Automatic Film Applicator for large coils unwinding + scraping + drying (8m oven) + heating film laminating + trimming + deviation correction + winding function

With unwinding - scraping - drying - heating film laminating - trimming - correction - winding function, drawdown blade, oven length 8 meters, application width 500mm, rubber roller heating temperature up to 200 ℃.

Factory

Factory-

CHINA immersion coil drying air-cooled slitting machine Rdc-02/500clcs dip coating machine

$ 39539.00 -

Huino JDH - 0.4/300 uvb lcl ak small multifunctional coil Coater comma scraper Spreader width ≤ 300mm

$ 17122.00 -

Oven coil automatic composite Coater with unwinding + scraping + drying + covering + winding function

$ 22173.00 -

Factory Direct Rdh2-03/500 immersion coil Coater double comma drawdown blade three temperature zone drying

$ 47432.00 -

CHINA NBC-6025FB pilot production hot-melt adhesive Coater film aluminum foil film equipment

Login

Introduction

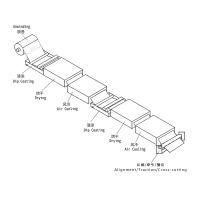

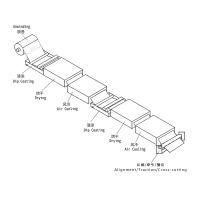

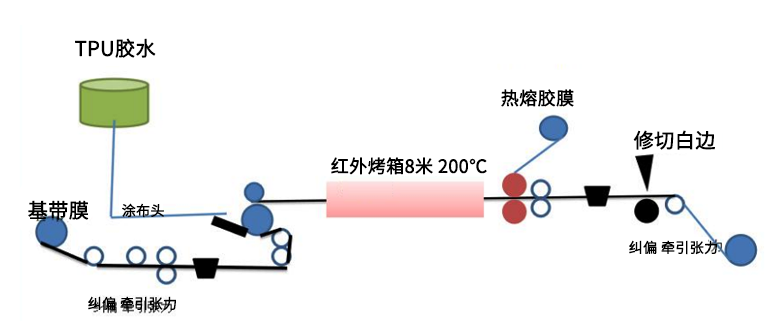

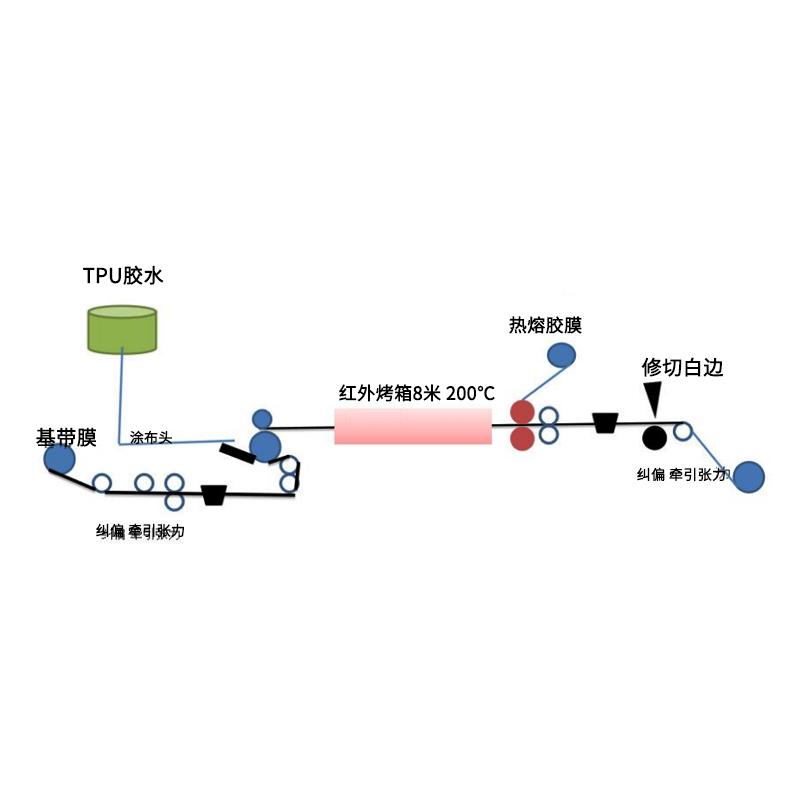

The coating program of RXG-08/500HRET large coil automatic coating machine is unwinding-scraping-drying-heating lamination-trimming-deviation correction-winding, equipped with 8-meter oven device, effective coating width of 500mm, rubber roller heating temperature of 200°C, suitable for hot melt adhesive coating film.

Structure diagram of the coating procedure

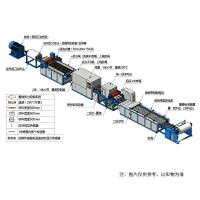

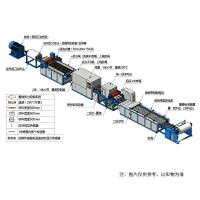

Factory Rxg-08/500hret Automatic Film ApplicatorSpecifications

| LIST | VALUE |

|---|---|

| Coating speed | 1~10m/min |

| application width | 100-500Mm adjustable |

| WFT | 0.005-3mm |

| maximum discharge | 500mm |

| maximum charge | 500mm |

| Effective application width | 500mm |

| Drying Temperature range | Room temperature -200 ℃ |

| Drying channel length | 8m |

| Drying Power | 1KW |

| Power/Power | 220V/2.5KW |

| rubber roller | Heating temperature: room temperature~ 200 ℃ |

| Spreader head | Drawdown blade |

| Coating size | Max.500mm |

Factory Rxg-08/500hret Automatic Film Applicator Packing list

Host x1, Manual x1, Encasement List x1, Certificate of Conformity x1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Analysis of extrusion hot-melt adhesive coater technology and comparative study of coil hot-melt adhesive coater

- Application and Technological Innovation of Coater Scratching Hot-melt Adhesive on PET Film

- Experimental Application of Automatic Film Applicator for Coating Hot-melt adhesive on Breathable Film

- Technical introduction of hot-melt adhesive coater

- Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

- Application of laboratory coater in EVA hot-melt adhesive

- Fiberglass hot-melt adhesive coater technical analysis and operation guide

- Explore the technical principle, type and Spreader of Bopp hot-melt adhesive coater

- Analysis and application of non-woven hot-melt adhesive coater technology

- Selection and Application of Laboratory Film Applicator in Wooden ground floor film laminating

Rxg-08/500hret

Rxg-08/500hret