Xianhua Technology SC-S700 Male Rotation Vacuum Defoaming Stirrer

At the same time, it rotates around, can stir materials within 700 milliliters, can store 5 sets of data, imports and core components of big brands in the industry, and supports functional customization.

xianhuakeji

xianhuakeji-

HUXI HJQ-2 Explosion-proof Pneumatic Stirrer One-word Impeller Slurry 50mm Rod length 300mm

$ 1273.00 -

CHIJIU S312-90 constant speed Stirrer digital display, power is 90W

$ 321.00 -

Qiwei JB-200D Experimental Stirrer (digital display constant speed) 200W

$ 299.00 -

HUXI RWD50 LCD Overhead Stirrer, Three Blades Impeller Slurry 70mm Rod Length 300mm

$ 566.00 -

DADI DJ1C-300 Overhead Stirrer 300W

$ 166.00

Introduction

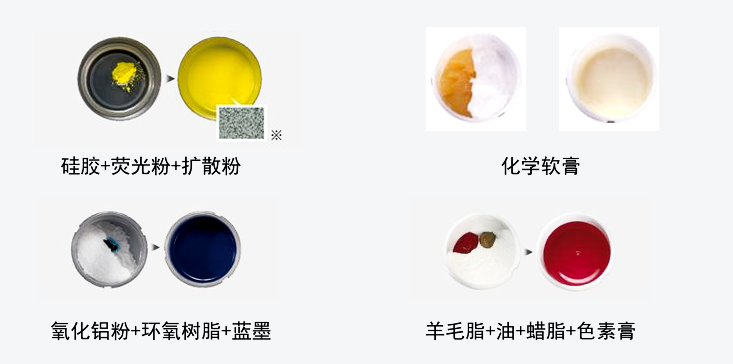

The rotary rotary deaeration mixer can evenly disperse and defoam the material at the same time. It enables high-speed rotation of containers containing materialsRotates in a rpm track. The resulting strong acceleration of the revolution promotes defoaming, while the rotation causes convection of the material in the container, resulting in solidificationDispersion and defoaming in a short period of time. From epoxy glue, silica gel, battery materials, grease, paste, nano carbon tubes, carbon black, LED encapsulants to tonesOintment dispensing in pharmacies, which plays a role in the handling of a wide variety of materials. The equipment has a short processing time, simple operation, high repeatability,Features such as the non-stirring blade structure that eliminates the need for appliance cleaning. It also has a proven track record in emulsification, nano grinding, and vacuum defoaming.

Features

While rotating and revolutionizing, the material is degassed and stirred in a few seconds to minutes.

The rotational speed is mechanically constant, and the speed ratio can be customized for special materials that are not easy to stir.

Equipped with different jigs and cups, it can stir materials up to 700 ml, and can easily meet all requirements from testing to mass production.

It can store 5 sets of data (can be specially customized), and each group of data can be set in 5 stages for different times, which can cope with the mixing and dispersion requirements of most materials.

The important core components are imported and big brands in the industry to ensure the stability of the long-term use of the machine under high load.

At the request of the customer, some functions of the machine can be customized.

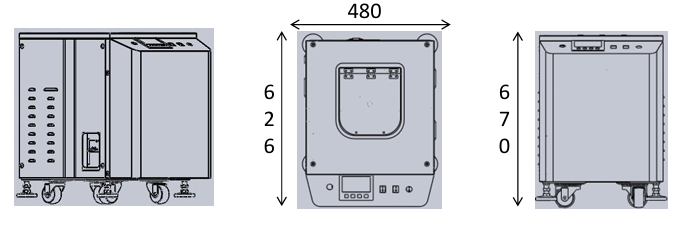

Dimensional drawings

Stirring renderings

xianhuakeji SC-S700 Vacuum Defoaming StirrerSpecifications

| LIST | VALUE |

|---|---|

| Processing Capacity | 700Ml or 800g (decrease or increase depending on stirring material characteristics); 700ml standard container * 2 |

| Rotation speed of motor | 100-2500Rpm stepless speed regulation |

| Rotation ratio | Mechanical constant, revolution rotation ratio 1:0.7 |

| program storage | 5 groups (each group can be adjusted in 5 stages) |

| way | Male Rotation Contactless Mixing & dispersing |

| Power Supply | AC220,50/60Hz |

| Rated Frequency | About 100W in standby, 1.5KW maximum in operation |

| Equilibrating device | Double filler equilibrating, damping module |

| Safety protection | The upper cover sensor, emergency button, and lid opening cannot be started. |

| Dimensions of the whole machine | 626mm(L)*480mm(W)*670mm(H) |

| Machine Weight | 100KG |

| Vacuum range | Atmospheric pressure above -98Kpa, SMC vacuum sensing |

xianhuakeji SC-S700 Vacuum Defoaming Stirrer Packing list

host X1, manual X1, certificate X1, warranty card X1

[Note] Because the manufacturer's packaging may be updated or upgraded, the detailed packaging list shall be subject to the latest standard configuration of the manufacturer.

FAQ

- Several low-end high-speed stirring and dispersing machines that meet GB/T 21868.3 standards

- When do you need to use a disperser instead of a mixer? Difference between disperser and mixer

- Features of acrylic latex paint

- Planetary mixer selection skills

- Principle and Application of Finger Double Planet Stirrer

- Introduction of Working Principle and Application of Electric Oscillator Stirrer

- A Brief Discussion on the Difference between Disperser and Stirrer

- Principle and characteristics of chemical coating mixer

- Explain the difference between Stirrer and Disperser

- Common faults and solutions of Disperser Stirrer

SC-S700

SC-S700