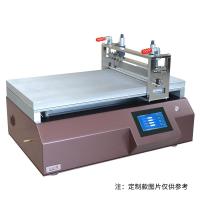

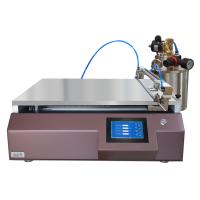

CHINA TBJ-X3-DJ24 automatic experimental Coater with automatic feeding system

Rod & Drawdown Blade heating vacuum adsorption four in one, with automatic feeding system, increase Spreader area 300 * 800mm, speed accuracy 1mm/s.

zy

zy-

HUINUO TM1000pro High-accuracy Wire-rod Film Coating Apparatus

$ 1966.00 -

China Fixture Film Applicator Accessories

$ 151.00 -

Huino TM3300Pro/45 Automatic Film Applicator metering rod & doctor blade Spreader Heating vacuum adsorption Effective Spreader area 100 * 60cm

$ 17437.00 -

CHINA TBJ-X1-DJ8 Detachable drawdown blade Vacuum adsorption Film Applicator ECA 500 * 600mm

$ 6387.00 -

Chinese TBJ-B1-DJ7 experimental drawdown blade Coater bracket height adjustable, ECA 400 * 400mm

$ 7176.00

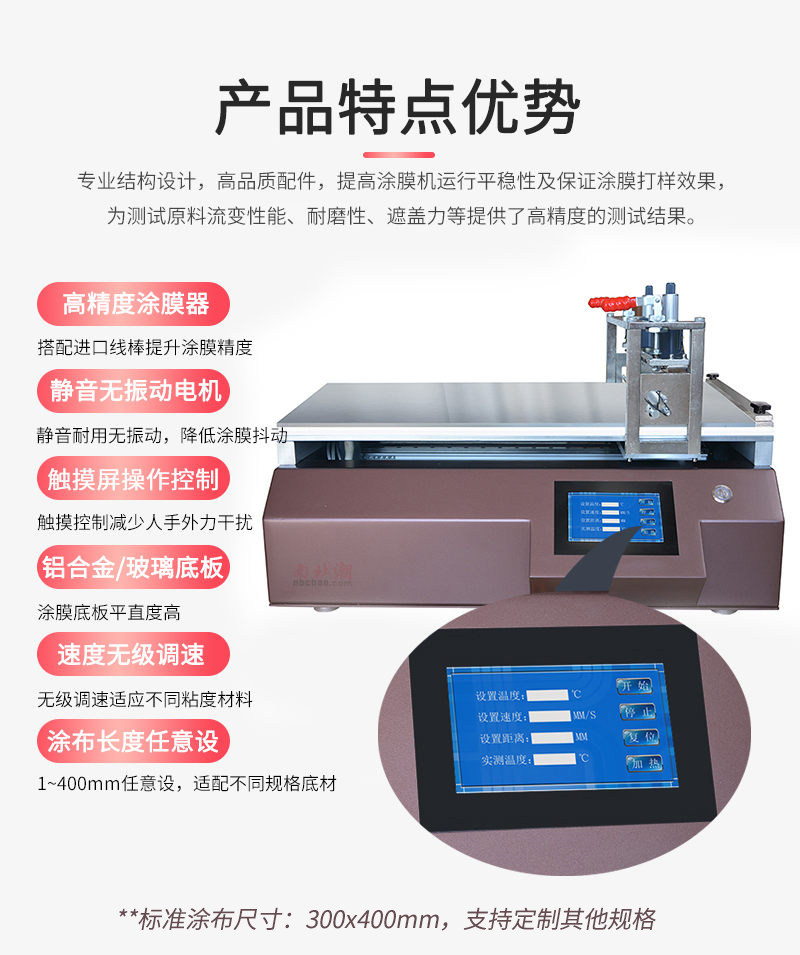

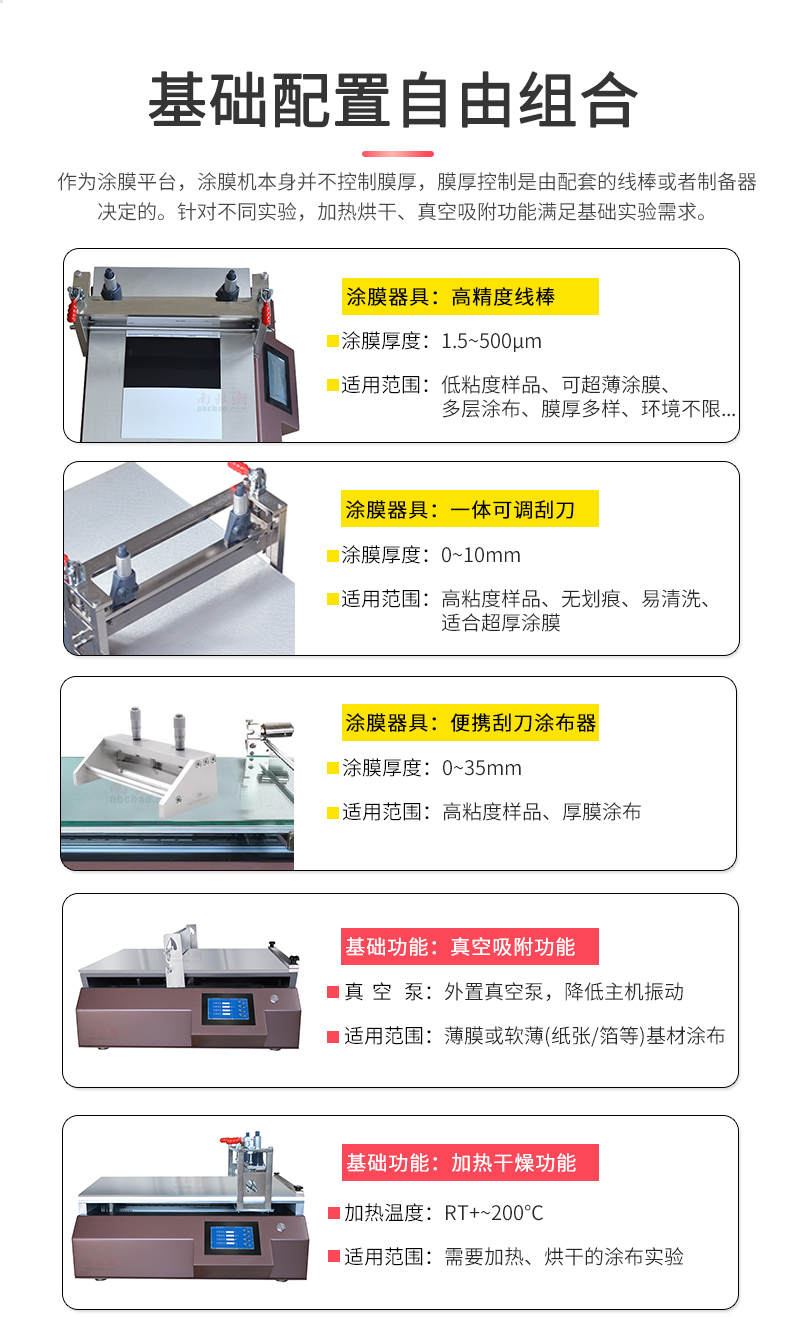

TBJ-X automatic experimental coating machine adopts imported accessories, the price is cheap, and it is favored by multinational enterprises, familiar universities and scientific research institutions. The equipment guarantees the effect of coating and gluing by controlling the speed and stable pressure, and ensures the uniformity and smoothness of the coating. TBJ-X3-DJ24 automatic coating machine is a four-in-one film coating machine with automatic feeding system, with heating and vacuum adsorption functions, using wire rod + adjustable doctor blade coating, effective coating format 300*800mm.

Manual coating can easily lead to uneven coating, which can vary more from person to person, affecting the test results between comparison samples. The fully automated experimental coater is designed to allow the operator to easily apply precise wet films on different substrates and improve the reproducibility of the coating film. The device is able to precisely control the coating speed and the pressure applied to the applicator, resulting in a uniform and reproducible coating, improving the accuracy and reliability of test results.

Optional

zy TBJ-X3-DJ24 Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Drawdown blade Accuracy | ±0.003mm |

| Drawdown blade thickness range | 0.001-10Mm adjustable |

| Coating speed | 5-200Mm/s (< 5mm/s can be customized) |

| Wire Rod Coating Thickness Range | 1-571.5 μm (Spreader thickness determined according to rod model) |

| vacuum aperture | Φ1.2mm |

| Vacuum hole spacing | 20*20mm |

| Vacuum pump size | 380*180*280mm |

| Spreader Accuracy | ±0.001mm |

| Host Power Supply | 220V 50Hz |

| speed control | Infinitely variable speed |

| Coating table material | aluminum alloy |

| Spreader Accuracy | 0.001mm |

| customizable function | Jet system device, UV solid inclusion device |

| Feeding principle | Air source pressure flows out |

| Feed Sport Mode | Reciprocating linear motion |

| Feeding back and forth traverse speed | 2-150mm/s |

| spit Volume | Adjustable (by adjusting the air pressure and the running speed of the discharge port) |

| Shaft transmission mode | Timer belt |

| Feeding system air source | 0.6Mpa, can be connected to the trachea of φ 8 (self-equipped) |

| Power Voltage of charging system | 220V,50Hz |

| Tank pressure | Maximum withstand 8Mpa |

| Material of feeding barrel | 304 stainless steel with a wall thickness of 4mm |

| Feeding bucket configuration | Safety valve, pressure regulating valve, pressure gauge, discharge valve |

| Optional Accessories | Leakage tank, substrate fixture, trimming horizontal height support foot device, Glass plate, silicone pad and Weight (for applications with uneven thickness of Spreader substrate), application width control baffle |

| Speed regulation Accuracy | 1mm/s |

| Temperature range | RT+~180℃ |

| Temperature Accuracy | ±3℃ |

| Feeding drum Volume | 1L |

| Heating mode | Baseplate heating |

zy TBJ-X3-DJ24 Automatic Film Applicator Packing list

Film Applicator X1, External vacuum pump X1, doctor blade X1, imported wire rod X1, automatic feeding system x1, product manual X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Principle, structure and application of hot-melt adhesive laboratory coater

- Explore the fundamental principles and technical analysis of laboratory coaters

- Tape laboratory coater technology and film accuracy optimization elements analysis

- Analysis and application of self-adhesive laboratory coater technology

- The preparatory application of laboratory coater in AR membrane

- Application and precautions of laboratory coater in preparation of solder paste

- Selection of laboratory coater in preparation of polyethersulfone membrane

- Application and Advantage Analysis of Polyetherimide Coated on Glass by Laboratory Coater

- Technical application of laboratory coater coating adhesive on PET film

- Application of laboratory coater coating aluminum oxide paste on PET film

TBJ-X3-DJ24

TBJ-X3-DJ24

TBJ-X3-DJ5

TBJ-X3-DJ5