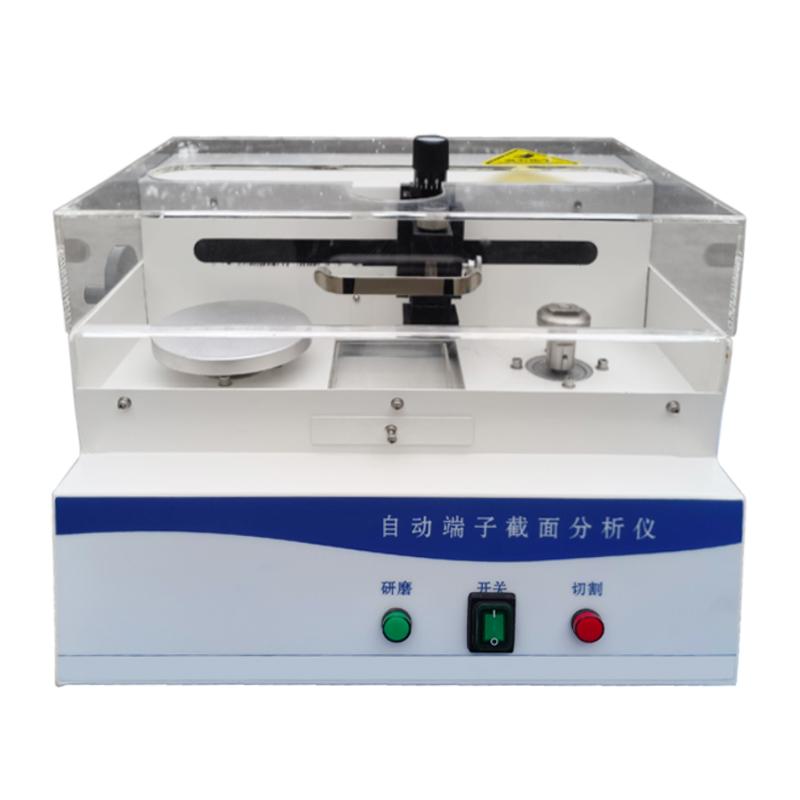

Chinese NBC-7052 Integrated Terminal Section Analyzer, Manual

Video Total Magnification 45X~ 512X, wire application range 0.01mm2~ 120mm2, imagery system: Japan SONY photosensitive module industrial high-resolution video system, grinding sandpaper 1200 #, standard fixture 0.01 - 120mm ², grinding equipment precision integrated semi-automatic cutting grinding equipment.

Factory

Factory-

YUZHOU PG-2DA metallographic sample polishing machine, double disc stepless speed regulation, cabinet structure

Login -

CHINA NBC-4327 leakage marking Tester high Voltage leakage marking testing device

$ 1204.00 -

Huicheng DSC-600S Differential Scanning Calorimeter FTC and STC Dual Mode 600 ℃

$ 5566.00 -

SuJie CLG-1000 Powder Sample Weighing Cabinet, Weighing Hood

$ 2956.00 -

PUSHEN PS 2461 wooden camera obscura with 2 15W fluorescent lamps

$ 274.00

Introduction

Integrated terminal section analyzer is a precision detection and analysis equipment specially developed for the quality inspection of the wire harness industry, the whole set of wire harness section analyzer system consists of terminal cutting and grinding integrated equipment, optical sampling imported from Japan, corrosion cleaning, section image acquisition system, wire harness terminal picture measurement and analysis system, using cutting and grinding integrated equipment, the most technical, cutting and grinding completed at one time, fully ensuring the flatness requirements of the terminal. The complete inspection system can complete the processing and analysis of a terminal within 3 minutes, which greatly improves the speed of terminal section quality inspection. The operation is simple, convenient and fast, using Japan high-definition image acquisition system, accurate measurement and analysis to escort your production.

How to use:

After the terminal is clamped by a special wire harness fixture, the terminal is cut and ground by the X-axis screw rod of the handwheel drive. The time required for terminal cutting, grinding and polishing is within 1~2 minutes. The internal structure is clearly reflected by cleaning and grinding the surface of the terminal by cleaning the chemical solution, and the newly developed special software for cross-section analysis is used to measure the terminal height, width, height-width ratio, terminal crimping area, wire harness crimping area, compression ratio, burr height, width, burr rate, distance between crimp wings, distance between the bottom, porosity and other items, and can instantly export the report and automatically judge whether all items are qualified. The measurement accuracy at the maximum magnification is 1 ~ 2μm.

Features

Independent speed control of cutting and grinding, and real-time cutting speed and grinding speed display. Large square harness and small square harness choose different rotation speeds for better cutting effect.

The use of tooth clamp, the surface of the special treatment corrosion resistance is very strong, different Wire diameters into different tooth positions to better support firmly.

Adopt Japan high-performance ultra-depth of field wide-angle high-definition optical system, magnification 45 times ~ 512 times. Extremely thin lines that exceed AWG38 can also be clearly expressed.

The pure high-resolution terminal cleaning solution of Sinopharm Analysis is used, and the terminal will not be blackened or hurt the body after cleaning, and the MSDS safe use certificate will be issued.

Factory NBC-7052 Integrated terminal section analyzer (manual)Specifications

| LIST | VALUE |

|---|---|

| Terminal section analysis | Optical inspection system of segmental zoom imported by Chuo Seiki |

| total video magnification | 45X~512X |

| Scope of application of wires | 0.01mm2~120mm2 |

| Power Supply | AC100V~AC240V |

| Imagery system | Japan SONY photosensitive module industrial high-resolution video system 5 million |

| Cutting blade specification | φ 105X0.5mm/φ 150X0.5mm (imported from Germany, delicate and durable cutting rear end surface is delicate) |

| abrasive sandpaper | 1200# |

| Standard fixture | 0.01—120mm² |

| Grinding equipment | Precision integrated semi-automatic cutting grinding equipment |

| Professional terminal section analysis software | With encryption lock and CD |

| High-precision datum | 0.01/10mm |

| Terminal corrosion | Liquid cleaning (5S complete) |

| Light source | All-white adjustable LED lighting device |

| Dimension | 500×350×350mm |

Factory NBC-7052 Integrated terminal section analyzer (manual) Packing list

Host X1, fixture X1, cutting abrasive wheels X 5, grinding sandpaper X 5, image reduction cleaning solution X1 (50ml), Microscope X1, computer X1, software X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

NBC-7052

NBC-7052

NBC-7053

NBC-7053