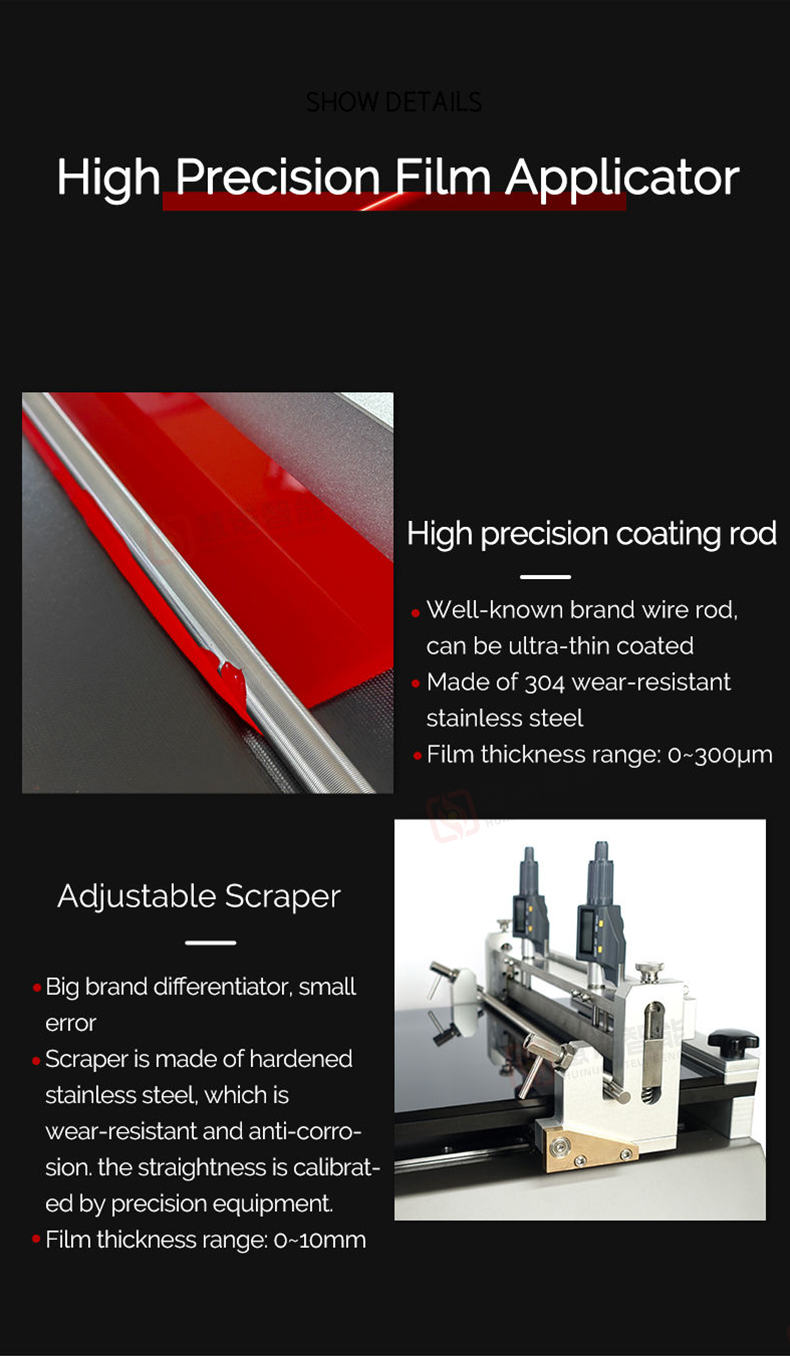

2) Big brand differential regulator, high film thickness control accuracy

3) With heating and vacuum adsorption function

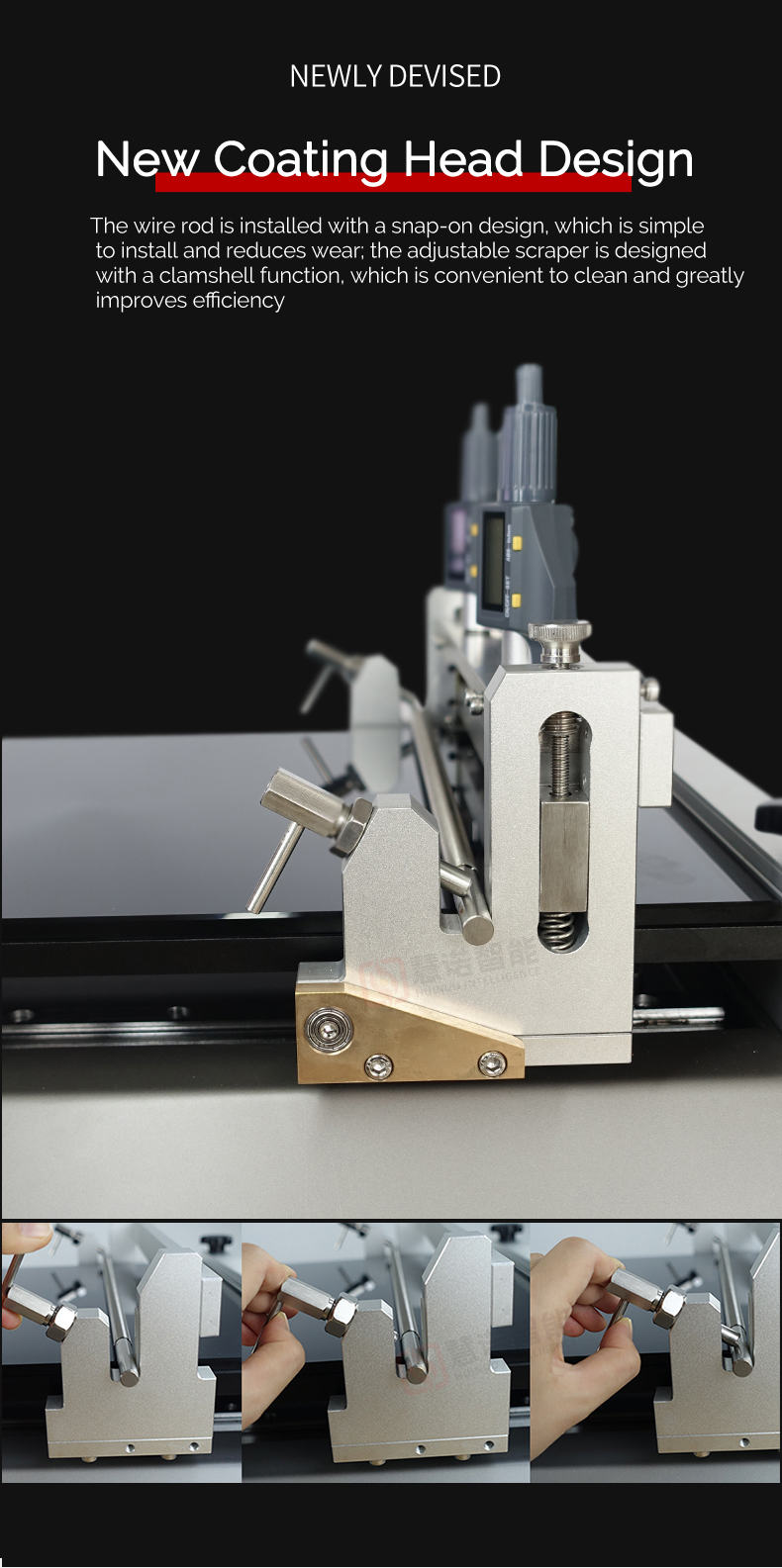

4) Clamshell scraper design, quick and easy to clean

5) Touch screen control panel, easy to operate

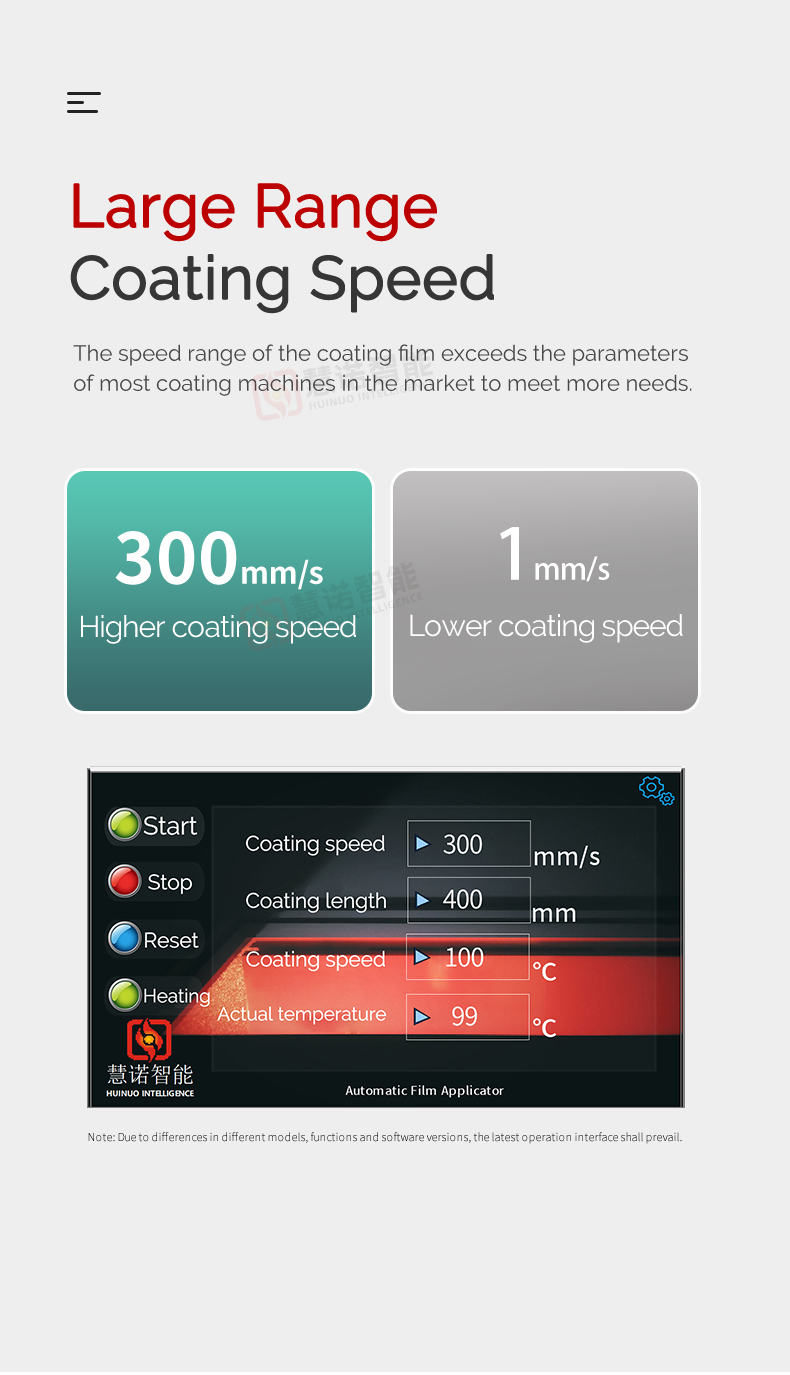

6) The coating length and coating speed can be adjusted freely

HuiNuo TM2300/02 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating method | Drawdown blade |

| Coating speed | 1~ 300Mm/s stepless speed regulation (can be customized) |

| Substrate clamping method | Vacuum adsorption + fixture |

| Coating table material | Microporous ceramics |

| Coating table size | 400*300mm |

| Effective coating Area | 300 * 200Mm (can be customized) |

| Drawdown blade thickness range | 0~10Mm (clamshell design is easy to clean) |

| Drawdown blade material | Die steel |

| Drawdown blade application width | 300mm |

| Drawdown blade Accuracy | ±0.003mm |

| Drawdown blade resolution | 0.001mm |

| Vacuum Area | 300 * 200Mm (can be customized) |

| vacuum aperture | Φ0.8mm |

| Vacuum hole spacing | 20*20mm |

| Pumping Speed | 5.4m3/h |

| Ultimate Vacuum | 50KPa |

| Vacuum Pump Power | 180W |

| Vacuum pump Weight | 7.1kg |

| Heating mode | Mica sheet heating (optional graphene heating, faster thermal conductivity) |

| Heating Temperature range | RT +~ 180 ℃ (higher temperature can be customized) |

| Temperature Uniformity | ±1℃ |

| Operating language | Chinese (can be customized in English) |

| Dimension | 658*438*400mm |

| Display | Color LCD touch screen |

| Host Power Supply | 100V~220V/50~60HZ |

| Power | 1800w |

HuiNuo TM2300/02 Automatic Film Applicator Packing list

Machine x1, casting knife x1, vacuum pump x1, manual x1, certificate x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

TM2300/02

TM2300/02