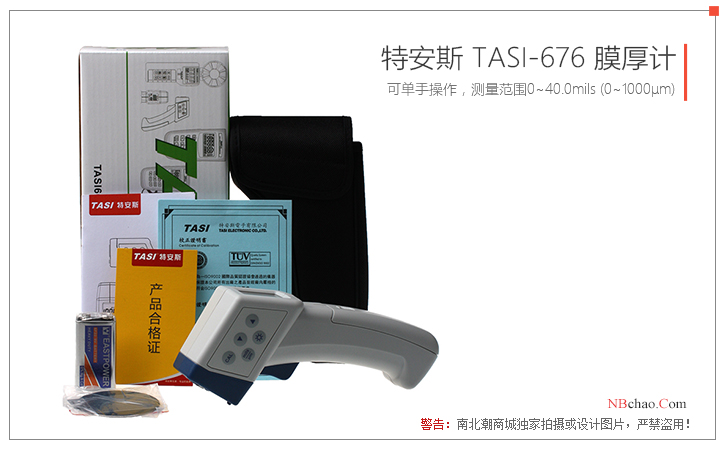

TASI TASI-676 film thickness meter Measurement range: 0~1000μm dual function type

The TASI-676 gun type film thickness meter is a dual-function digital display film thickness meter based on iron and non-iron. The thickness measurement range of TASI-676 is 0~1000 μm, and the resolution is 1 μm.

TASI

TASI-

PUSHEN PIG Multipurpose Dry-Film Detector

$ 640.00 -

LANDTEK CM8823 film thickness eddy Current Coating Thickness Gauge

$ 261.00 -

CHINA CTG-802-3000F Coating Thickness Gauge

$ 234.00 -

Defelsko N built-in detachable probe

$ 656.00 -

LANDTEK CM8825N Handheld Thickness Gauge Integrated Handheld Thickness Gauge

$ 313.00

Introduction

TASI-676 Gun Film Thickness Gauge is a handheld Film Thickness Gauge, magnetic and non-magnetic dual-function Film Thickness Gauge, which can detect both magnetic and non-magnetic metal substrates at the same time.The TASI-676 pistol Film Thickness Gauge has a built-in sensor that automatically recognizes different substrates for thickness measurement. The membrane Thickness Gauge is very ergonomically designed, the display is facing the surveyor, the buttons are designed in the hand part for easy one-handed operation, and the operation button is designed on the side of the Film Thickness Gauge for easy buttoning.

The TASI-676 Pistol Thickness Gauge not only has a display backlight reading function for reading the display reading in the dark, but also has an automatic reading lock function and an automatic shutdown function to extend battery life.

Live shot

Instructions

1. Make sure that the front end of the Film Thickness Gauge sensor is away from any substrate or magnetic field.

2. Press down the trigger until the screen is displayed, then release the trigger, and wait for the screen to display "um" or "mils" and HOLD before the measurement.

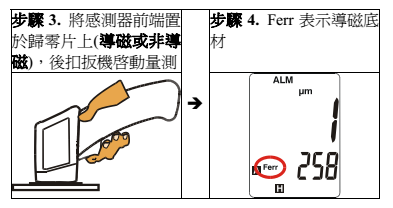

3.The front sensor of the TASI-676 pistol Film Thickness Gauge is partially attached to the object to be measured.

4. Gently pull the trigger and release it for measurement, and wait for the Film Thickness Gauge to display the reading.

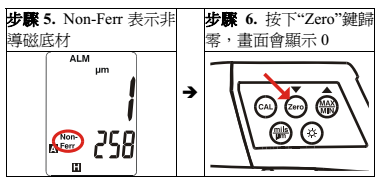

5. The type of substrate will be displayed with the reading value, and the magnetic conductive substrate will show "Ferr".The magnetic conductive substrate is shown "Non-Ferr".

6. When the thickness to be measured exceeds the range that can be measured by the Film Thickness Gauge, the screen display will remain the same as before. The buzzer will only beep once. If notWhen the substrate type is displayed and the reading value is displayed as "run", that is, when the boot screen is displayed, it representsThe type of substrate is not discerned by a Film Thickness Gauge.

7.Gun typeThe Film Thickness Gauge automatically records each data, and can use the "MAX/MIN" key to switch the maximum value, minimum value, maximum minimum value, average value and total number of transactions.

8. Automatic Power Off (APO): If there is no operation of the Film Thickness Gauge for 15 seconds, the power of the Film Thickness Gauge will be automatically turned off to prolong the battery life.

Precautions for use

1. Before using the Film Thickness Gauge, please read the operation safety instructions and user manual

2. Do not place the Film Thickness Gauge near any device that generates a strong magnetic field or electrostatic field, as this may cause the Film Thickness Gauge to malfunction.

3. Do not use the Film Thickness Gauge when exposed to corrosive or flammable gases. This could disrupt the aftermath or cause an explosion.

4. Do not use the Film Thickness Gauge in an environment that is directly exposed to sunlight or condensation, as this may cause the Film Thickness Gauge to deform or the insulating cup to be damaged, or cause the Film Thickness Gauge characteristics to exceed the specifications.

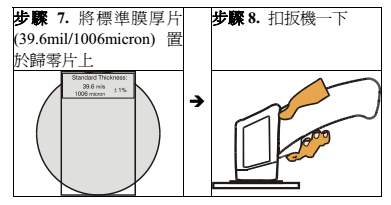

5. One point correction: This action needs to be performed every time you take a measurement

6. Two-point calibration: It is recommended to perform this action at common test points to increase the accuracy of measurement.

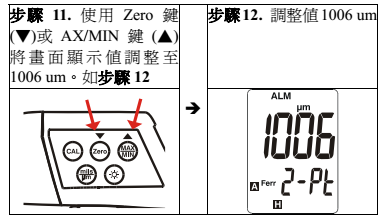

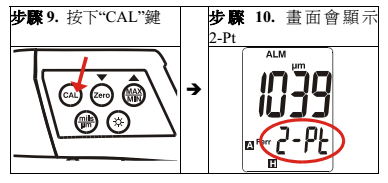

Two-point correction steps

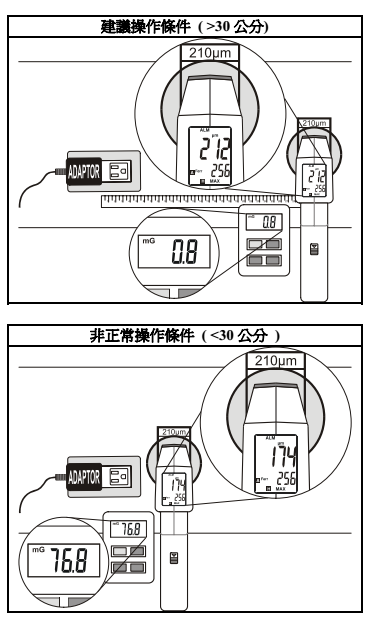

Schematic diagram of the proposed operating conditions

TASI TASI-676 Film thickness MeterSpecifications

| LIST | VALUE |

|---|---|

| Measurement principle | Magnetic Induction + eddy Current |

| Measurement range | 0~1000μm |

| margin of error | ±3% |

| Resolution | 1μm |

| probe | F and N integrated probe |

| statistical function | Measurement Times, MAX Maximum, MIN Minimum, Average |

| icon function | without |

| Power Supply | 1 * 9V alkaline battery |

| Calibrated Certificate | without |

| system language | Chinese |

| Display screen | 3 ½ digit LCD display, maximum 1999 readings |

| supporting software | without |

| Machine Weight | About 157g (including battery) |

| Machine size | 148*105*42mm |

| Response time | 1s |

| Voltage prompt | When the battery Voltage is lower than the operating Voltage ,"+ - " display |

| shutdown mode | automatic |

| Accuracy test environment | 23 ℃ +/- 5 ℃, Relative Humidity < 75% R.H. |

| Operating temperature | 0~50℃ |

| Storage temperature | -20~60℃,0~70%R.H. |

| Accessories | Manual, battery, leather case |

| Relative Humidity | <80%RH |

TASI TASI-676 Film thickness Meter Packing list

Host x1, manual x1, battery x1, leather case x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Study on common control technology of color coated steel film thickness

- Coating Film thickness measurement, see this is enough

- Film Film thickness determination method

- Preparation method of film

- Film Film thickness determination method

- Teans TASI676 Dual-purpose Thickness Gauge Operating Instructions

- The role of Thickness Gauge in steel pipe coating mass inspection

- What factors affect the accuracy of Film thickness measuring instrument?

- Talking about powder coated Film thickness measurement and paperless technology

- Coating construction performance testing Application instrument type summary

TASI-676

TASI-676