CHINA immersion coil drying air-cooled slitting machine Rdc-01/500cs dipping coating machine

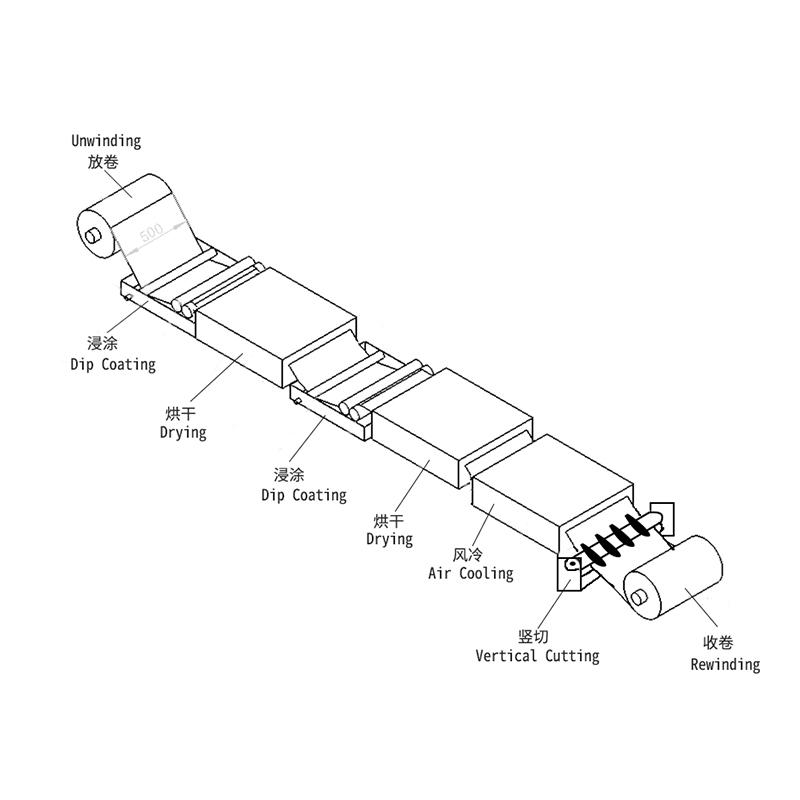

Dip coating, unwinding → first dip coating → drying → second dip coating → drying → air-cooled → vertical cutting → winding, effective application width 500mm, special for melamine dipped paper experiment.

Factory

Factory-

NBC-ZYTJ300 special Coater Spreader compound slitting integration

$ 19016.00 -

Coil drawdown blade Automatic Film Applicator Rxg-01/400 tape unwinding + scraping + drying + winding function

$ 14280.00 -

CHINA immersion coil drying air-cooled slitting machine Rdc-01/500cs dipping coating machine

$ 34803.00 -

Taigang TG-RR300 laboratory roll-to-roll small Coater small hot-melt adhesive Coater

$ 6071.00 -

Oven coil composite Coater with unwinding + scraping + drying + overlaying + winding function

$ 34803.00

This machine is mainly suitable for the process of melamine dipped paper.

Equipment process

Unwinding → first dip coating → drying → second dip coating → drying → air cooling → vertical cutting → winding (effective coating width 500mm)

Main part configuration

(1) Unwinding unit (1 group in total)

Structural features:

Type: single station

Effective unwinding width: 500mm

Effective unwinding diameter: ≤ φ 400mm

Put the reel: 3 " (0019 76mm) 1 piece of inflatable shaft (suspended structure)

Unwinding tension control: tension automatic control, magnetic powder brake, tension controller

Specifications:

Unroll main configuration:

Magnetic powder brake:

Tension controller:

Inflatable shaft: 3 "/cantilever type (winding part)

Factory Rdc-01/500cs Soaking coil drying air-cooled slitting machineSpecifications

| LIST | VALUE |

|---|---|

| main substrate | Plain base paper or printing decorative paper |

| glue | Mixture of melamine formaldehyde Resin and urea formaldehyde Resin |

| Spreader moisture | Adjustable (formed) according to the process |

| Coating method | soak |

| Coating size | Max.500mm |

| substrate | Less than 500mm |

| Roll surface width | 500mm |

| mechanical speed | 1.2M/min (0.1~ 1m/min production speed, depending on the process) The speed can be adjusted slowly |

| unwinding diameter | ≤ φ 400mm (paper core 3 ") |

| winding diameter | ≤ 500mm (paper core 3 ") |

| Heating drying method | External infrared heating, centrifugal fan hot air circulation |

| temperature control | 50~150 ℃ +/- 3 ℃ (maximum 160 ℃ in the intermediate temperature zone) |

| Curl the edges neatly | ±3.0mm |

| Total Installed Power | About 40kW (Power required for electric heating is about 35kW) |

| Equipment external Dimensions | (L x W x H) According to process changes and final design drawings |

| Teflon roller | 4 pieces (installed in front of the Spreader head respectively) |

| Power Supply | Three-phase five-wire 380V 50Hz |

| Unwinding Unit - Type | Single station |

| Unwind Unit - Effective Unwind Width | 500mm |

| Unwinding Unit - Effective Unwinding Diameter | ≤Φ400mm |

| Unwinding Unit - Unwinding Scroll | 3 " (φ 76mm) 1 piece of inflatable shaft (suspended structure) |

| Unwinding Unit - Unwinding Tension Control | Tension automatic control, magnetic particle brake, tension Controller |

| Front Traction Unit - Steel Roller | Φ42x500mm |

| Front Traction Unit - Motor | SEND/0.75KW (servo control) |

| Chilling down device | air-cooled |

| Cutting device | 3 air knives, you can freely control the cutting spacing |

Factory Rdc-01/500cs Soaking coil drying air-cooled slitting machine Packing list

Host x1, water bath dip coating module x2, drying module x2, air-cooled module x1, slitting device x1, rewinding device x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- List of experimental testing instruments for research and development of nano-composite water-based barrier coatings

- Some theory you need to know about the dip coating process

- What are the requirements for preparing test samples for aqueous dip paint?

- Dip coating process and dip coating machine

- This article takes you into the technical field of immersion coil coater

- What is leveling? What parameters affect leveling?

- Advantages and disadvantages of dip coating process and ideal use

- Operation Flow of Polymer Electrodeposition

- Diversity and applicability of Coating painting methods

- How to troubleshoot dip coating defects?

Rdc-01/500cs

Rdc-01/500cs