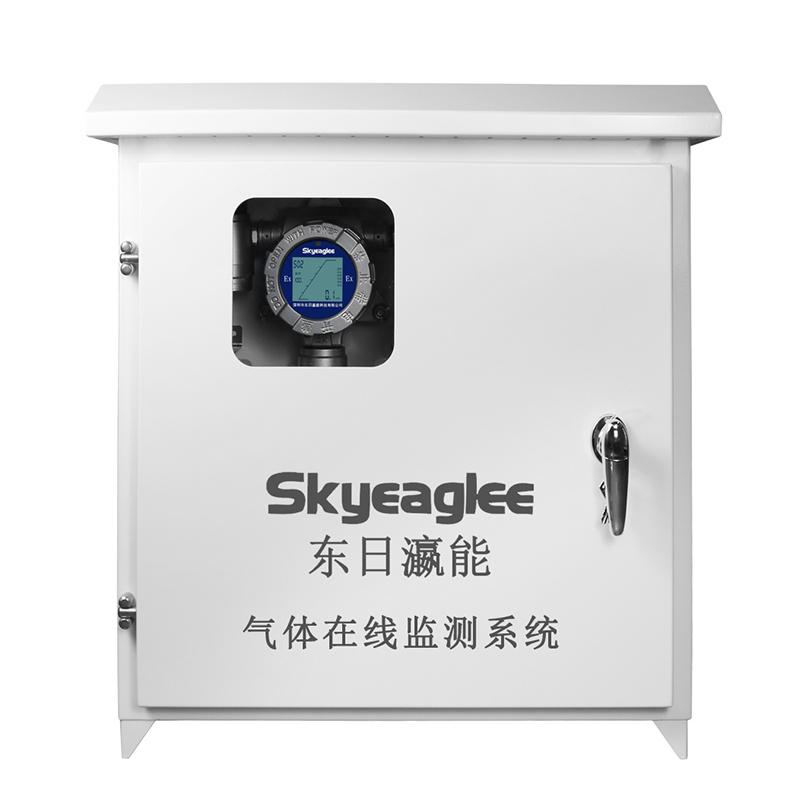

SKYEAGLEE SK-7500-LEL-JY LEL online monitoring system LEL concentration Detector

Non-explosion-proof model, detection range 0-100% LEL, detection accuracy +/- 3% F.S., with real-time data transmission, report statistics, graphic Data analysis and data export functions.

Skyeaglee

Skyeaglee-

GUOYUGRA GY/VGD-200-SiH2Cl2-G (0-10ppm) dichlorosilane Detector

$ 893.00 -

HUIRUIPU HRP-T1000-O2 Oxygen Gas Detector (No Display No Light)

$ 174.00 -

Empaer AATL-CH4 (4G) Pathfinder Series Fixed Methane Detector

$ 384.00 -

GUOYUGRA GY/VGD-200-C8H10-G Fixed Xylene Detector, infrared detection 0-1% Vol

$ 956.00 -

HONEYEAGLE HNAG1000-H2 Fixed Hydrogen Detector 0-50000PPM

$ 616.00

Introduction

SK-7500-LEL-JY LEL online monitoring system (hereinafter referred to as the monitoring system) continuously monitors the LEL content parameters of organic matter in the pipeline.

The data processing system of the monitoring system has the functions of real-time transmission of on-site data, report statistics, graphical data analysis and data export, etc., which realizes the unattended work site. The whole system has a simple structure, wide dynamic range, strong real-time, flexible networking, low operating cost, and the system adopts modular structure, easy to combine, and can fully meet the requirements of communication with the DCS system within the enterprise.

Enforce the standard

GB3836.1-2010 "Electrical equipment for explosive gas atmospheres Part I: General requirements"

GB3836.2-2010 "Electrical Equipment for Explosive Gas Atmospheres Part II: Flameproof Type "d"

GB 3836.15-2000 Electrical equipment for use in explosive atmospheres – Part 15: Electrical installation in hazardous locations (except coal mines)

GBT50493-2019 Design Standard for Detection and Alarm of Combustible Gas and Toxic Gas in Petrochemical Industry

GB12358-2006 General Technical Requirements for Workplace Ambient Gas Detection and Alarm Instruments

GBZ 2.1-2007 Occupational Exposure Limits for Hazardous Factors in the Workplace

GB 4208-2008

GB 16297-1996 Comprehensive Emission Standard for Air Pollutants

GB/T 16157-1996 "Determination of particulate matter and sampling method of gaseous pollutants in exhaust gas from stationary pollution sources"

GB/T 5468-1991

HJ/T 397-2007

HJ/T 76-2017

HG/T 20507-2014

In the event of any conflict between the above standards and the latest standards, the latest standards shall prevail.

System schemes

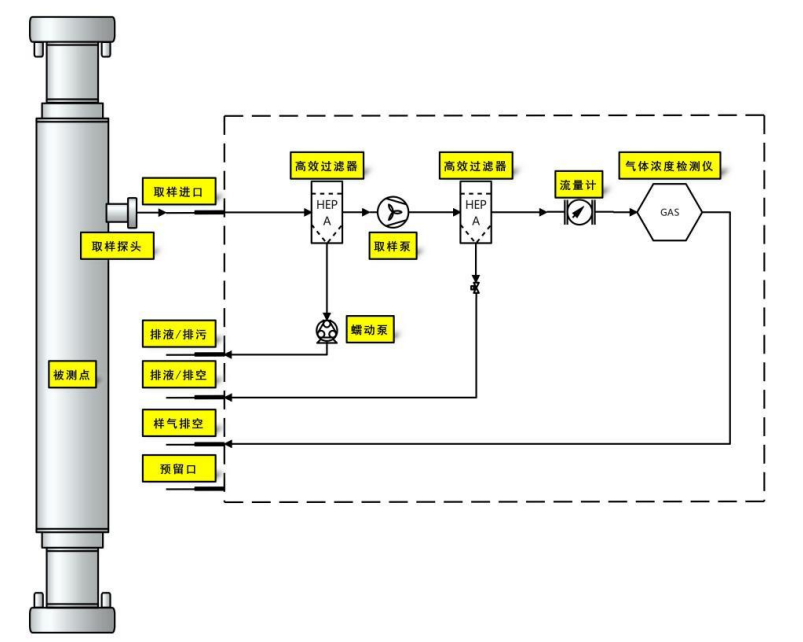

The system is mainly composed of gas sampling subsystem, gas component monitoring subsystem, auxiliary unit, cold-rolled steel box, etc. It is a collection of gas sampling, gas filtration,A standardized, modular and professional Gas Detector system integrating functions such as gas cooling, pipeline purging, flow control, real-time concentration display, and equipment linkageintegrated products; The LEL online monitoring system sends a clean, dry and constant sample gas to the gas detection instrument after active sampling and professional sample pretreatment.

Features

Pre-treatment, high-precision and high-performance LEL online monitoring system, small overall size, easy installation;

Gas pretreatment for harsh environments such as humidity, tar, and dust in complex production environments;

The use of original high-performance sensors, long service life, good anti-interference performance, can monitor a variety of gases at the same time, to achieve high-performance automatic monitoring, monitoringThe measurement data is accurate and stable;

Equipped with infrared remote control, no need to open the cover, to achieve full-featured operation;

Standard configuration of 4-20MA, RS485, a set of relay output signal; It can be easily connected to PLC, DCS, DDC and other industrial control systems, and can also be controlled as a stand-alone machineUse;

Optional DTU, LORA and other wireless modules to realize data parameter collection, real-time upload of gas concentration values to the enterprise DCS system or third-party platform and other servers;

Optional installation of 7-inch industrial touch display, real-time concentration, curve display is more intuitive and clear;

Introduction to the sub-units of the system

1. Flue gas component monitoring subsystem

1.1. Pretreatment system

The sampling pretreatment system of the monitoring system is composed of filter, sampling pump, flow meter, peristaltic pump, condenser (optional) and other devices.

The main tasks are as follows:

1)Sample extraction: The gas in the flue gas is extracted by a sampling pump for measurement by the testing instrument; (Replace with a regulator at positive pressure)

2)Precision filtration: further filter the dust and filter water to ensure that the entire filtration accuracy is below 2μm;

3)Flow adjustment: ensure that the injection flow rate of the instrument is 0.3~0.5L/min to prevent excessive gas volume from damaging the sensor;

4)Condenser: further efficient cooling and dehumidification to prevent temperature and humidity from affecting the sensor; (Optional)

5)Peristaltic pump: auxiliary drainage, prevent water vapor and waste liquid from damaging the sensor;

6) Cooling system: cool down the sample gas to prevent high temperature damage to the sensor; (Optional)

7) Backflushing system: regular purging, way pipeline blockage. (Optional)

(Internal Process Reference Drawing)

1.2 Testing Instruments

SK/MIC-600-LEL-Y: LEL concentration Detector is mainly composed of sensor, interface board and display module. It mainly realizes the measurement and display of organic LEL content parameters and communication functions.

1.2.1 Principle Introduction

Infrared NDIR principle

NDIR infrared gas sensors use a broad-spectrum light source as the light source of the infrared sensor, and the light passes through the measured gas in the optical path and through the narrowband filter.Arrive at the infrared sensor. It is a gas sensing device that uses the relationship between gas concentration and absorption intensity (Lambert-Beer law) to identify gas components and determine their concentrations based on the near-infrared spectroscopy of different gas molecules. It is mainly composed of infrared light source, optical path, infrared sensor, and circuitand software algorithms, mainly used to measure compounds, due to the different internal structures of various substance molecules, it is determined that they are sensitive to different wavelengths of lightSelective absorption of wires, i.e., a substance can only absorb light of a certain wavelength. The absorption relationship of a substance to a certain wavelength of light obeys the Lambert2Beer absorption determinationLaw.

1.2.2 Instrument features

■Intelligent sensor, using intrinsic safety technology, can support multi-gas, multi-range detection, and can provide customized products according to user needs, no need for workIt can realize sensor interchange, offline calibration and zero self-calibration;

■4-20MA, RS485, switching and other signal output, compatible with various secondary meters, data acquisition modules, PLC, DCS systems, can directly drive solenoid valves,Fans, Detectors and other equipment can also drive high-power equipment by driving intermediate relays;

■Large dot matrix LCD display, Chinese or English operation interface optional;

■The Detector can be adjusted to the alarm point, zero point and target point calibration through the remote control without opening the cover, and it can be maintained by a single person;

■Built-in button design + factory reset function to avoid misoperation by personnel;

■The instrument has over-range and reverse polarity protection, which can avoid the danger caused by improper operation;

1.2.3 Instrument function

■Gas concentration measurement and display:The concentration of multi-component gases can be measured at the same time and displayed on the display in real time.

■Calibration and Zeroing:The instrument supports the whole process of automatic zeroing function, which can output the peripheral equipment related to switching control to start the calibration and zeroing process, and can also be used by external devicesTriggers the instrument to start the zeroing calibration process.

1.3 Blowback subsystem (optional)

System components in the flue gas analysis system, such as the backflush subsystem provided by the sampling probe, to prevent the smoke and dust from clogging and contaminating the system equipment components.

The probe blowback relies on a blowback unit installed inside the system, which outputs pulsating high-pressure gas to the parts to be purged under the control of the system blowback commandsource, which blows the dust back into the process piping to prevent clogging.

1.3.1 Technical Indicators

■Purging pressure: (0.4~0.7)MPa can be set;

■Automatic purging cycle: can be set according to dust content;

1.4 Heat Tracing System (Optional)

System components in flue gas analysis systems, such as heat tracing systems in sampling lines, to prevent water vapor from clogging piping equipment components in sub-zero environments.

The heat tracing of the equipment relies on the heat tracing pipe connecting the detection point to the analysis system to maintain a constant temperature of the sampling line, and the heater is placed in the analysis system to maintain the internal protection of the systemMaintain a constant temperature to prevent low temperatures from clogging the system.

Utility conditions

System power supply, cable requirements

■A power supply: AC220V.

■Cable: 4~20mA three-core shielded cable, Wire diameter ≥ 1.0mm;

RS485 four-core shielded cable, Wire diameter ≥ 1.0mm;

When the distance is more than 1000 meters, the diameter of a single wire ≥ 1.5mm, and the shield is connected to the ground.

System air supply requirements (for backflushing, optional)

■Clean, oil-free and water-free instrument air (dew point≤0oC):

■If the customer has a compressed air source, the pressure is required: (0.4~0.7)MPa, the flow rate: 500L/min, and the pressure and flow rate should be stable.

Requirements for sampling point selection

■Vertical pipe section and flue negative pressure area are preferentially selected to ensure the representativeness of the collected samples.

■The measurement position should avoid the elbow of the flue and the part where the cross-section changes sharply. It should be set at least 2 times straight from the downstream direction of the elbow, valve and reducerdiameter, and at a distance of not less than 0.5 times the diameter of the flue in the upstream direction of the above components.

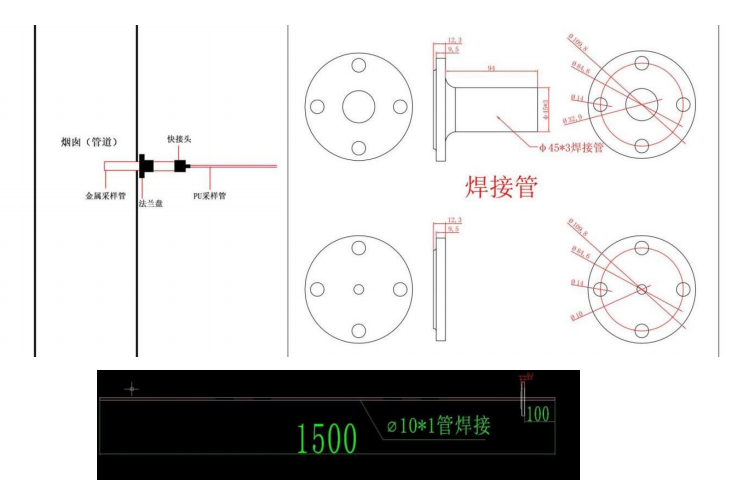

■Installation: φ45 welded flange, probe length 1500mm (can be cut short) or threaded adapter (according to requirements).

Skyeaglee SK-7500-LEL-JY LEL online monitoring systemSpecifications

| LIST | VALUE |

|---|---|

| detection medium | Organic volatile matter in pipeline (explosion measurement) |

| Detection principle | Infrared NDIR |

| Operating temperature | 0~50℃ |

| Operating humidity | ≤ 95% RH (non-condensing) |

| detection range | 0-100%LEL |

| resolution | 0.1%LEL |

| detection Accuracy | ±3%F.S |

| Response time | <25S |

| Power Supply | AC220V |

| output | Standard DC24V output, 4-20mA, RS485 (standard modbus RTU) signal output. Switch output optional |

| show | 2.4 inch LCD display (real-time concentration display, optional with sound and light alarm light) |

| applicable scenario | Generally used for RTO front-end pipeline monitoring to prevent explosion hazards due to high concentration |

| Applicable pipeline conditions | Temperature ≤ 80 ℃, no or trace dust, no or trace water vapor, slightly negative pressure, atmospheric pressure or positive pressure, no explosion-proof requirements |

| Sampling method | pump suction |

| Ambient Pressure | Standard atmospheric pressure +/- 10% |

| Flue gas temperature | Room temperature (higher temperature can be non-standard design) |

| Equipment vibration requirements | ≤100 Hz(0.3m/s) |

| Total power consumption of all devices | Power ≤ 50W |

| Sampling flow rate | 3.5L/Min |

| design life | 2 to 6 years (depending on usage and Sensors principle) |

| Zero drift | No more than +/- 2% F.S. |

| Range drift | No more than +/- 2% F.S. |

| Linearity | No more than +/- 2% F.S. |

Skyeaglee SK-7500-LEL-JY LEL online monitoring system Packing list

LEL online monitoring system X1, stainless steel sampling probe X1, sampling PTFE tube X1, manual X1, certificate X1, factory inspection report X1, remote control X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

SK-7500-LEL-JY

SK-7500-LEL-JY