KAIRDA NDT271 Ultrasonic hardness gauge display

Support user material calibration function, can display Vickers and selected standard Hardness value at the same time, store up to 600 sets of data, equipped with 3.5 inch IPS LCD screen, continuous Working time more than 10 hours.

KairDa

KairDa-

Leeb Hardness Tester AMITTARI AL-150A split Leeb Hardness Tester

$ 369.00 -

Leeb Hardness Tester KAIRDA NDT290 Portable Richter Hardness Tester with printer

Login -

LANDTEK Leeb Hardness Tester shaped support ring (set)

$ 233.00 -

Portable Leeb Hardness Tester KAIRDA NDT230 Plastic Housing Richter Hardness Test Meter

Login -

KAIRDA NDT271 Ultrasonic hardness gauge display

$ 1553.00

Product Introduction

This ultrasonic hardness Tester is an innovative design based on the in-depth research on the principle of ultrasonic hardness measurement. The "User Materials" function has been developed to realize the needs of users for special materials or new material testing! It greatly expands the scope of use of ultrasonic hardness Testers.

Features:

The design is based on the standard: GB/T 34205-2017 "Hardness test of metal materials - Ultrasonic contact impedance method". It can perform high-precision inspection of a wide range of metal materials.

Two hardness scales are displayed to display both Vickers hardness and the hardness correspondence of other selected standards.

Dedicated circuit design supports hot-swappable probe operation.

The probe is plug-and-play, and the probe force value is automatically recognized.

Commonly used material hardness scales (HV, HB, HRA, HRB, HRC) are converted in parallel.

Includes three new material settings to facilitate hardness testing of special materials, and theoretically can test the hardness of all metal materials.

Built-in large-capacity lithium-ion rechargeable battery and charging control circuit; It can work continuously for no less than 10 hours; It has power-saving functions such as automatic sleep and automatic shutdown.

The display adopts a 3.5-inch IPS (In-Plane Switching) all-digital LCD display, which significantly improves color and response speed, and the content is vivid and rich, and the information is clear and intuitive.

With a wide Viewing Angle, even when viewed from the side, the colors and details of the picture are still clearly visible.

Chinese and English switchable display, user-friendly menu operation, simple and convenient.

The brightness of the LCD can be adjusted arbitrarily, which is convenient for use in gray and dim light environments.

USB communication interface, which can easily and quickly exchange data and set parameters with the PC.

A single main unit can be equipped with a variety of different probes to automatically identify the probe type in real time. No recalibration is required for replacement.

It can store up to 600 sets of hardness measurement data. Each set of data includes information such as measurement date, sensor type, material, number of times, single measurement, average, maximum, minimum, hardness system, etc.

The upper and lower limits of hardness values can be set in advance, and the automatic alarm is out of the range, which is convenient for users to need batch testing.

Metal housing, compact, portable, and highly reliable, suitable for harsh operating environments, resistant to vibration, shock and electromagnetic interference.

Powered by 3.7V lithium battery, support USB port charging.

There is an indicator icon on the LCD that shows the remaining battery power in real time; With charging process indication, the operator can always know the level of charge.

It has the function of calibration of the value display software.

Hardness measurement of special materials can be calibrated and tested using user materials

Main uses:

Installed mechanical or permanent assembled parts, mold cavities, heavy workpieces.

Failure analysis of pressure vessels, steam turbine generator sets and their equipment, and workpieces with very small test space.

Bearings and other parts, requiring formal original records of test results, material differentiation in metal material warehouses.

Rapid inspection of multiple measurement parts in a large area, small positions of the workpiece, such as gear roots, etc.

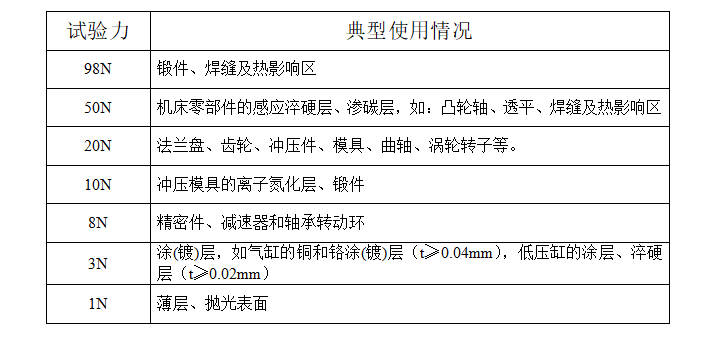

Typical Usage Scenarios

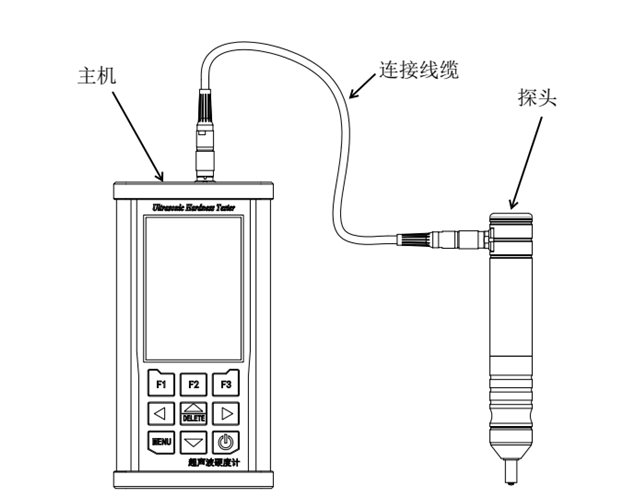

Product composition:

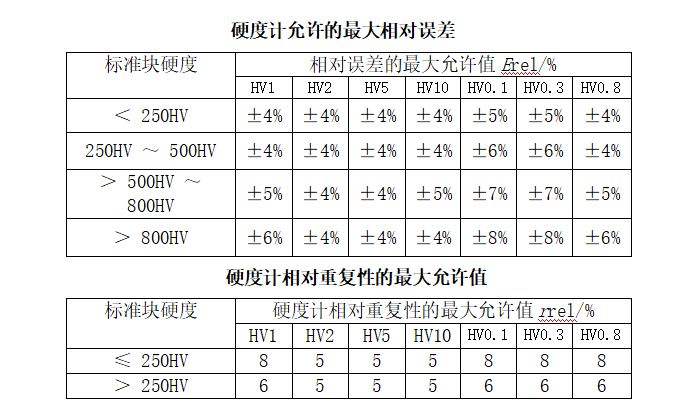

relative error and repeatability of the indicated values

KairDa NDT271 Ultrasonic hardness gaugeSpecifications

| LIST | VALUE |

|---|---|

| Measurement direction | Perpendicular to the surface of the workpiece under test |

| Hardness scale | Vickers (HV), Brinell (HB), Rockwell B (HRB), Rockwell C (HRC), Rockwell A (HRA) |

| Measurement range | HV:10~1999/ HB:76~618/ HRB:41~105/ HRC:20.3~68/HRA:60.7~85.6 |

| Measurement results show | Vickers (HV) + Hardness Ruler |

| Measurement material | Steel and cast steel, cast aluminum alloy, pure copper |

| user profile | 3 types, with setup wizard |

| show | 3.5 inch IPS full digital color LCD display, resolution 480 × 320 |

| probe identification | Automatic recognition/manual setting, support hot swap |

| Data storage | Maximum 600 groups (measurement times 1~ 32) |

| Operating Voltage | 3.7V lithium-ion battery pack |

| Working time | More than 10 hours |

| Charging Power Supply | 5V/1000mA |

| Communication interface | USB2.0 |

| Dimension | 159 × 83 × 39mm (host), φ 22 × 141mm (probe) |

| Weight | The host is about 370g, and the probe is about 210g. |

| Operating temperature | 0℃~+40℃ |

| Storage temperature | -20 ℃~ + 75 ℃, Relative Humidity ≤ 85% |

| Operating Conditions | The surrounding environment has no vibration, no strong magnetic field, no corrosion medium and serious dust |

KairDa NDT271 Ultrasonic hardness gauge Packing list

Host X1, probe X1, probe cable X1, standard Hardness block X1, communication charging cable X1, charger X1, instruction manual X1, certificate X1, warranty card X1, instrument case X1.

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- ActiveGB/T 44760-2024

- ActiveDL/T 1845-2018

- ActiveGB/T 13313-2008

- ActiveGB/T 17394.1-2014

- ActiveGB/T 17394.4-2014

- ActiveGB/T 17394.3-2022

- ActiveGB/T 17394.2-2022

- AbolishGB/T 17394-1998

NDT271

NDT271